HYDRAULICALLY OPERATED / PRECISION OD GRINDING

Hydraulic Centreless Grinding is an OD (outer diameter) grinding process. In difference from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centres, the workpiece is not mechanically constrained during centreless grinding.

Therefore, the parts to be ground on a centreless grinder do not need centre holes, drivers or work head fixtures at the ends.

STANDARD ACCESSORIES

- Grinding wheel with flange

- Regulating wheel with flange

- Coolant pump with tank

- Hydraulic tank with pump

- Work rest blade for through feed grinding

- Hand pump lubrication for slides

- Machine lamp

- Splash guards

- A.C. drive for regulating wheel head

- Instruction manual

- Tool kit

- Micro feed fine adjustment for depth of cut

- Template truing slides for profile dressing

- Hydrodynamic bush bearing for GW head

- Bush bearing for RW head

- Foundation Bolt Kit

- Instruction & Maintenance Manual

OPTIONAL ACCESSORIES

- Motorized centralized lubrication for slides

- A.C. drive for grinding wheel head

- Wheel balancing stand with arbour

- Additional grinding wheel flange

- Additional regulating wheel flange

- Additional work rest blade through feed

- Additional work rest blade infeed

- Magnetic coolant separator

- Paper cum magnetic coolant separator

- Anti-vibration pads

- Hydraulic oil cooler

- Profile templates

- Vibratory bowl feeder

- Bar feeder for long bar grinding

- Auto infeed grinding with hydraulic cylinder

- Auto ejector for infeed grinding hydraulic

- Auto ejector for infeed grinding pneumatic

- Auto lifter for infeed grinding

- Auto loading attachment for infeed

- Automatic feeder for through feed grinding

- Automatic balancing for grinding wheel

SALIENT FEATURES

- Designed for both through-feed & in-feed grinding

- Microfeed-fine adjustment for depth of cut

- Minor taper adjustment without dressing

- Template truing devices fitted with linear slides

- Grinding wheel & regulating wheel head fitted with precision roller/hydrodynamic bearings

- Regulating wheel variable speed drive

- Separate motorized lubrication system for grinding wheel head with safety float switch

- Precision ball screw for depth of cut

- Dressing slides hardened ground and protected with way wipers

- Grinding wheel duly balanced and easy to load and unload

- Apart from above, machines are compact, rigid and stable in design

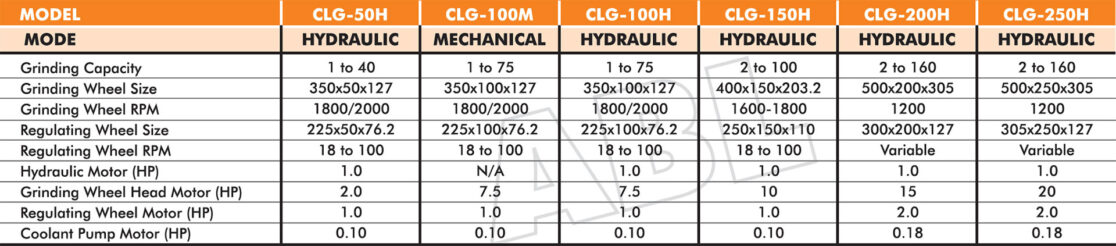

SPECIFICATIONS & DATASHEET DOWNLOAD

Please fill up the form below to download the file.

ASK FOR A QUOTATION