ABL MACHINE TOOLS is amongst the leading manufacturers & exporters of widest range of Heavy Workshop Machines like – CNC & Conventional Lathes, Drills, Mills, Borers etc. with supplies to different sectors like Oil & Gas, Railways, Defense etc.

Milling is the cutting process used in various applications and it is the most important process in industries. Have you heard about milling machines? Milling machines are used for drilling, boring and producing slots. They are also used in the process of shaping metals and irregular surfaces. Here, the question arises which milling machine you should select? In this article, we will discuss the two main types of milling machines. We select milling machines on the basis of factors such as feed rates, cutting speed, the milling feed direction, etc. Here we will discuss the main difference between horizontal and vertical milling machines in detail.

Basically, milling machines are categorized into two parts:

Vertical Milling Machine & Horizontal Milling Machine

MAJOR DIFFERENCE – Vertical Milling & Horizontal Milling Machine

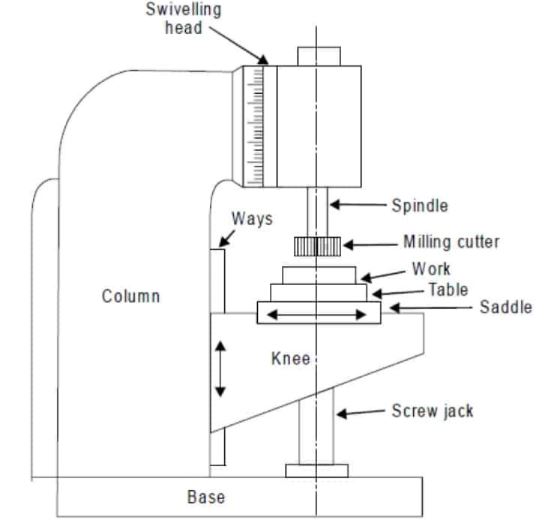

In Vertical Milling Machine, the spindle axis is aligned in a vertical direction. The base of vertical milling machines is made up of cast iron as it has higher compressive strength. The screw jack is attached to the base and it moves in the vertical direction. Also, this machine is used in a larger number of applications as we can use various cutters according to our requirements. The drawback of the vertical milling machine is that it has low efficiency.

The vertical milling machine is again sub-divided in two types:

(a) Bed Mill: In bed mills, spindle always moves parallel to its own axis while the table moves perpendicular to the axis of the spindle.

(b) Vertical Mill Head: In vertical mills, spindle is in stationary position and table is moved in such a way that it will always perpendicular and parallel to the axis of the spindle during the cutting operation.

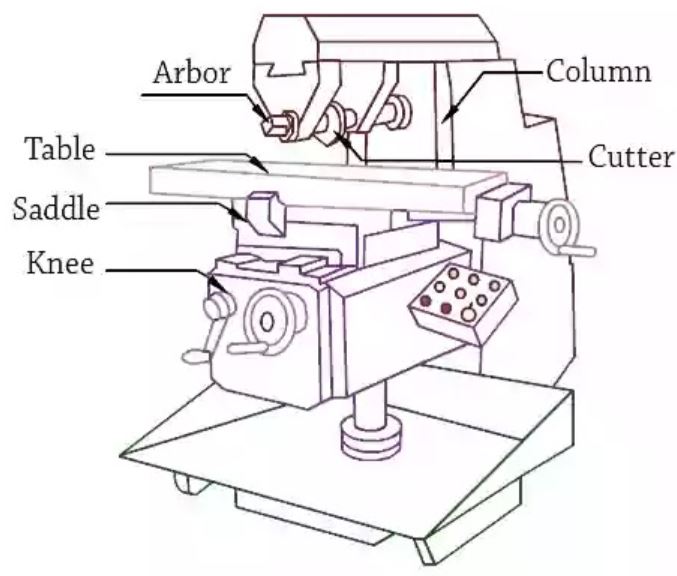

WHEREAS, in a Horizontal Milling Machine, the spindle axis is aligned horizontally.

The base of the horizontal milling machine is made up of grey cast iron. In this machine, an arbor is used and it is inserted in a spindle nose. The gear arrangement is inside the column. Above column, we have overarm. An arbor is supported by yoke and arbor support. An arbor is chosen according to the internal diameter of the cutter. Arbor and spindle are both different. Arbor is an extension and is fitted inside the spindle and it transfers the rotational motion of spindle to the cutter. This type of machine gives us an excellent finishing and the cutting chips are removed easily.

ABL Machine Tools

Please send us your inquiries for our MILLING MACHINES at :

ablmachines@gmail.com or What’s App: +91-9890012456

Thanks for the info