HYDRAULICALLY OPERATED / RUBBER & STEEL ROLL PRECISE GRINDING

Hydraulic Universal Cylindrical Grinding Machines are ideally suited to perform repetitive grinding operations or small quantity production with equal ease. It can grind both Rubber and Steel by only changing the Grinding Plate. Features of our existing range of machines. All models have hydraulic and mechanical table traverse. Wheel head rapid approach for theoperating conveniently. In all models, variable speed of work head and internal grinding spindles facilities are available. We use antifriction Turcite “B” slid -way material on the slides in all our models. Hand – operated lubrications pump for sufficient lubrication of slides. Surface finish 2 microns (improved Ra values can be obtained by using selected grades of grinding wheel applicable to material to be ground.). The higher Grinding Length & Dia. are available as well.

STANDARD ACCESSORIES

- Portable Control Push Button Pendent

- Coolant pump fitted on tank

- Lubrication Pump

- Diamond Dresser

- Dead Centre & Tool kit

- Foundation Bolt Kit

- Instruction & Maintenance Manual

- All dimensions are in MM, unless specified Higher Sizes shall be provided on request

OPTIONAL ACCESSORIES

- Internal Grinding Attachment

- Balancing Stand

- Balancing Mandrel

- Three Point Steady Rest

- Two-point Steady Rest

- Radius Truing Device

- Spare Wheel Flange

- Independent Four Jaws Chuck

- Magnetic Coolant Pump

- Grinding Gauge

SALIENT FEATURES

- “ABL” Universal Cylindrical Grinding Machines have Grinding Wheel Head Swivelling

- Facility and Internal grinding attachment to perform various grinding

- Operations like Plunge, Traverse, Internal, Angle, Face, Taper, Profile

- Slide ways coated with ‘TURCITE-B’

- Hydrodynamic bearings for wheel spindle

- Internal grinding attachment with independent drive motor

- Centralized Lubrication System

IMAGES GALLERY

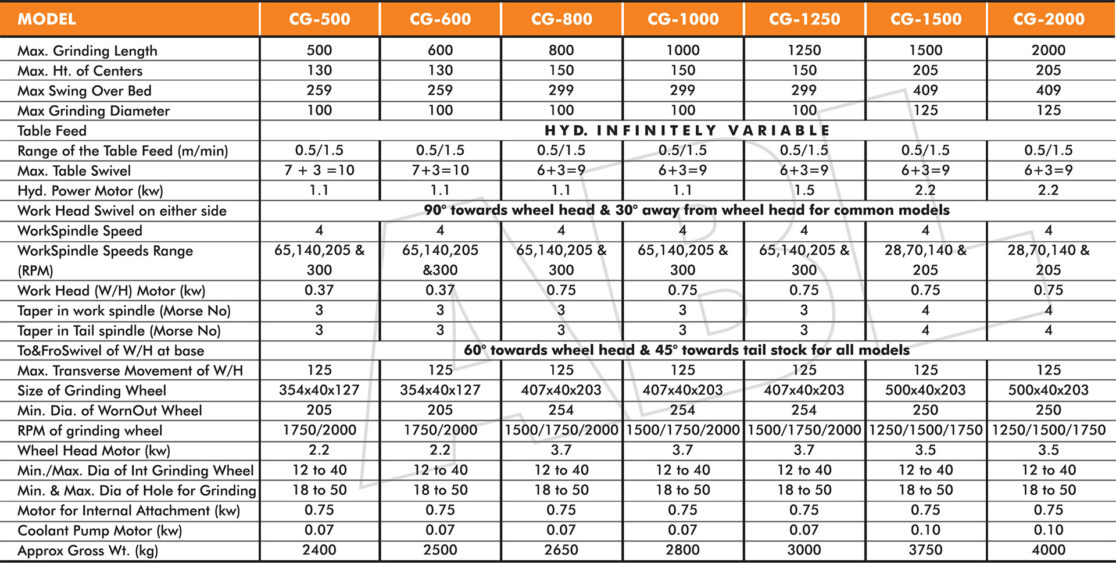

SPECIFICATIONS & DATASHEET DOWNLOAD

Please fill up the form below to download the file.

ASK FOR A QUOTATION