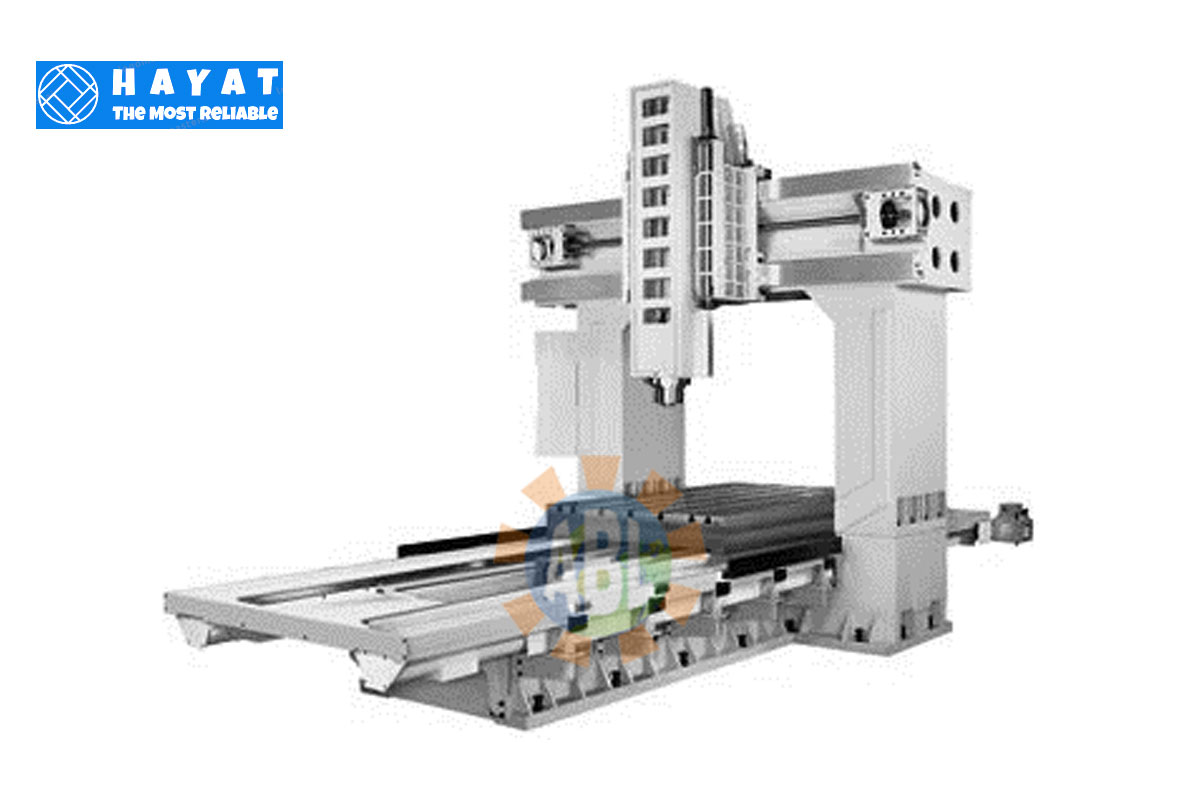

Gantry Type, CNC Vertical Machining Center

GIANT SERIES / GANTRY TYPE /HEAVY MACHINE STRUCTURE

Gantry Type CNC Vertical Machining Center Manufacturers in India

Heavy Duty, CNC Vertical Machining Center was designed specifically for large part machining & that too with ease of operation. This machine is used for the production of moulds and dies for various industries such as automobiles, oil refinery, power generator, casting foundries and so on.

In the era of precision engineering and large-scale production, industries demand machine tools that combine accuracy, strength, and flexibility. The Gantry Type CNC Vertical Machining Center (VMC) stands out as a powerful solution for machining large and heavy components with high efficiency. As one of the leading Gantry Type CNC Vertical Machining Center manufacturers in India, ABL Machine Tools is committed to delivering advanced machines that meet global manufacturing standards.

Product Specifications

| MODEL | DMC-2010 | DMC-2514 | DMC-3020 | DMC-4025 |

|---|---|---|---|---|

| TABLE | ||||

| Table size | 2000×1100 | 2500x1400x1300 | 3000x2000x1500 | 4000x2500x2000 |

| T-slot size | 9x18x125 | 10x18x125 | 12x22x160 | 16×22/28×250 |

| Dist. From Floor to Table | 920 | 920 | 920 | 920 |

| Max. Load on Table (Kg) | 5000 | 6000 | 10000 | 15000 |

| Distance Between Column | 1400 | 1600 | 1800/2300 | 3000/3300 |

| CAPACITY | ||||

| X-Axis Travel | 2200 | 2700 | 3200 | 4200 |

| Y-Axis Travel | 1300 | 1500 | 1700/2200 | 2900/3200 |

| Z-Axis Travel | 600 | 800/920 | 800/920 | 920/1100 |

| Dist. From Spindel Face to Table Top (min.) | 200 | 200 | 200 | 200 |

| Rapid Traverse(x/y/z) – m/min | 20/20/15 | 20/20/15 | 15/15/15 | 15/15/15 |

| Cutting Feed Rate – m/min | 10 | 10 | 10 | 10 |

| MAIN SPINDLE | ||||

| Spindle Speeds (rpm) | 10000 | 6000 | 6000 | 4000/6000 |

| Power (kw) | 22/26 | 22/26 | 22/26 | 22/26 |

| Spindle Taper | BT-40/BT-50 | BT-50 | BT-50 | BT-50 |

| AUTOMATIC TOOL | ||||

| No. of Tools | 20/24 | 24 | 24 | 24 |

| Tool Dia. Max. (All Full-Adj. Empty) | 90-125/125-250 | 125-250 | 125-250 | 125-250 |

| Tool Length Max. | 300/350 | 350 | 350 | 350 |

| ACCURACY | ||||

| Positional Accuracy/300 | + 0.015 | + 0.015 | + 0.015 | + 0.015 |

| Repeatability | + 0.006 | + 0.006 | + 0.010 | + 0.010 |

| Approx. Net Weight (Kg) | 20000 | 28000 | 36000 | 58000 |

Standard Accessories

- AC Spindle Drive

- AC Servo Axis Drive

- L.M. Roller type Guideways

- Chip Conveyor

- Auto & Manual Collet

- Centralized & Programmer Lubrication

- Electricals with Quality Device &

- Work Light

- CNC SIEMENS SINUMERIK 828D

Optional Accessories

- Laser Calibrated axis for high precise positing accuracy & Repeatability

- Linear Glass Scale for Axes

- Collet Through Spindle

- ATC (32/40/60/90)

- Oil Mist Collector System

- Auto Indexing Head (Horizontal)

- Manual Horizontal Head

- Rotary Table

- Tool Probe

- Job Probe

- Gear-Box (4000rpm)

- Full Cover Enclosures

Salient Features

- Our high-density castings are heavier with less webbing. This means less harmonics and less thermal variation

- Heavy duty transmissions, which are standard on larger models, allow stock removal at high spindle speeds.

- All geometric accuracies confirming to national & intl. standards.

Video Gallery

Image Gallery

ENQUIRE NOW

Wide Range of Gantry Type CNC Vertical Machining Centers

ABL Machine Tools designs and manufactures Gantry Type CNC VMCs that are trusted not only across India but also in Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt. Known for their heavy-duty construction and cutting-edge CNC control systems, these machines are ideal for industries such as aerospace, shipbuilding, automotive, energy, and heavy engineering.

The gantry structure provides exceptional rigidity and stability, making it possible to machine large workpieces with superior accuracy. Equipped with a vertical spindle, these machining centers allow for multi-axis operations including milling, drilling, tapping, and contouring. The advanced CNC programming ensures consistent performance, reduced cycle times, and high repeatability.

One of the major advantages of ABL’s Gantry Type CNC VMCs is their customization capability. Customers can choose from a wide range of configurations such as spindle speeds, table sizes, axis travels, tool changers, and automation features. This makes them suitable for both medium and large-scale production environments.

ABL Machine Tools focuses on durability and long-term reliability. Each Gantry Type CNC Vertical Machining Center is manufactured using high-quality components, precision engineering, and strict quality control measures. These machines are built to withstand heavy-duty operations while maintaining accuracy, ensuring long service life and low maintenance costs.

Along with advanced technology, ABL Machine Tools provides comprehensive after-sales support, including installation, operator training, preventive maintenance, and spare parts supply. This ensures clients receive end-to-end solutions for their manufacturing needs.

As industries worldwide move towards automation and smart machining, ABL Machine Tools continues to lead by offering custom-made Gantry Type CNC Vertical Machining Centers designed to match the unique production goals of each client. With a strong presence in both domestic and international markets, the company is recognized as a trusted partner for precision machining solutions.

For manufacturers seeking efficiency, scalability, and accuracy, ABL’s Gantry Type CNC Vertical Machining Centers provide the perfect blend of innovation and performance.

Gantry Type, CNC Vertical Machining Center Manufacturers in Saudi Arabia, Gantry Type, CNC Vertical Machining Center Manufacturers in UAE, Gantry Type, CNC Vertical Machining Center Manufacturers in Qatar, Gantry Type, CNC Vertical Machining Center Manufacturers in Kuwait, Gantry Type, CNC Vertical Machining Center Manufacturers in Bahrain, Gantry Type, CNC Vertical Machining Center Manufacturers in Oman, Gantry Type, CNC Vertical Machining Center Manufacturers in Egypt

FAQ – Gantry Type CNC Vertical Machining Center Machines

What is a Gantry Type CNC Vertical Machining Center?

A Gantry Type CNC VMC is a high-precision machine tool with a gantry-style structure designed to machine large and heavy components. It uses a vertically oriented spindle and CNC controls for multi-axis machining, ensuring accuracy and efficiency.

What are the main applications of Gantry CNC VMCs?

These machines are widely used in industries such as:

- Aerospace and defense

- Shipbuilding

- Energy and power equipment manufacturing

- Heavy engineering and automotive industries

- Large mold, die, and tooling production

What are the advantages of using Gantry Type CNC VMCs?

- High rigidity and stability due to the gantry structure

- Ability to handle large, heavy, and complex workpieces

- Precision machining with repeatability and consistency

- Multi-axis operations like milling, drilling, tapping, and contouring

- Customizable features to match production needs

How do Gantry CNC VMCs differ from standard VMCs?

Standard VMCs are ideal for small to medium-sized parts, while Gantry CNC VMCs are designed for large-scale and heavy-duty machining, offering greater table size, travel range, and load-bearing capacity.

Can Gantry CNC VMCs be customized?

Yes. ABL Machine Tools specializes in offering custom-built Gantry Type CNC Vertical Machining Centers, with options for spindle power, table size, axis travel, tool changer capacity, and automation to suit specific production goals.

Why choose ABL Machine Tools for Gantry CNC VMCs?

ABL Machine Tools is one of the leading Gantry Type CNC VMC manufacturers in India, supplying high-quality machines to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt. Their machines are known for durability, accuracy, and advanced CNC controls.

What maintenance is required for Gantry CNC VMCs?

Routine maintenance includes lubrication of moving parts, inspection of spindle alignment, checking ball screws, CNC system monitoring, and preventive servicing. Proper maintenance extends machine life and ensures reliable performance.

Does ABL Machine Tools provide after-sales service and training?

Yes. ABL Machine Tools provides installation support, operator training, spare parts, technical assistance, and regular maintenance services, ensuring maximum uptime and productivity for clients.