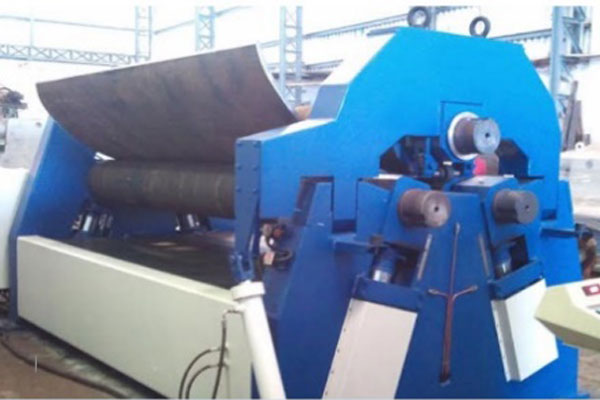

Hydraulic, Plate Rolling Machine (3 Roll Type)

3 ROLL TYPE / PYRAMID & PRE-PINCH TYPE / HYDRAULICALLY DRIVEN ROLLS

3 Rolls, Heavy Duty, Hydraulic Plate Rolling Machines produced by ABL are able to bend 60 mm to 100 mm in thickness and width of 1000 mm 5000 mm sheet metal materials in high quality and in an easy way. ABL machines have extremely strong bodies in view of welded St-52 steel construction body, roll shaft, bushes & bearings. The upper roll is rolling in a fixed position, the bottom rolls have adjustable movement for gripping, pinching & bending purposes.

Product Specifications

| Model | Working Length | Max. Bending Thickness | Max. Pre-Bending Thickness | Central Roll Ø | Side Roll Ø | Motor Capacity | Approx. Weight |

|---|---|---|---|---|---|---|---|

| UOM | MM | MM | MM | MM | MM | KW | KGS. |

| 3RH-2560 | 2550 | 60 | 45 | 450 | 420 | 52 | 23,200 |

| 3RH-2570 | 2550 | 70 | 55 | 500 | 460 | 73.5 | 30,500 |

| 3RH-2575 | 2550 | 75 | 60 | 550 | 500 | 73.5 | 42,500 |

| 3RH-2580 | 2550 | 80 | 65 | 580 | 480 | 74 | 58,000 |

| 3RH-2595 | 2550 | 95 | 75 | 620 | 560 | 169 | 63,000 |

| 3RH-25105 | 2550 | 105 | 85 | 680 | 600 | 180 | 73,000 |

| 3RH-3155 | 3100 | 55 | 40 | 450 | 420 | 52 | 25,000 |

| 3RH-3160 | 3100 | 60 | 45 | 500 | 460 | 73.5 | 33,000 |

| 3RH-3165 | 3100 | 65 | 50 | 550 | 500 | 73.5 | 45,000 |

| 3RH-3170 | 3100 | 70 | 60 | 580 | 480 | 74 | 60,000 |

| 3RH-3180 | 3100 | 80 | 65 | 620 | 560 | 169 | 65,000 |

| 3RH-3190 | 3100 | 90 | 75 | 680 | 600 | 180 | 73,000 |

| 3RH-4140 | 4100 | 40 | 25 | 450 | 420 | 52 | 26,800 |

| 3RH-4145 | 4100 | 45 | 30 | 500 | 460 | 73.5 | 35,500 |

| 3RH-4150 | 4100 | 50 | 35 | 550 | 500 | 73.5 | 47,600 |

| 3RH-4155 | 4100 | 55 | 45 | 580 | 480 | 74 | 65,000 |

| 3RH-4170 | 4100 | 70 | 55 | 620 | 560 | 169 | 69,000 |

| 3RH-4180 | 4100 | 80 | 65 | 680 | 600 | 180 | 75,000 |

Standard Accessories

- Hydraulically Driven Rolls

- Extra Heavy, Hydraulic Power Pack placed within machine body frame.

- Electrical Control Pendent

- Safety Guards

- Planetary Gear Boxes for Drive Rolls

- Centralized Lubrication System

- Hydraulic Side Door Dropper

- Foundation Bolt Kit

- Instruction & Maintenance Manual

Optional Accessories

- Pillar Jib Crane for Plate & Pipe Handling

- Digital Readout System

- Digital display for both side rollers

- Side and Central Support for big sheet metal diameters

- Extended rolls for Section Bending Caps/Dies

- Profile Rolls / Dies

- Material Feed Table

- Oil Cooling System

Salient Features

- Rigid Steel Body Structure

- Cone Bending Arrangement

- Induction Hardened Rolls

- Separate Control Panel

- Drop end controlled from control panel in order to release easily bent metal sheet and lifted upper rolls

- Movement and parallelism adjustment of the rollers controlled from panel

- Reputed makes like – Rexroth, Yuken, Siemens, ABB etc.

Video Gallery

Image Gallery

Bending Hardox 400 2000 x 30 mm

"ABL" Plate Rolling Machine Working at a Shipyard