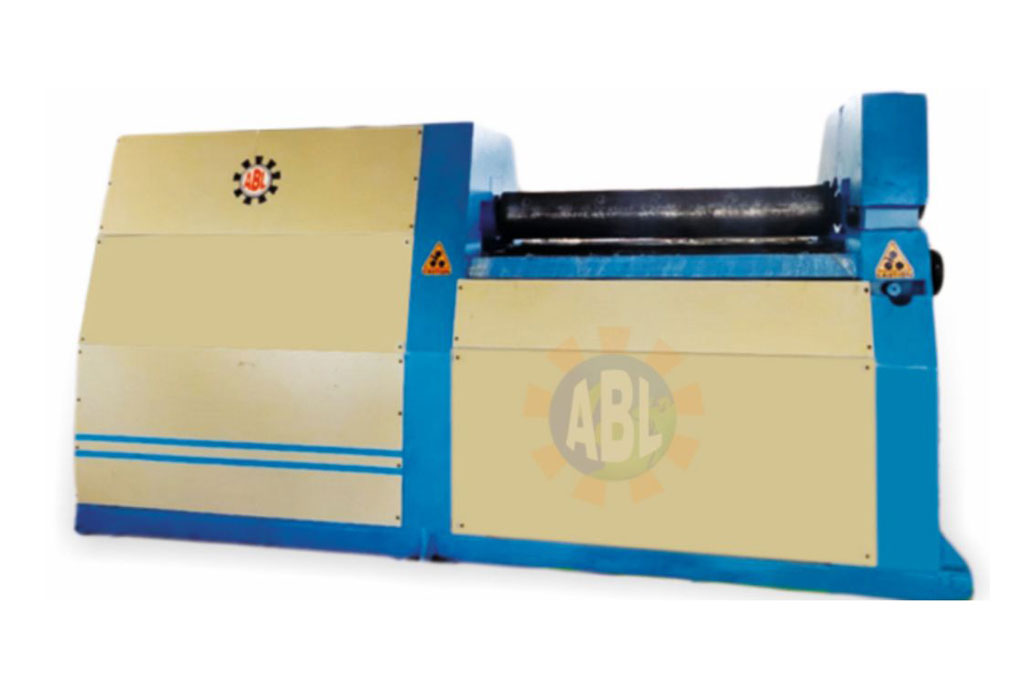

3 Roll Plate Rolling Machine

3 Roll Plate Rolling Machine Manufacturers in India

In the field of metal fabrication, 3 roll plate rolling machines are vital for bending and shaping metal plates into cylindrical or conical forms. Among the leading 3 roll plate rolling machine manufacturers in India, ABL Machine Tools stands out for its commitment to quality, precision, and innovation. With a strong presence in India, Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, ABL Machine Tools has become a trusted provider of high-performance rolling solutions for diverse industries.

Wide Range of 3 Roll Plate Rolling Machines

ABL Machine Tools manufactures a comprehensive range of 3 roll plate rolling machines suitable for various industrial applications. These machines are designed to handle metal plates of different thicknesses and sizes with high accuracy and smooth operation. Widely used in shipbuilding, pressure vessel manufacturing, steel fabrication, and heavy engineering industries, these machines ensure precise rolling and minimal material wastage.

Customized Solutions for Every Manufacturing Requirement

Understanding that every industry has unique production needs, ABL Machine Tools provides custom-made 3 roll plate rolling machines. Machines can be tailored according to plate thickness, rolling length, motor power, automation level, and control systems. This flexibility ensures that each machine perfectly aligns with client requirements, enhancing productivity, reducing downtime, and delivering consistent results.

Global Reach and Trusted Quality

ABL Machine Tools has built a reputation not only in India but also internationally. Its 3 roll plate rolling machines are exported to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, where they are valued for precision, durability, and long-term performance. Every machine is manufactured with high-grade materials and undergoes rigorous quality checks to ensure reliability in demanding industrial environments.

Why Choose ABL Machine Tools?

- Comprehensive range of 3 roll plate rolling machines for diverse applications.

- Custom-built solutions to match specific production goals.

- Global presence with satisfied clients in India and the Middle East.

- Focus on precision, durability, and operational efficiency.

- Reliable after-sales support including spare parts and technical assistance.

3 Roll Plate Rolling Machines Manufacturers in Saudi Arabia, 3 Roll Plate Rolling Machines Manufacturers in UAE, 3 Roll Plate Rolling Machines Manufacturers in Qatar, 3 Roll Plate Rolling Machines Manufacturers in Kuwait, 3 Roll Plate Rolling Machines Manufacturers in Bahrain, 3 Roll Plate Rolling Machines Manufacturers in Oman, 3 Roll Plate Rolling Machines Manufacturers in Egypt

FAQ – 3 Roll Plate Rolling Machines

What is a 3 roll plate rolling machine?

A 3 roll plate rolling machine is a metal forming tool used to bend flat metal plates into cylindrical or conical shapes. It uses three rollers—two fixed and one adjustable—to gradually shape the plate with precision.

What industries use 3 roll plate rolling machines?

These machines are widely used in:

- Shipbuilding and marine engineering

- Pressure vessel and boiler manufacturing

- Construction and infrastructure projects

- Heavy engineering and steel fabrication

- Oil & gas equipment manufacturing

What is the difference between a 2 roll, 3 roll, and 4 roll plate rolling machine?

- 2 Roll Machines – Used for thin sheet metal and simpler bends.

- 3 Roll Machines – Standard machines for medium to heavy plate rolling with versatility.

- 4 Roll Machines – Provide higher precision, easier pre-bending, and automation options.

What are the advantages of using a 3 roll plate rolling machine?

- High precision in bending metal plates

- Ability to roll various thicknesses and diameters

- Versatile for both cylindrical and conical shapes

- Cost-effective solution for medium to heavy fabrication needs

Can 3 roll plate rolling machines be customized?

Yes. ABL Machine Tools provides custom-built 3 roll plate rolling machines with options for plate thickness, rolling length, automation level, motor power, and digital control systems to match specific production requirements.

Why are Indian 3 roll plate rolling machines popular globally?

Manufacturers like ABL Machine Tools are trusted for durable, precise, and cost-effective machines. Their exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt demonstrate international reliability and high-quality engineering.

What maintenance is required for a 3 roll plate rolling machine?

Regular maintenance includes lubrication of rollers and bearings, inspection of hydraulic/electrical systems, checking alignment, and cleaning after use. Following the manufacturer’s service schedule ensures long-term performance.

Does ABL Machine Tools provide after-sales support?

Yes, ABL Machine Tools offers full after-sales support, including training, spare parts supply, and technical assistance to ensure smooth operation and maximum machine uptime.