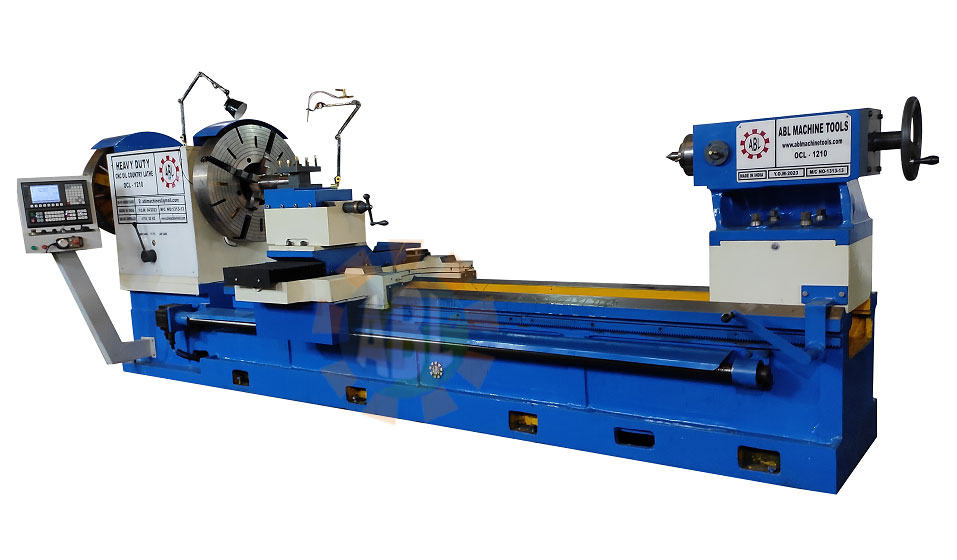

Horizontal Lathes – Semi CNC Type

TURNING / THREADING / TAPER TURNING & THREADING

SEMI-CNC Horizontal Lathe Machine, is an ECONOMICAL ALTERNATE to a CNC Lathe Machine. The Machine Chuck is Driven through a Geared Head powered by induction motor, having variable Spindle Speeds through Variable Frequency Variable Voltage Drive. The Saddle Unit is controlled with the AC Servo Motor & the CNC Controller synchronized with the machine chuck to ensure perfection to achieve the desired program (job). Motorized Tool Post & Tail Stock can also be provided as an option.

Product Specifications

| MODEL | ABL-SC-2M | ABL-SC-3M | ABL-SC-5M |

|---|---|---|---|

| CAPACITY | |||

| ADMIT BETWEEN CENTERS | 2000 MM | 3000 MM | 5000 MM |

| CENTER HEIGHT | 400 MM | 450 MM | 500 MM |

| BED WIDTH | 600 MM | 650 MM | 750 MM |

| SWING OVER BED | 800 MM | 900 MM | 1000 MM |

| SWING OVER CROSS SADDLE | 400 MM | 500 MM | 600 MM |

| HEAD STOCK | |||

| SPINDLE BORE | 60 MM / 80 MM | 80 MM / 100 MM | 100 MM |

| NO. OF SPINDLE SPEEDS | STEPLESS | STEPLESS | STEPLESS |

| RANGE OF SPINDLE SPEEDS | 30-600 RPM | 15-400 RPM | 15-300 RPM |

| MAIN SPINDLE TAPER | MT-4 | MT-5 | MT-6 |

| 4 JAW – INDEPENDENT MANUAL CHUCK | 400 M | 500 MM | 600 MM |

| TAIL STOCK | |||

| TAIL STOCK QUILL DIAMETER | 100 MM | 150 MM | 200 MM |

| TAIL STOCK QUILL TRAVEL | 200 MM | 250 MM | 300 MM |

| TAIL STOCK QUILL TAPER | MT-4 | MT-5 | MT-5 |

| SLIDE & CARRIAGE | |||

| CROSS SLIDE TRAVEL | 400 MM | 500 MM | 600 MM |

| TOOL SIZE | 25 X 25 MM | 25 X 25 MM | 32 X 32 MM |

| MOTOR POWER | |||

| MAIN SPINDLE DRIVE POWER (INDUCTION MOTOR) | 10 HP | 15 HP | 20 HP |

| LONGITUDINAL FEED POWER (AC SERVO MOTOR) | 12 NM | 20 NM | 20 NM |

| CROSS FEED POWER (AC SERVO MOTOR) | 12 NM | 20 NM | 20 NM |

| COOLANT PUMP MOTOR | 0.1 HP | 0.1 HP | 0.1 HP |

Standard Accessories

- Automatic 4 Station Turret

- CNC Controller – FANUC/SIEMENS

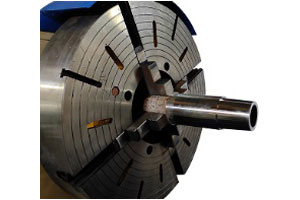

- 4 Jaw – Manual Chuck (Front)

- Electrical Panel & Accessories

- Steady Rest & Follow Rest

- Chuck Guard

- Foundation Bolt Kit

- Instruction & Maintenance Manual

Optional Accessories

- 4 Jaw Chuck (Back End)

- Motorized Tail Stock

- Chip Conveyor System

- Machine Body Enclosure

- 2 Years Normal

- Maintenance Spare Set

Salient Features

- Auto Threading Feature with AC Servo Feed Motors for Longitudinal & Cross Feeds through CNC Controller

- Most suitable for a widest range of Threading Options, API Threading, Taper Turning & Threading Options, Turning, Cutting, Facing etc.

- Graded Machine Castings complying to the IS/Equiv. Standards

- Heavily Ribbed Bed Construction, Hardened & Internally Ground Gear Teeth Lapped

- Induction Hardened Bed Guide way from Long Life

Video Gallery

Image Gallery

CNC Controller

Heavy Chuck

Double End Chuck Option

Heavy Lathe Bed Structure