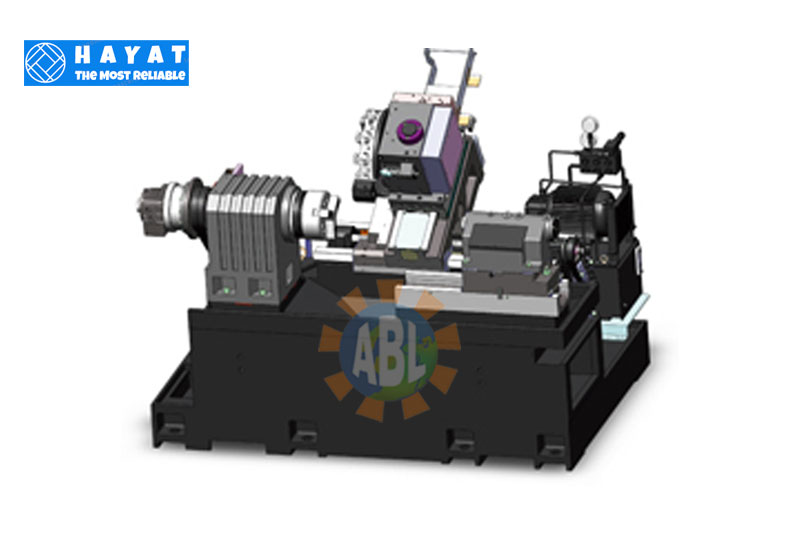

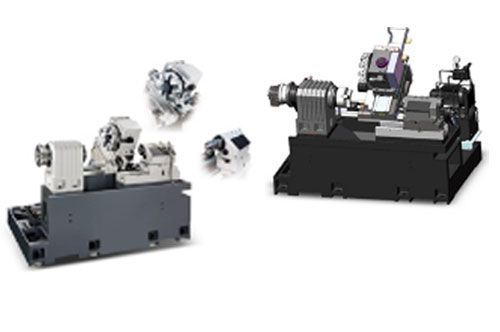

CNC, Precision Lathe Machine

CNC Precision Lathe Machines Manufacturers in India

CNC Lathe Machine is “HAYAT” series of ABL which means “life”. It truly adds life to the workshop. The machine ensures best accuracy with low maintenance.

Product Specifications

| MODEL | DESCRIPTION | SBL-500 | SBL-500 | SBL-800 |

|---|---|---|---|---|

CAPACITY | Swing Over Bed | Ø450 | Ø450 | Ø 600 |

| Swing Over Saddle | Ø375 | Ø375 | Ø 390 | |

| Max. Turning Diameter | Ø290 | Ø250 | Ø 410 | |

| Max. Working Length | 500 | 435 | 700 | |

| Distance Between Centres | 600 | 600 | 800 | |

| Bar Capacity | Ø52 | Ø65 | Ø75 | |

| Chuck Size | 200 | 250 | 250 | |

| STROKE | X-Axis Stroke | 165(145+20) | 190 (125+65) | 250(210+40) |

| Z-Axis Stroke | 520 | 460 | 750 | |

| FEED RATE | Axial Rapid Feed Rate (m/min) | X:20, Z:25 | X:20, Z:25 | X:20, Z:25 |

| Cutting Feed Rate (X/Z) mm/min | 10000 | 10000 | 10000 | |

| SPINDLE | Spindle Speed (rpm) | 3000 | 3000 | 3000 |

| Spindle Nose | A2-6 | A2-6 | A2-8 | |

| Spindle Bore Diameter | Ø66 | Ø76 | Ø88 | |

TURRET | Turret Type & Storage Capacity | Hyd. V8 (opt. V12) | VDI 30 / V 12 | Hyd. V8 (opt. V12) |

| Square Tool Dimension | 25×25 | 20 x 20 | 25×25 | |

| Boring Tool Dimension | Ø40 | Ø32 | Ø40 | |

| MOTOR | Spindle Motor Output (HP) | 14.7/20 | 14.7/20 | 14.7 / 20 |

| Axial Servo Motor Output (HP) | X:2.4, Z:2.4 | X: 4, Z: 4 | X:4.0, Z:4.0 |

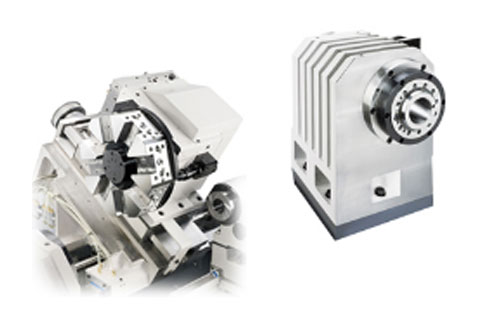

Standard Accessories

- CNC Controllers-FANUC / Siemens / Mitsubishi

- Hollow Hydraulic 3-jaw Chuck

- Hydraulic V8 Turret/VDI Power

- Turret

- Hydraulic Tailstock

- Foot Switch Control for Chuck

- Coolant System

- Automatic Lubrication System

- 3-color Warning Lamp

- Working Lamp

- Tool Box with Tools

- Chip Conveyor & Chip Cart

- Operation Manual

- Maintenance Manual

- Auto Power OFF

- Dynamic Graph Simulation

- Rigid Tapping

- Rigid Tapping

- RS-232 Interface

- Memory Card Interface (PCMCIA)

- Ethernet

Optional Accessories

- Spindle Speed 4200 rpm

- V12 Hydraulic Turret

- V8/V12 Servo Turret

- Programmable Tailstock

- Air Blast Device

- Parts Catcher

- Product Conveyor

- Auto Door

- Oil Mist Collector

- Bar Feeder Interface

- Oil Skimmer

- Manual/Auto Tool Presetter

- Automatic Loading/Unloading Device

- Robot

Salient Features

- Optimal Structure Design

- Ruggedly Constructed Head Stock

- Box Ways on X & Z Axis

- Box Ways on X & Z Axis

- High Speed Precision Turret

- Rigid & Robust Tail Stock

- Oil Fluid Separation Tank

- Controllers - FANUC / Siemens / Mitsubishi

Video Gallery

Image Gallery

ENQUIRE NOW

Wide Range of CNC Precision Lathe Machines

In modern industrial manufacturing, precision and consistency are key factors that determine productivity and quality. CNC Precision Lathe Machines have become an essential tool for manufacturers who require exacting tolerances, repeatable performance, and high efficiency. As a leading CNC Precision Lathe Machine manufacturer in India, ABL Machine Tools offers state-of-the-art machines designed to deliver superior performance across a range of industries.

A CNC precision lathe is designed to perform high-accuracy turning operations on various materials, including metals, alloys, and plastics. Equipped with advanced Computer Numerical Control (CNC) systems, these machines automate complex machining tasks, reduce human error, and enhance production speed while maintaining exact dimensional precision.

ABL Machine Tools manufactures a wide range of CNC precision lathes that cater to both small-scale and large-scale production requirements. These machines are engineered with rigid bed construction, high-quality spindles, precision lead screws, and advanced servo motors to achieve smooth, accurate, and consistent machining results. Industries such as aerospace, automotive, defense, medical device manufacturing, and general engineering benefit from the reliability and performance of these machines.

One of the hallmarks of ABL Machine Tools is its ability to provide customized solutions. Every manufacturing process is unique, and ABL specializes in designing custom-made CNC precision lathe machines tailored to client-specific requirements, including workpiece size, spindle speed, automation features, and CNC control specifications. This ensures maximum efficiency, reduced cycle times, and high-quality output for even the most complex components.

ABL’s CNC precision lathes are not only trusted in India but also internationally, with exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt. These machines are renowned for their durability, precision, and long-term performance under demanding industrial conditions.

Key Advantages of ABL CNC Precision Lathe Machines:

- High precision and repeatability for complex turning tasks

- Automation for increased productivity and reduced human error

- Versatile applications across multiple industries

- Custom-built solutions to meet specific production requirements

- Robust construction for long-lasting reliability and low maintenance

CNC, Precision Lathe Machines Manufacturers in Saudi Arabia, CNC, Precision Lathe Machines Manufacturers in UAE, CNC, Precision Lathe Machines Manufacturers in Qatar, CNC, Precision Lathe Machines Manufacturers in Kuwait, CNC, Precision Lathe Machines Manufacturers in Bahrain, CNC, Precision Lathe Machines Manufacturers in Oman, CNC, Precision Lathe Machines Manufacturers in Egypt

FAQ – CNC Precision Lathe Machines

What is a CNC Precision Lathe Machine?

A CNC Heavy Duty VTL is a precision machine tool designed to turn large and heavy workpieces placed vertically. It uses Computer Numerical Control (CNC) for automated operations, ensuring high accuracy and repeatability.

What industries use CNC precision lathes?

These machines are widely used in:

- Aerospace (engine components, turbine parts)

- Automotive (large gears, brake drums, wheels)

- Oil & gas (valves, flanges, drilling equipment)

- Power & energy (turbine housings, generator parts)

- Heavy engineering and shipbuilding

What are the advantages of CNC Precision Lathe Machines?

A vertical turning lathe provides superior stability and support for large-diameter or heavy workpieces that are difficult to mount horizontally. It also offers better weight distribution, making machining safer and more precise.

Can CNC Precision Lathe Machines be customized?

- High accuracy with CNC automation

- Ability to handle oversized and heavy components

- Reduced setup time and improved productivity

- Suitable for both roughing and finishing operations

- Customization options for specific applications

Why choose Indian manufacturers for CNC precision lathes?

Yes. ABL Machine Tools specializes in custom-made CNC Heavy Duty VTLs tailored to production needs—covering bed size, spindle power, automation features, and CNC control systems.

How does a CNC Precision Lathe differ from a conventional lathe?

Absolutely. Indian manufacturers like ABL Machine Tools are globally trusted for robust, cost-effective, and technologically advanced VTL machines. Their exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt highlight their international quality standards.

What maintenance is required for CNC Precision Lathe Machines?

Regular lubrication, spindle and chuck inspections, CNC system monitoring, and alignment checks are essential. Preventive maintenance ensures maximum uptime and long-term reliability.

Does ABL Machine Tools provide after-sales support?

Yes. ABL Machine Tools provides full after-sales support, including operator training, spare parts supply, technical assistance, and long-term service agreements.