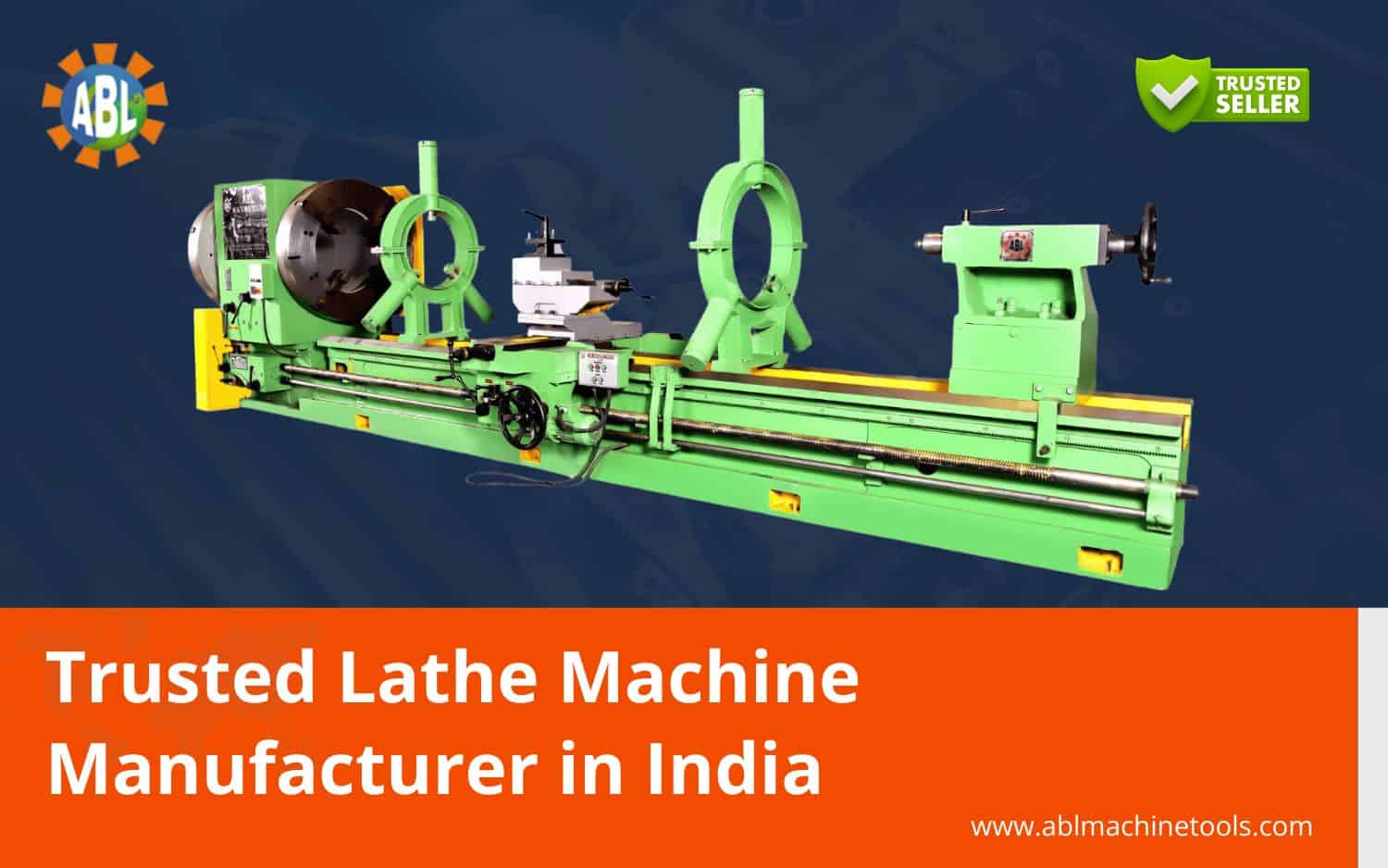

In today’s fast-evolving industrial landscape, precision, efficiency, and reliability are non-negotiable for manufacturers. One key contributor to these objectives is the lathe machine, a cornerstone of metalworking and production processes. For manufacturing businesses, procurement managers, and maintenance engineers, finding a dependable lathe machine manufacturer in India is essential for ensuring long-term productivity and cost efficiency.

This comprehensive guide will explore the technological advancements, applications, and benefits of modern lathe machines. We’ll also examine what makes a manufacturer stand out in the competitive Indian market. Whether you’re investing in your first lathe or upgrading an existing setup, this guide will help you make an informed decision.

Quick Takeaways

- India is a growing hub for high-quality lathe machine manufacturing.

- Precision engineering and automation are redefining industrial applications.

- Choosing the right lathe depends on your application, materials, and scalability.

- Top manufacturers offer extensive after-sales support and customization.

- Understanding CNC integration is critical for modern operations.

- Energy efficiency and cost of ownership are key selection criteria.

1. Understanding Lathe Machines and Their Industrial Importance

Lathe machines are fundamental tools in machining, used to shape metal, wood, and plastic by rotating the workpiece against various cutting tools. They are essential for:

- Turning

- Facing

- Knurling

- Drilling

- Boring

Modern lathes offer enhanced capabilities through automated controls, higher spindle speeds, and better rigidity, making them indispensable across sectors.

Related Tags: industrial lathe uses, turning machine basics

2. Types of Lathe Machines Used in Manufacturing

Each type of lathe serves a unique function. The most common include:

- Engine Lathes: General-purpose, suitable for most workshops

- Tool Room Lathes: Precision work, higher accuracy

- Turret Lathes: Repetitive operations, ideal for mass production

- CNC Lathes: Programmable, high productivity

- Special Purpose Lathes: For tasks like crankshaft machining

3. Applications of Lathe Machines in Modern Industry

Lathe machines are widely used in:

- Automobile Industry: Shafts, pistons, brake drums

- Aerospace: Precision components

- Metal Fabrication: Structural components

- Medical Equipment Manufacturing

Example: ABL Machine Tools supplies machines used in the fabrication of high-tolerance aerospace parts.

Related Tags: industrial lathe uses, turning machine basics: lathe machine for automotive industry, lathe in aerospace manufacturing

4. Why Choose a ABL Lathe Machine Manufacturer in India?

India has emerged as a reliable hub for machine tool production due to:

- Competitive pricing

- Skilled engineering talent

- Technological advancement

- Export quality compliance (ISO, CE standards)

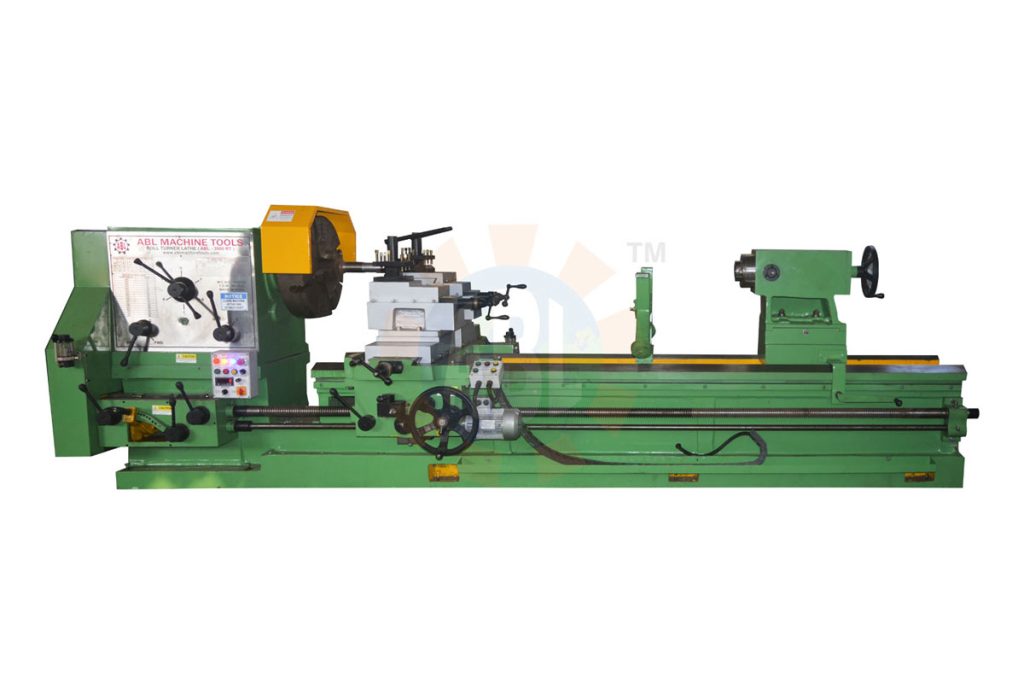

5. Key Features of Precision-Engineered Lathe Machines

What defines a “precision-engineered” lathe?

- High spindle accuracy (≤0.005 mm)

- Hardened and ground bed ways

- Vibration damping

- Lubrication systems

- Digital readouts and automation

Related Tags: high precision lathe, lathe bed hardness, spindle tolerance

6. The Role of CNC in Lathe Machine Automation

CNC (Computer Numerical Control) enhances productivity with:

- Repeatable operations

- Reduced human error

- 24/7 operation

- Easier prototyping

Case Study: A mid-sized auto-parts manufacturer reduced cycle time by 40% after integrating CNC lathes.

Related Tags: CNC lathe productivity, automated lathe machine

7. Factors to Consider When Selecting a Manufacturer

- Product quality and certifications

- Warranty and support

- Lead time

- Availability of spares

- Testimonials and case studies

8. Cost vs. Performance: Making the Right Investment

Don’t just compare prices. Evaluate:

- Tool life

- Downtime frequency

- Production volume capacity

Related Tags: cost-effective lathe, budget vs premium lathe machines

9. Maintenance and After-Sales Support: What to Expect

Reliable manufacturers offer:

- Preventive maintenance plans

- Training for operators

- Quick service response

ABL Machine Tools, for example, offers AMC packages and remote diagnostics.

Related Tags: lathe AMC support, machine downtime solutions

10. Energy Efficiency and Environmental Impact

Modern lathes are built for:

- Low power consumption

- Eco-friendly coolants

- Noise reduction

Tip: Energy-efficient lathes can reduce power usage by 15–25%.

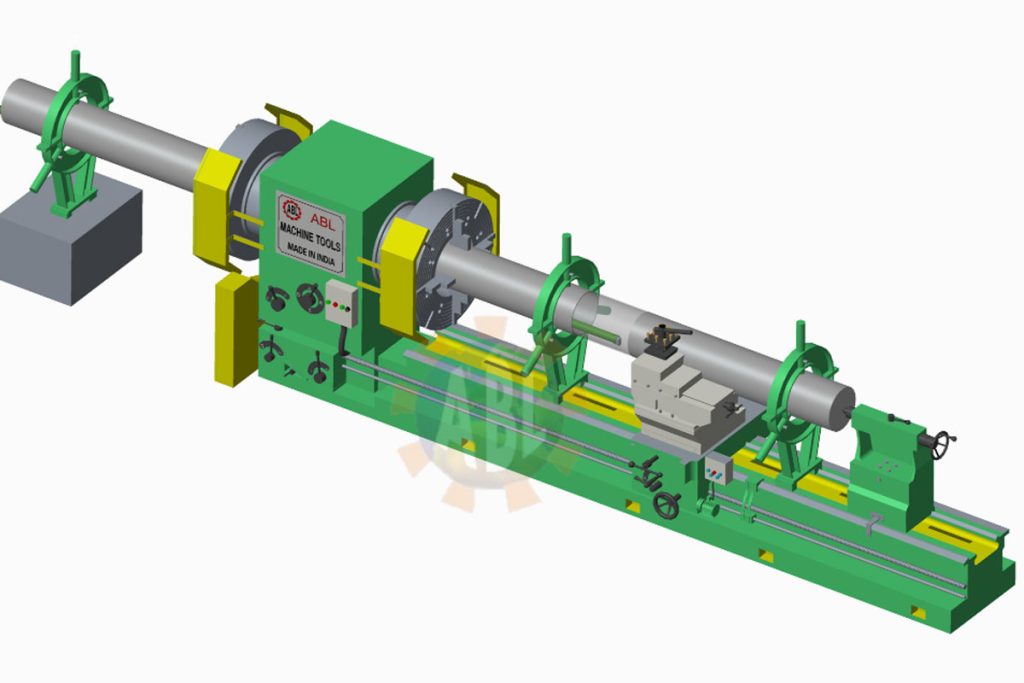

11. Custom-Built Solutions for Niche Applications

Certain industries need customized lathe setups:

- Textile rollers

- Oil & gas flanges

- Defense parts

ABL offers special-purpose lathes with client-specified spindle bores and bed lengths.

Related Tags: custom lathe solutions, lathe for oil & gas

12. Real-World Case Studies: Success Stories from Indian Manufacturers

- Case A: Automotive SME increased output by 30% post-installation

- Case B: Aerospace firm achieved ±3 micron tolerance consistently

13. Future Trends in Lathe Technology and Smart Manufacturing

- IoT integration

- Predictive maintenance

- Cloud-based monitoring

- AI-assisted machining

Related Tags: smart lathe machines, Industry 4.0 in machining

14. How to Get the Best ROI from Your Lathe Investment

- Invest in training

- Monitor KPIs like OEE (Overall Equipment Effectiveness)

- Use OEM-recommended spares

A precision lathe machine is more than just equipment—it’s a strategic asset. Whether you’re in procurement, operations, or supply chain management, understanding how to choose and utilize a lathe machine can have long-term productivity and profitability implications. Indian manufacturers like ABL Machine Tools have proven that world-class machinery doesn’t have to come with an overseas price tag.

Explore your options, ask questions, and don’t settle for off-the-shelf solutions when customized excellence is available.

Contact ABL Machine Tools today to discuss your machining needs with our experts.

FAQs

1. What are the key benefits of using a CNC lathe over a manual lathe? CNC lathes offer higher precision, faster production, and less dependency on manual labor. They are ideal for mass production with consistent quality.

2. How do I choose a reliable lathe machine manufacturer in India? Look for ISO certifications, client testimonials, in-house manufacturing facilities, and robust after-sales support.

3. Can lathe machines be customized for specific industries? Yes, many manufacturers offer customizations like bed length, spindle bore, or tooling for niche industries like oil & gas or aerospace.

4. What maintenance is required for lathe machines? Regular lubrication, spindle alignment checks, and preventive servicing every 6–12 months are recommended.

5. Are Indian lathe machines export quality? Absolutely. Reputed brands comply with CE and ISO standards and export globally to the Middle East, Africa, and Southeast Asia.