Capstan Lathes

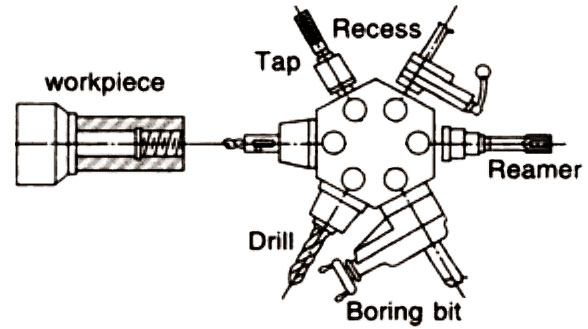

BATCH PRODUCTION/SMALL COMPONENTS/TURNING, DRILLING, GROOVING,THREADING, BORING, RECESSING, FORMING ETC

Capstan Lathes, suitable for batch production of small components & secondary operations requiring Turning, Drilling, Grooving, Threading, Boring, Recessing, Forming.

Product Specifications

| MODELS | C 20 | C 25 | C 25G | C 32 | C 40 | C 40G | C 50 | C 60 |

|---|---|---|---|---|---|---|---|---|

| Spindle Hollow | 25 | 28 | 32 | 38 | 42 | 42 | 52 | 62 |

| Max. Collect Cap. | 20 | 25 | 25 | 32 | 40 | 40 | 50 | 60 |

| Range of Spindle Speeds [RPM] | 650-1600 | 650-1600 | 275-900 | 165-1500 | 165-1500 | 100-1050 | 100-1050 | 90-1000 |

| Max. Dist. Spindle Nose to Turret Face | 300 | 375 | 400 | 425 | 425 | 430 | 430 | 430 |

| CROSS SLIDE TRANSVERSE TRAVEL | 95 | 95 | 95 | 95 | 95 | 150 | 150 | 150 |

| CROSS SLIDE LONGITUDINAL TRAVEL | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Length of Bed | 980 | 1050 | 1275 | 1225 | 1225 | 1375 | 1375 | 1375 |

| Width of Bed | 178 | 178 | 178 | 178 | 178 | 230 | 230 | 230 |

| Center Height | 165 | 165 | 165 | 165 | 165 | 190 | 190 | 190 |

Standard Accessories

- Manual Turret

- Cross Slide with 2 Tool Posts

- 1 No. Coupling

- Elec. Motors

- Spanner Set

- Allen Key Sets

- Oil Cans

- Instruction Manual

Optional Accessories

- Collet Chuck

- Bar Feed Attachment

- Vertical Slide

- Coolant Pump

- Feed for Turret Slide

- Extra Collets

Video Gallery

Image Gallery

Various Operations in a Single Set-Up Productive + Convenient!