CNC, Surface Grinding Machine

CNC Surface Grinding Machine Manufacturers in India

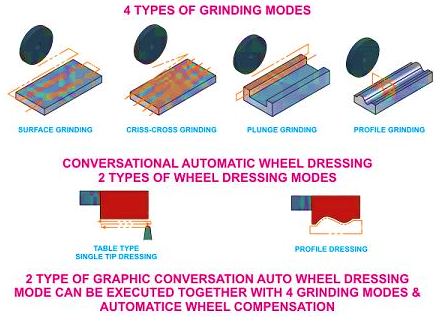

CNC Surface Grinding Machine, suitable for multiple grinding modes with CNC Controllers.

Precision, accuracy, and efficiency are the hallmarks of modern manufacturing, and CNC Surface Grinding Machines play a pivotal role in achieving these standards. As one of the leading CNC Surface Grinding Machine manufacturers in India, ABL Machine Tools offers high-performance machines that cater to the needs of diverse industries requiring exacting surface finishes and dimensional accuracy.

Product Specifications

| MODELS [CNC – JUMBO Series] | JSG-3075 | JSG-30100 | JSG-4080 | JSG-40100 | JSG-30150 |

|---|---|---|---|---|---|

| Max. Table Size | 300x 750 | 300 x 1000 | 400 x 800 | 400 x 1000 | 300 x 1500 |

| Max. Longitudinal Travel | 850 | 1075 | 875 | 1100 | 1575 |

| Max. Cross Transverse | 350 | 350 | 450 | 450 | 350 |

| Max. Spindle Centre Height above Table | 550 | ||||

| Max. Table Speeds (m/min) | 18 | ||||

| Power Cross Transverse (mm/min) | 3000 | ||||

| Auto Cross Feed at each Table Reversal (Infinitely variable) | Programmable | ||||

| Least Count of Vertical feed head wheel | 0.001 | ||||

| Control (2 AXIS) optional | HUST/Siemens | ||||

| Programming | Standard ‘G’ code and ‘M’ code, With NC File | ||||

| Size of Grinding Wheel | 350 x 50 x 127 | ||||

| Power of Spindle Motor (HP) | 5 | ||||

| Speed of Grinding Spindle (RPM) | 1400 | ||||

| Working Pressure (Kg/CM) | 20 | ||||

| Motor (HP) | 3 | ||||

| Tank Capacity (Ltr) | 125 | ||||

| Rapid Traverse (mm/min) | 3000 | ||||

| Min. programmable increment | 0.001 | ||||

| Automatic intermittent feed each table stroke | Programmable | ||||

| Stroke | 350 | 350 | 450 | 450 | 350 |

| Continuous feed rate (m/mm) | 0.5 to 1000 | ||||

| Rapid traverse (mm/min) | 3000 | ||||

| Min. programmable increment | 0.001 | ||||

| Automatic intermittent feed each table stroke | Programmable | ||||

| Max. Longitudinal traverse | 825 | 1075 | 875 | 1075 | 1575 |

| Infinitely variable speed (m/min) | 1.5-18 | ||||

| Hydraulic Motor Power (HP) | 3 | ||||

Max. weight of the job With chuck Without chuck |

150 | ||||

| X-Axis | With L.M Guide, Ball screw, and Servo Motor | ||||

| Z-Axis | With L.M Guide, Ball screw, and Servo Motor | ||||

| Repeatability for 6 consecutive readings | 0.002 | ||||

| Total connected power (approx.) KW | 7.5 | 7.5 | 10 | 10 | 10 |

Salient Features

- State-of-the-art grinder ideally suited for tool room and production applications

- Suitable for precision grinding and material removal in short time

- Large clamping area to meet the requirements of majority of applications

- The compound table version adopted is the most popular concept in this category of machines

- Wheel spindle supported on large diameter angular contact ball bearings

- Wheel head slide movement and transverse movement of compound table on preloaded, antifriction, linear recirculation roller bearings

- X & Z axes driven by directly coupled digital AC servomotors

- Y-Axis ball screw coupled to digital AC servomotor through gear box

- Dressing by means of table mounted dresser or retraction type of dresser mounted on table

- Centralised lubrication

Video Gallery

ENQUIRE NOW

Wide Range of CNC Surface Grinding Machines

CNC surface grinding machines are designed to provide flat, smooth, and highly precise surfaces on metal and non-metal workpieces. Utilizing Computer Numerical Control (CNC) technology, these machines automate grinding operations, ensuring consistent precision, reduced manual intervention, and improved efficiency. They are widely used for dies, molds, machine components, precision tools, and aerospace parts, where exact surface tolerances are critical.

ABL Machine Tools manufactures a comprehensive range of CNC surface grinding machines equipped with advanced features such as rigid bed construction, high-speed grinding spindles, digital readouts, and user-friendly CNC controls. These machines are engineered to deliver accurate, repeatable, and smooth finishes on a variety of materials including steel, aluminum, brass, and hardened alloys. Their robust construction ensures stability, minimal vibration, and long-term operational reliability.

A key advantage of ABL Machine Tools lies in its ability to provide customized CNC surface grinding machines. Every production requirement is unique, and ABL designs machines tailored to specific needs, including table size, grinding capacity, spindle speed, automation features, and CNC control specifications. This customization enables manufacturers to achieve maximum productivity, precise surface finishes, and reduced material wastage.

With a strong global presence, ABL Machine Tools exports its CNC surface grinding machines to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, earning a reputation for durability, precision, and reliability in international markets. Each machine undergoes strict quality control checks to ensure it meets international standards and provides long-lasting performance even under demanding industrial conditions.

Key Benefits of ABL CNC Surface Grinding Machines:

- High-precision grinding with excellent surface finish

- Automated CNC operations for repeatable and consistent results

- Custom-built machines tailored to specific production requirements

- Robust design for stability, reduced vibration, and long service life

- Reliable after-sales support, including training, spare parts, and technical assistance

CNC, Surface Grinding Machine Manufacturers in Saudi Arabia, CNC, Surface Grinding Machine Manufacturers in UAE, CNC, Surface Grinding Machine Manufacturers in Qatar, CNC, Surface Grinding Machine Manufacturers in Kuwait, CNC, Surface Grinding Machine Manufacturers in Bahrain, CNC, Surface Grinding Machine Manufacturers in Oman, CNC, Surface Grinding Machine Manufacturers in Egypt

FAQ – CNC Surface Grinding Machines

What is a CNC Surface Grinding Machine?

A CNC Surface Grinding Machine is a precision machine tool that uses Computer Numerical Control (CNC) technology to grind flat or contoured surfaces on metal and non-metal workpieces with high accuracy and repeatability.

What are the main applications of CNC surface grinding machines?

These machines are widely used in:

- Die and mold manufacturing

- Aerospace and automotive component production

- Precision tool and instrument manufacturing

- Machine component finishing

- Metalworking and fabrication industries

What are the advantages of CNC Surface Grinding Machines?

- High precision and repeatable surface finish

- Automated operations reduce human error

- Ability to handle various materials including steel, aluminum, and alloys

- Consistent quality for large production runs

- Customizable features for specific industrial requirements

Can CNC Surface Grinding Machines be customized?

Yes. ABL Machine Tools provides custom-built CNC surface grinding machines with options for table size, grinding capacity, spindle speed, automation, and CNC control systems to meet unique production goals.

How does a CNC surface grinder differ from conventional grinders?

Unlike conventional grinders, CNC surface grinders automate the grinding process, ensuring higher precision, consistent results, and reduced operator intervention, which is crucial for high-volume or complex manufacturing.

Why choose Indian manufacturers for CNC Surface Grinding Machines?

Indian manufacturers like ABL Machine Tools are recognized globally for producing durable, precise, and cost-effective machines, with exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt.

What maintenance is required for CNC Surface Grinding Machines?

Routine maintenance includes lubrication of moving parts, inspection of spindles and bearings, checking CNC controls, and cleaning the work area. Regular preventive maintenance ensures long-term reliability and performance.

Does ABL Machine Tools provide after-sales support?

Yes. ABL Machine Tools offers comprehensive after-sales support, including operator training, spare parts supply, technical assistance, and maintenance services to ensure smooth and efficient operation.