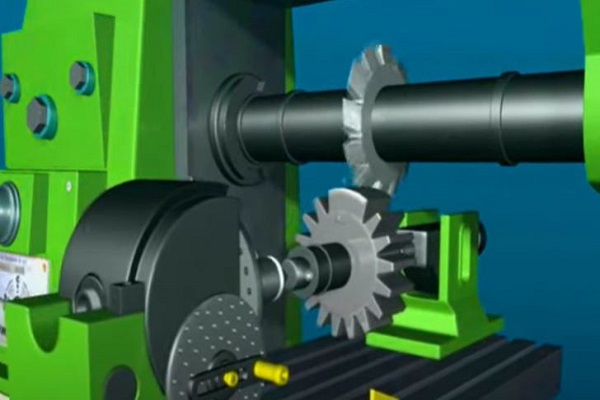

ABL Lathe Machines are amongst the most trusted lathes ensuring heavy & precise cutting. The machines are well known for precision Taper Turning applications. Taper turning is the turning process in which the cutting tool moves at an angle to the axis of the workpiece so that a tapered shape is obtained in the workpiece. In a tapered piece, the diameter of the workpiece changes uniformly from one end to another. The workpiece can be tapered from inside or outside. On ABL Lathes, heavy duty Taper Turning Attachment comes fitted with the Lathe Machine for easy operations & handling

WHAT IS TURNING ON A LATHE?

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. ABL Lathes are designed & built for heavy & precise turning applications on the machines.

Usually the term “turning” is reserved for the generation of external surfaces by this cutting action, whereas this same essential cutting action when applied to internal surfaces (holes, of one kind or another) is called “boring”. Thus, the phrase “turning and boring” categorizes the larger family of processes known as lathing. The cutting of faces on the workpiece, whether with a turning or boring tool, is called “facing”, and may be lumped into either category as a subset.

Turning Length & Diameter may vary for different users. ABL is in the position to offer a wide range of Heavy Lathes for precise & mass production turning applications.

TAPER TURNING METHODS ON LATHE MACHINE

Like any reputed Lathe Machine, ABL Lathe Machines are well capable to carry Taper Turning on the Lathe Machine using different methods. Some of the methods are –

- Form tool method.

- Tailstock set over method.

- Compound rest method.

- Taper turning attachment method.

- Combining feeds method.

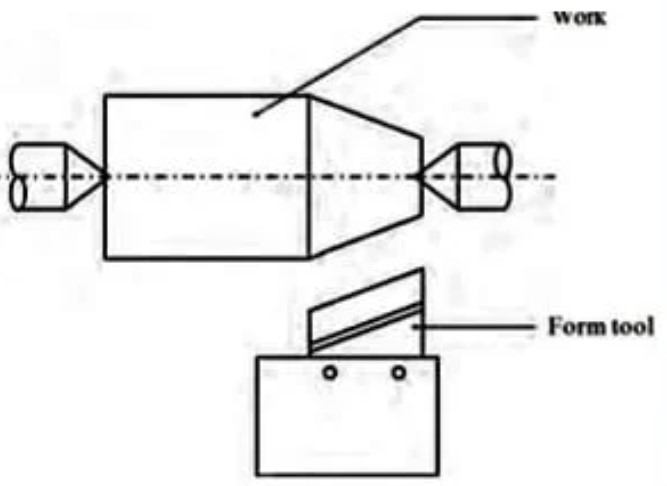

FORM TOOL METHOD

The form tool methods are one of the simplest methods to create a short taper. In this method, a broad form tool with a straight cutting edge is set to the work at a half taper angle & is fed directly into the workpiece. The tool used in this method is called the taper turnings form tool. The tool itself is used in a tapered shape, creating a tapered workpiece.

In this method, the length of the taper should be less than the length of the tool cutting edge. Since the entire edge removes the metal, it will create huge vibrations and therefore requires a large force. This method is performed to reduce the required vibration and force at a slow rate.

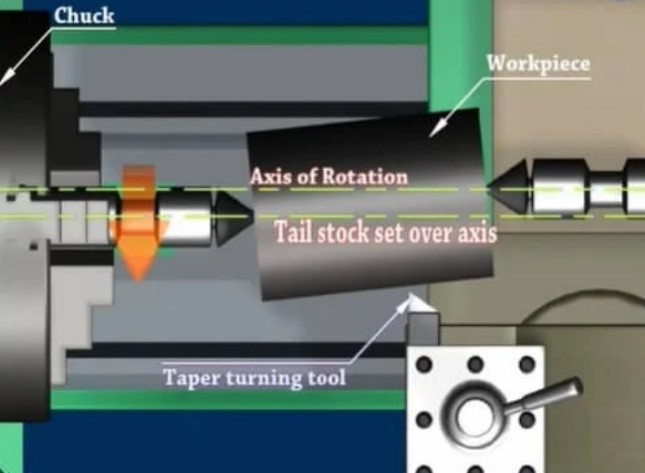

TAIL STOCK SET OVER METHOD

This method is commonly used when the angle of the tapers is very small. In this method, the axis of rotation of the workpieces is shifted to the axis of the lathe at half an angle to the taper.

The workpiece is placed between the live centre and the dead centre. The tailstock is moved upright in a cross direction that is in the direction of the lathe axis by the turning set-over method. The tailstock is locked in an upward or downward direction to allow the workpiece to tilt, and therefore the taper bend can be ejected.

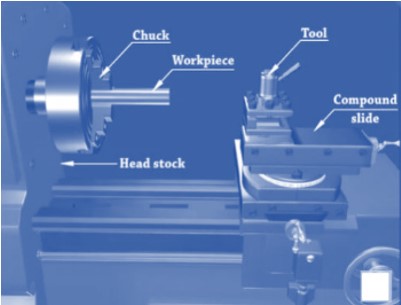

COMPOUND REST METHOD

This method is typically used to produce short and steep cones. In this method, the compound rest is rotated at the required angle and held in position. The compound rest can be rotated up to 45 degrees. The workpiece is held in the chuck & will be rotated in the lathe axis.

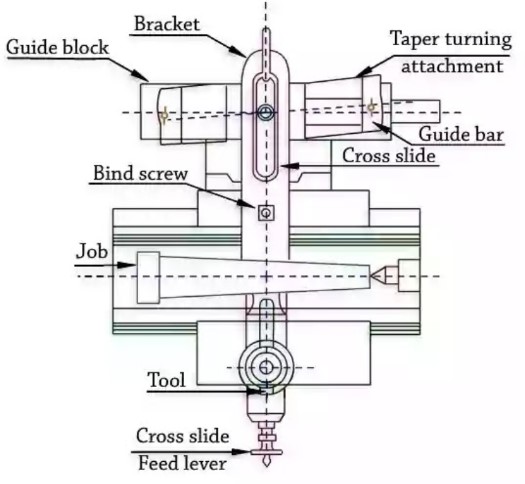

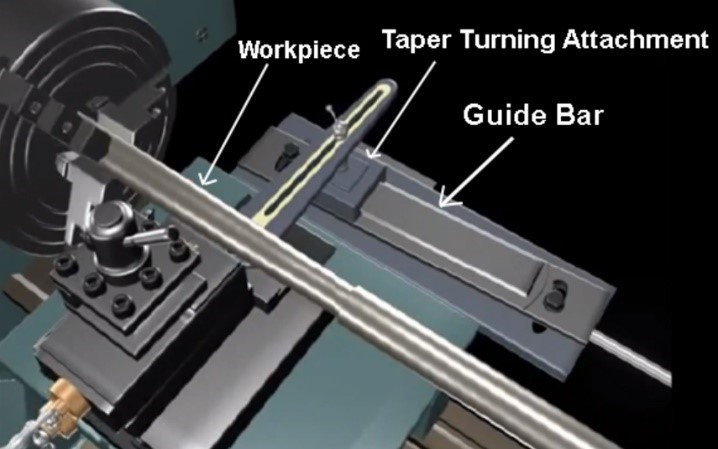

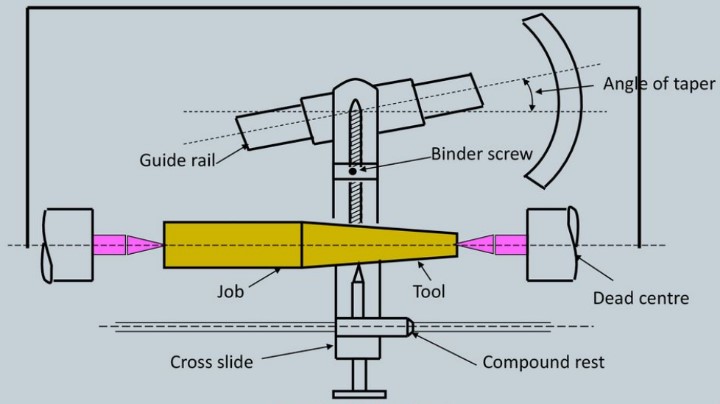

TAPER TURNING ATTACHMENT

Taper Turning Attachment comes as an optional attachment with ABL Lathe. In this method, the taper bend is performed using an attachment. This attachment has a guide bar, & this guide bar is usually placed in the center. The guide bar can swing at any required angles of the taper. The tool moves parallels to the guide bar.

A guide bar is used to guide the tool at required angles. The guide bar has a scale of degrees. The guide bar can be rotated on both sides at a maximum angle of 10 °. The angle required for taper turning is achieved by rotating the guide bar.

In this method, the workpieces are held in a chuck. It has a guide block that attaches to the back end of the cross-slide and runs on the guide bar.

In this method, the guide bar is set at an angle at which the workpiece is to be taped. By using the taper turning attachment method, taper turning of any size can be performed easily. The job is held either in 3 Jaw or 4 Jaw Chuck or in the centers, i.e., dead and Live center in the tempering process. The depth of cut is given by the compound rest handwheel.

COMBINING FEED METHOD

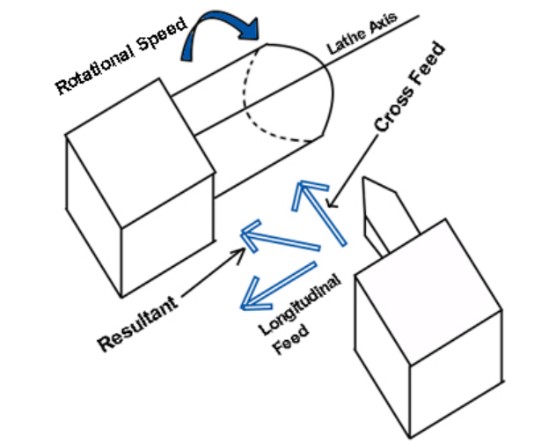

It is an advanced tempering method. In some lathe machines, both longitudinal and cross feeds can be mounted simultaneously, causing the tool to be moved in a diagonal path and taper bent.

The diagonal path followed by the instrument is the result of two feeds. The direction of the tool can be changed by varying the feed rate of longitudinal and crossfeed. This method can only be operated by a skilled operator because it is very easy to do wrong in this method.