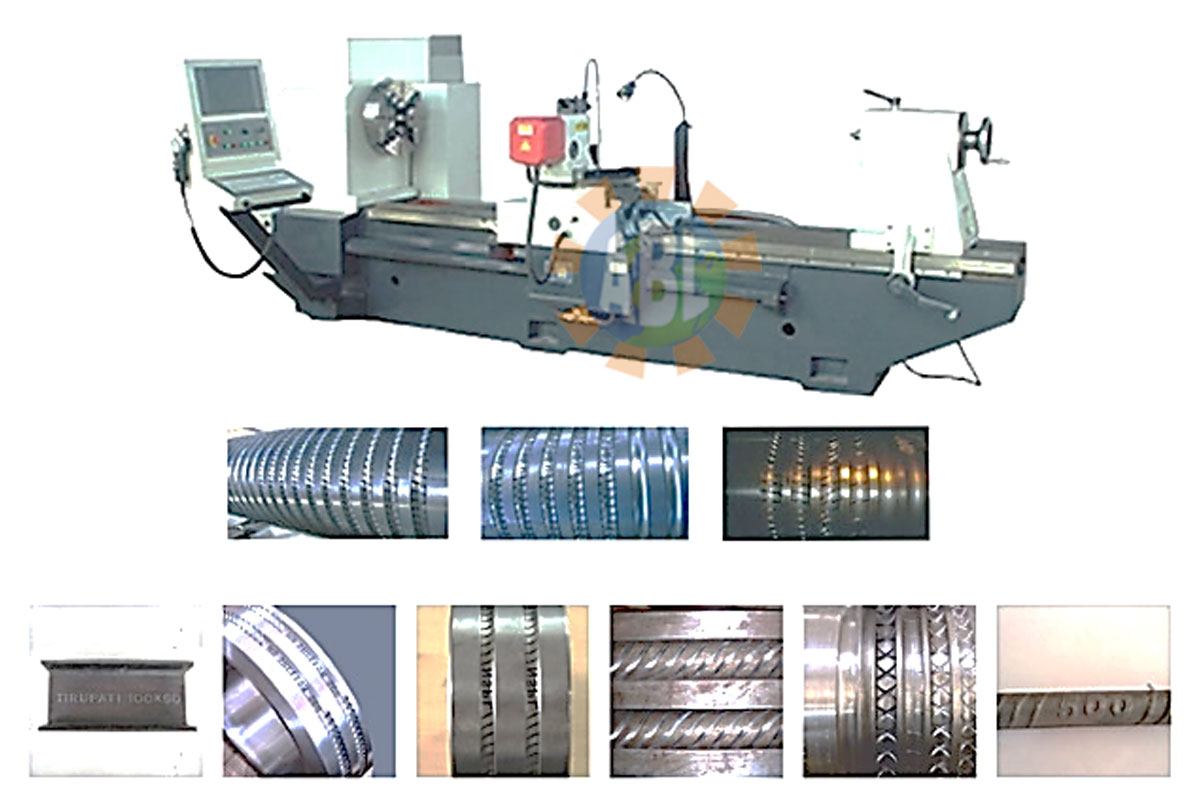

CNC, Roll Notching & Marking Lathe

STEEL MILL ROLL NOTHCING & MARKING / CNC CONTROLLER / CONVENIENT USE

CNC Roll Notching & Marking Lathe Machines Manufacturers in India

CNC Steel Mill Roll, Notching & Branding Lathe, is the must machine for all steel mills. This Lathe Machine very conveniently notches & create programmed marking on the chilled steel rolls. Machine can handle all international Standards Rolled Ribbed Bars like ISO6935-2, JIS G3112, ASTM A615, BS 4449, BS4461, GB1499.2-2007, ANSI etc as well as can produce real “JIS” & International Standard Notches.

Product Specifications

| MODEL | ABL-NB25 |

|---|---|

| Diameter of the Processed Roller | 100 to 560 MM |

| Length of the Processed Roller | 800 to 2500 MM |

| Max. Roll Weight | 1000 KG |

| Notching Range for Re-Bar Diameter | 6 MM – 50 MM |

| Workpiece Swivel Speed | 0-32 RPM |

| Cutting Type | Fly Cutter Head |

| Cutter Spindle Speed | 0 to 500 RPM |

| Name Marking Device | Milling Head Swivel Cutting |

| Cutter Spindle Speed | 30 to 2000 RPM |

| Head Stock Spindle Bore | MT 5 |

| Head Stock, 4 Jaw Independent Chuck Diameter | 400 MM |

| CNC 4 Axis Controller System | Siemens 828D |

| Motors & Drives | AC Servo Motor |

| Overall Machine Dimensions (L x W x H) | 4000 x 1500 x 1900 MM |

| Approx. Machine Weight | 5500 KGS |

Standard Accessories

- CNC Controllers & Drives

- Elec. Control Panel

- Elec. Control Pendent

- Foundation Bolt Kit

- Machine Lighting

Optional Accessories

- Cutting Tool Sharpening Grinder

- Air Conditioner for Elec. Cabinet

- Extra Set of 4 Jaw Chuck 400 MM

- 3 Jaw Self Centering Chuck 400 MM

- 2 Years Normal Maintenance Spares

Salient Features

- Designed to Get Swivel Function and Fly Cutting Function in One Unit.

- Suitable for Casting Rolls and Tungsten Carbide Roll Rings.

- Sturdy and rigid machine construction.

- One Machine for Two Jobs : Roll Notching & Name Marking.

- Fully Automatic Notching from First Grove to Last Groove.

- Equipped With 'Siemens' High Performance 4-Axis CNC System.

- System Can Continue Job from Pause After Tool Changed During Process.

- High Precision Ball Screw to Ensure Precision Transmission for Longitudinal.

- Precision Rolling Arc Guide-Way Provide Swivel Head with Fine Position Support.

- Notching on One groove can be done is about 15 - 20 Minutes.

- Name Marking on One groove can be done is about 10 Minutes.

Video Gallery

Image Gallery

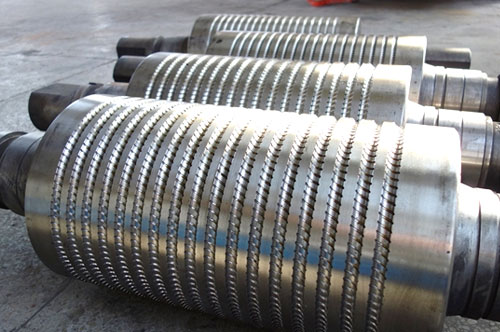

Finished Notched & Marked Rolls

Machines Under Production

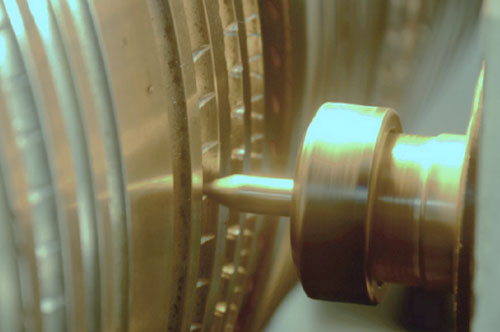

Operational View

ENQUIRE NOW

Wide Range of CNC Roll Notching & Marking Lathe Machines

In modern industrial production, precision, efficiency, and automation are critical for meeting high-quality standards. CNC Roll Notching & Marking Lathe Machines are specialized equipment designed to perform notching, marking, and turning operations with exceptional accuracy. Among the leading manufacturers in India, ABL Machine Tools delivers robust, high-performance CNC roll notching and marking lathes that cater to diverse industrial requirements.

CNC roll notching and marking machines are primarily used for creating precise notches, grooves, or marks on cylindrical and sheet metal components. These machines are widely applied in industries such as pipe and tube fabrication, automotive, shipbuilding, heavy engineering, and structural steel manufacturing. By integrating CNC technology, these machines ensure consistent precision, automated operations, and minimal human error, which is essential for producing high-quality components in bulk production.

ABL Machine Tools offers a wide range of CNC roll notching and marking lathe machines engineered for durability and performance. These machines feature rigid bed construction, advanced servo motors, high-torque spindles, and user-friendly CNC interfaces. This combination allows operators to perform complex notching, marking, and turning operations on metal pipes, tubes, rods, and bars with exceptional precision.

One of the standout features of ABL Machine Tools is its ability to provide custom-built solutions. Each machine can be tailored to meet specific production needs, including workpiece size, notch dimensions, marking patterns, CNC control systems, and automation features. This ensures that manufacturers achieve maximum productivity, minimal material wastage, and consistent output quality.

With a strong international presence, ABL Machine Tools exports its CNC roll notching and marking machines to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, making it a trusted global supplier. Their machines are recognized for long-term durability, operational efficiency, and precision, even under demanding industrial conditions.

Key Advantages of ABL CNC Roll Notching & Marking Machines:

- High-precision notching and marking for metal pipes, rods, and tubes

- Automated CNC operations for repeatable and error-free performance

- Customizable features to suit specific industrial applications

- Robust construction for long-lasting reliability

- Comprehensive after-sales support including training, maintenance, and spare parts

CNC, Roll Notching & Marking Lathe Machines Manufacturers in Saudi Arabia, CNC, Roll Notching & Marking Lathe Machines Manufacturers in UAE, CNC, Roll Notching & Marking Lathe Machines Manufacturers in Qatar, CNC, Roll Notching & Marking Lathe Machines Manufacturers in Kuwait, CNC, Roll Notching & Marking Lathe Machines Manufacturers in Bahrain, CNC, Roll Notching & Marking Lathe Machines Manufacturers in Oman, CNC, Roll Notching & Marking Lathe Machines Manufacturers in Egypt

FAQ – CNC Roll Notching & Marking Lathe Machines

What is a CNC Roll Notching & Marking Lathe Machine?

A CNC Roll Notching & Marking Lathe Machine is a specialized lathe designed to perform precise notching, marking, and turning operations on cylindrical and sheet metal components using Computer Numerical Control (CNC) technology.

What industries use these machines?

These machines are commonly used in:

- Pipe and tube fabrication

- Automotive component manufacturing

- Shipbuilding and heavy engineering

- Structural steel fabrication

- Industrial equipment production

What are the benefits of CNC Roll Notching & Marking Machines?

- High precision and repeatability for notching and marking tasks

- Automated operations reduce human error and labor costs

- Ability to handle a variety of materials including metal tubes, rods, and bars

- Consistent quality for large-scale production

- Customizable for specific industrial requirements

Can CNC Roll Notching & Marking Machines be customized?

Yes. ABL Machine Tools provides custom-built machines with options for workpiece size, notch dimensions, marking patterns, CNC control systems, and automation features to meet specific production goals.

How do these machines differ from conventional lathes?

Unlike conventional lathes, CNC Roll Notching & Marking Machines automate notching and marking processes, provide higher precision, allow repeatable operations, and reduce manual intervention, making them ideal for high-volume and complex production tasks.

Why choose Indian manufacturers for CNC Roll Notching & Marking Machines?

Indian manufacturers like ABL Machine Tools are globally recognized for producing durable, precise, and cost-effective machines. Their exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt demonstrate international trust in quality and performance.

What maintenance is required for CNC Roll Notching & Marking Machines?

Regular maintenance includes lubrication of moving parts, inspection of CNC systems, alignment checks, and cleaning of the work area. Preventive maintenance ensures long-term reliability and optimal performance.

Does ABL Machine Tools provide after-sales support?

Yes. ABL Machine Tools offers comprehensive after-sales support, including operator training, spare parts supply, technical assistance, and maintenance services to ensure smooth and efficient operation.