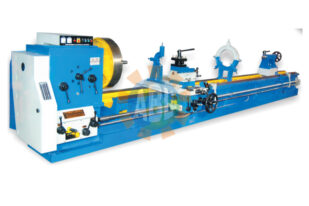

GENERAL MACHINING / METAL REMOVAL / THREADING / FACING / TAPER TURNING

Extra Heavy, All Geared Horizontal Lathe Machines are designed to provide optimum performance with extra heavy cutting power with versatility and used in wide range of industrial sectors like – general workshops, power plants, cement, steel plants, paper mills, shipyards, foundries etc. The lathe is equipped with universal gear box that provides large range of threads without changing transposing gears. Inch, Metric, Module and Diametral Pitch. Threads are selected through conveniently located lever. Several ranges of Spindle Speeds in steps & step – less are also provided for various job applications.

STANDARD ACCESSORIES

- 4 Jaw Chuck

- Electricals

- Steady & follow rest

- Dead and Live Centres

- Face & chuck plate

- Chip Tray

- Coolant System

- Machine Lamp

- Foundation Boalt Kit

- Chuck Guard

- Instruction Manual

OPTIONAL ACCESSORIES

- Digital Readout Sys (DRO)

- Taper Turning Attachment

- Keyway Cutting Attachment

- Chip Conveyor System

- Tool Post Grinder

- Variable Speed Drives

- Motorized Saddle

- Motorized Tail Stock

- Large Dia face plate

- 3 Jaw Chuck

- 4 Jaw Chuck at tail stock

- Additional Extra Heavy Steadies

SALIENT FEATURES

- High quality cast iron bed, head,Tail stock, Saddle etc.

- Single Piece bed casting ensures high rigidity, Alloy Steel & Hardened Gears, Various Range of thread option in metric & inches.

- Geometrical Accuracies confirm to IS/DIN or it’s equiv. intl. standards.

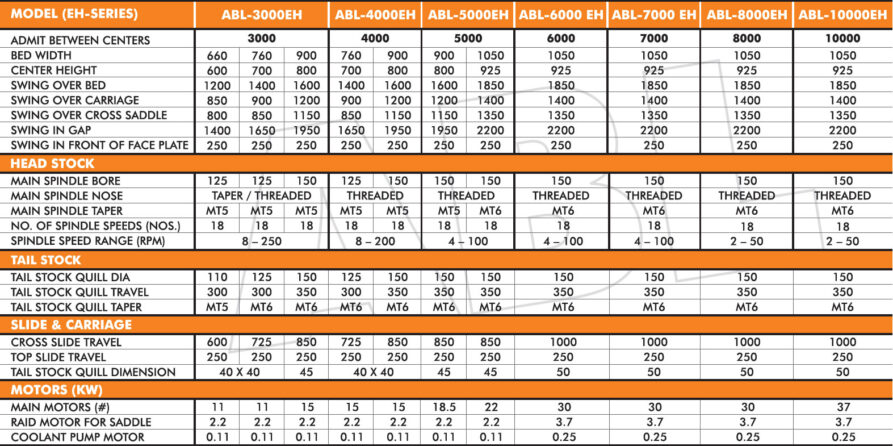

SPECIFICATIONS & DATASHEET DOWNLOAD

Please fill up the form below to download the file.

ASK FOR A QUOTATION