CNC Flat Bed Lathe

CNC Flat Bed Lathe Machines Manufacturers in India

CNC Flat Bed Lathe Machine is “HAYAT” series of ABL which means “life”. As the name suggests, the machine adds life to the heavy-duty workshops for wide range of metal removal & other applications. HAYAT Lathes offer heavy-duty, high-precision Flat Bed CNC Lathes designed to effortlessly manage the workpieces in the industry. Embrace the power to expand your machining capabilities and transform challenges into routine.

FLAT BED CNC LATHE RANGE

Bed Width - 500

Admit Between Centre - 1500 mm to 5000 mm

| Overview | ||||

|---|---|---|---|---|

| Hayat Series / CNC Lathe | ABL-SY25 | ABL-SY30 | ABL-SY35 | ABL-SY40 |

| Swing Over Bed | 660 MM (26”) | 770 MM (30”) | 890 MM (35”) | 1000 MM (40”) |

| Swing Over Cross Slide | 370 MM (14.5”) | 480 MM (19”) | 600 MM (24”) | 700 MM (28”) |

| Center Height | 330 MM (13”) | 385 MM (15”) | 450 MM (18”) | 500 MM (20”) |

| Bed Width | 500 MM (20”) | 500 MM (20”) | 500 MM (20”) | 500 MM (20”) |

| Spindle Bore | A2-11 (4”) | A2-11 (4”) | A2-11 (6”) | A2-11 (6”) / A2-15 (9”) |

| Distance Between Centers | 1500 / 2000 / 3000 MM | 1500 / 2000 / 3000 / 4000 / 5000 MM | ||

Application Areas

Submersible Pumps, Oil & Gas, Pump & Valves, Motor Shafts, Rotors, Forgings, Tie Rods Etc.

Product Specifications

| MODEL | ABL-SY25 | ABL-SY30 | ABL-SY35 | ABL-SY40 |

|---|---|---|---|---|

| CAPACITY | ||||

| Swing Over Bed | 660 MM | 770 MM | 890 MM | 1000 MM |

| Swing Over Cross Slide | 370 MM | 480 MM | 600 MM | 700 MM |

| Centre Height | 330 MM | 385 MM | 450 MM | 500 MM |

| Bed Width | 500 MM | 500 MM | 500 MM | 500 MM |

| Distance Between Centres | 1500/2000/3000 MM | 1500 / 2000 / 3000 / 4000 / 5000 MM | ||

| SPINDLE | ||||

| Spindle Nose/ Bore | A2-11 (4”) | A2-11 (4”) | A2-11 (6”) | A2-11 (6”) / A2-15 (9”) |

| Speed Range | L2: 25~75 rpm | L2: 25~75 rpm | L2: 25~53 rpm | L2: 15~50 rpm |

| L1: 76~165 rpm | L1: 76~165 rpm | L1: 54~118 rpm | L1: 51~110 rpm | |

| H2: 166~540 rpm | H2: 166~540 rpm | H2: 119~386 rpm | H2: 111~260 rpm | |

| H1: 541~1200 rpm | H1: 541~1200 rpm | H1: 387~860 rpm | H1: 261~600 rpm | |

| Spindle Centre | MT5 | MT5 | MT5 | MT5 |

| Width of Slide | 280 MM | 280 MM | 280 MM | 280 MM |

| Turret Type | H4 or V8 Hydraulic | H4 or V8 Hydraulic | H4 or V8 Hydraulic | H4 or V8 Hydraulic |

| Tool Size | H4 or V8, 25×25 | H4 or V8, 25×25 | H4 or V8, 25×25 | H4 or V8, 25×25 |

| X-Axis Travel | 450 MM | 450 MM | 450 MM | 450 MM |

| Z-Axis Travel | 1380/1890/2900 | 1380 / 1890 / 2900 / 3900 / 4900 MM | ||

| X-Axis Rapid Travel | 5M / MIN – 32xP5 | 5M / MIN – 32xP5 | 5M / MIN – 32xP5 | 5M / MIN – 32xP5 |

| Z-Axis Rapid Travel | 6M / MIN – 35xP10 | 6M / MIN – 35xP10 | 6M / MIN – 35xP10 | 6M / MIN – 35xP10 |

| TAIL STOCK | ||||

| Quill Diameter | Standard Ø: 105 MM (4”) / Optional Ø: Rotating Quill 145 MM (5.7”) | |||

| Quill Travel | 200 MM | 200 MM | 200 MM | 200 MM |

| Quill Taper | MT6 | MT6 | MT6 | MT6 |

| MOTORS | ||||

| X-Axis Servo Motor | 1.6 Kw | 1.6 Kw | 1.6 Kw | 3.0 Kw |

| Z-Axis Servo Motor | 3.0 Kw | 3.0 Kw | 3.0 Kw | 4.0 Kw |

| Spindle Motor | Standard: 15/18.5 Kw : Optional: 18.5 / 22 Kw, 22 / 26 Kw | |||

| Coolant Pump | 0.45 Kw | 0.45 Kw | 0.45 Kw | 0.45 Kw |

| Hydraulic Pump | 1 Kw | 1 Kw | 1 Kw | 1 Kw |

| CNC Controllers | FANUC / Siemens | FANUC / Siemens | FANUC / Siemens | FANUC / Siemens |

Standard Accessories

- Manual 4 Jaw Chuck

- CNC Controller & Motors

- 4” Spindle Bore

- Auto 4 Steps Spindle Speeds

- H4 or V8 Turret

- Auto Coolant System

- Lubrication System

- Splash Guard

- Manual Tailstock

- Work Light

- Maintenance Tool Box Kit

Optional Accessories

- Larger Spindle Bore

- Spindle Oil Chiller

- Hydraulic Chuck

- C-Axis or Spindle 1/15 Deg. Indexing

- Driving Tool Turret

- Steady Rest

- Follow Rest

- Special Boring Bar Holder

- Higher Coolant Pressure

- Chip Conveyor

- Hydraulic Tailstock with Rotating Quill

- Transformer

Salient Features

HAYAT Series CNC Flat Bed Lathes from ABL are extensively used in shaping various parts. These computer-controlled lathes are the workhorses of the machining world, renowned for their ability to handle heavy-duty tasks with precision. These lathes excel in turning, milling, and drilling metals and other materials, making them indispensable multitaskers in the machining industry. These machines play a pivotal role in crafting components for a wide range of machinery and devices.

Video Gallery

Image Gallery

3 Jaw Manual Chuck

4 Jaw Manual Chuck

H4 Turret

V8 Turret

Live Tooling Turret

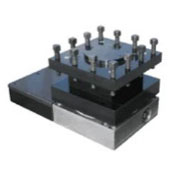

Quick Change Tool Post

Chip Conveyor System

Boring Tool Holder

Hydraulic Tail Stock

Oil Cooler

Heat Exchanger

Dead Centre

Live Centre

ENQUIRE NOW

Wide Range of CNC Flat Bed Lathe Machines

In today’s competitive manufacturing landscape, precision, speed, and efficiency are the driving factors behind industrial growth. Among the advanced machining solutions, CNC Flat Bed Lathe Machines play a crucial role in delivering high-quality turning operations across a wide variety of industries. As one of the leading CNC Flat Bed Lathe Machine manufacturers in India, ABL Machine Tools offers world-class solutions that combine cutting-edge technology with robust engineering.

A CNC flat bed lathe is designed for heavy-duty applications where large components and longer workpieces need to be machined with accuracy. Unlike traditional lathes, these machines are equipped with Computer Numerical Control (CNC) systems, ensuring consistent performance, automated functions, and reduced operator intervention. This not only enhances productivity but also minimizes errors and material wastage.

ABL Machine Tools manufactures CNC flat bed lathes that meet both domestic and international industry standards. With exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, the company has established itself as a trusted global supplier. Each machine is engineered with advanced features like rigid bed construction, high spindle torque, powerful servo motors, and user-friendly CNC controls, making them suitable for industries such as oil & gas, automotive, aerospace, shipbuilding, and general engineering.

One of the key strengths of ABL lies in its ability to provide customized solutions. Every manufacturing process is unique, and ABL Machine Tools specializes in designing custom-made CNC flat bed lathe machines to match specific production goals. Whether it’s high-volume production or specialized one-off components, their machines are built to deliver unmatched reliability and performance.

By investing in ABL’s CNC flat bed lathes, manufacturers gain a competitive edge through:

- Superior precision and accuracy in machining

- Reduced downtime with robust construction

- Enhanced productivity through automation

- Long service life and low maintenance costs

- Tailor-made options to suit varied applications

With a proven track record of innovation, ABL Machine Tools stands as a pioneer in advancing India’s machine tool industry. Their CNC flat bed lathes are more than just machines—they are productivity-enhancing assets designed to support modern manufacturing challenges.

If you are searching for a reliable CNC Flat Bed Lathe Machine manufacturer in India, ABL Machine Tools delivers solutions that combine durability, efficiency, and advanced technology to drive your business forward.

CNC Flat Bed Lathe Machines Manufacturers in Saudi Arabia, CNC Flat Bed Lathe Machines Manufacturers in UAE, CNC Flat Bed Lathe Machines Manufacturers in Qatar, CNC Flat Bed Lathe Machines Manufacturers in Kuwait, CNC Flat Bed Lathe Machines Manufacturers in Bahrain, CNC Flat Bed Lathe Machines Manufacturers in Oman, CNC Flat Bed Lathe Machines Manufacturers in Egypt

FAQ – CNC Flat Bed Lathe Machines

What is a CNC Flat Bed Lathe Machine?

A CNC flat bed lathe is a heavy-duty machine tool designed to perform turning operations on large and long workpieces. It uses Computer Numerical Control (CNC) technology for precision, automation, and consistent machining results.

What are the main applications of CNC flat bed lathes?

These machines are widely used in:

- Oil & gas industry (pipes, valves, fittings)

- Automotive and aerospace component manufacturing

- Shipbuilding and heavy engineering

- General engineering workshops

- Energy and power equipment manufacturing

How does a CNC flat bed lathe differ from a slant bed lathe?

- Flat Bed Lathe – Ideal for larger, heavier workpieces with robust construction, offering flexibility in machining.

- Slant Bed Lathe – Best for high-speed precision machining of smaller parts, with faster chip removal and higher efficiency.

What are the advantages of using CNC flat bed lathes?

- High rigidity and durability for heavy-duty operations

- Consistent accuracy with CNC automation

- Ability to handle longer and larger workpieces

- Reduced operator fatigue and errors

- Customizable to suit specific industry needs

Can CNC Flat Bed Lathes be customized?

Yes. ABL Machine Tools designs and manufactures custom-made CNC flat bed lathes tailored to customer requirements—such as spindle size, bed length, automation level, and control systems.

Why choose Indian manufacturers for CNC flat bed lathes?

Indian manufacturers like ABL Machine Tools are globally recognized for their cost-effective, durable, and technologically advanced machines. Their machines are exported to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, proving international trust and quality.

What kind of maintenance is required for CNC flat bed lathes?

Routine checks include spindle lubrication, bed alignment, inspection of CNC control systems, and cleaning of chips. Preventive maintenance ensures long machine life and continuous performance.

Does ABL Machine Tools provide after-sales support?

Yes. ABL Machine Tools offers full after-sales service, including operator training, spare parts supply, maintenance support, and technical assistance.