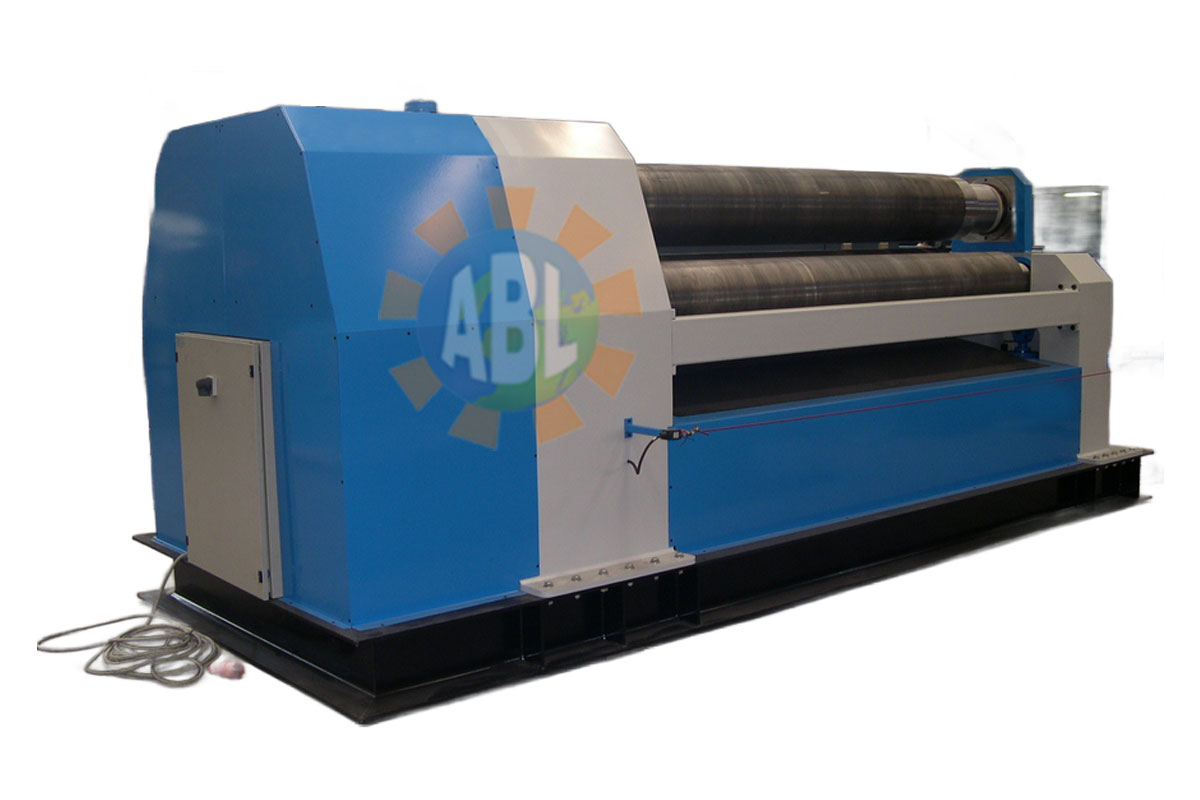

Hydraulic, Plate Rolling Machine (4 Roll Type)

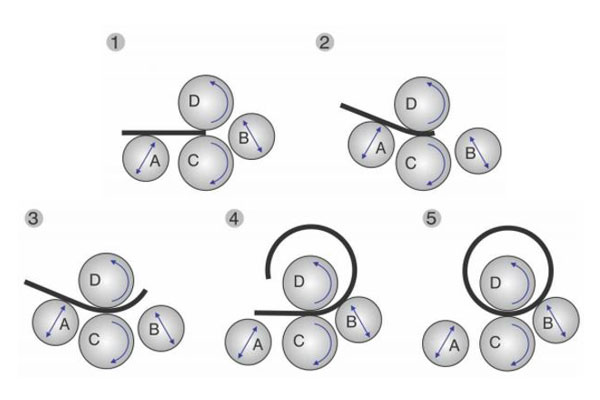

4 ROLL TYPE / DOUBLE PRE-PINCH TYPE / HYDRAULICALLY DRIVEN ROLLS

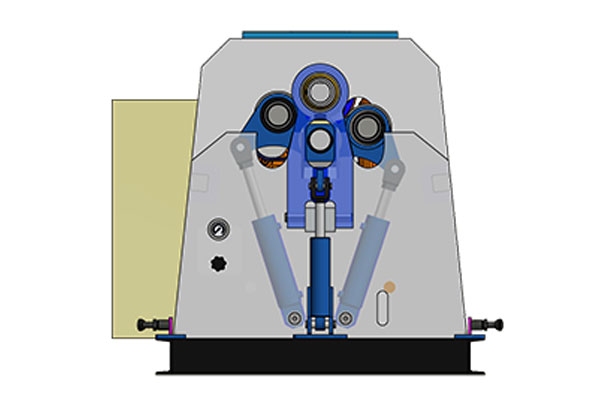

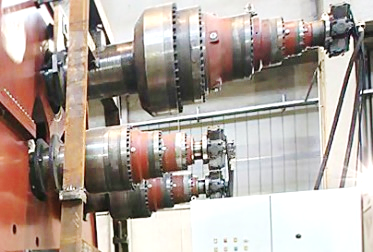

4 Rolls, Heavy Duty, Hydraulic Plate Rolling Machines produced by ABL have both the upper and the lower roll powered with hydraulic motor and planetary gear box. Rolls made of forged steel & all movements of rolls are hydraulic powered. The hydraulic motors of the two central rolls are coupled to their epicycloid gear boxes. The gear boxes are mounted directly on the rolls without secondary transmissions; this way there is no loss of power and no need of parts maintenance. Massive torsion bars grant the absolute parallelism. These torsion bars, together with all the hydraulic device, generate a system that gives absolute precision and versatility.

Planetary Gearboxes

Planetary drive eliminates complicated transmission systems which are not energy efficient. Delivers in excess of 98 % of all created energy to roll surface. Also eliminates the need for clutches and complicated synchronization devices

Planetary Guides

By using planetary guides, available on ABL Plate Rolls, we are able to keep approximately 50% more area of the plate under bend pressure during the rolling operation, thereby allowing our Plate Rolls to roll down to 1.1 the upper roll diameter. This allows the Rolls to have a 30% advantage on tight diameters.

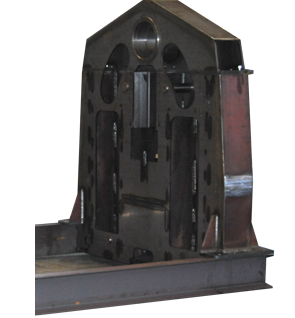

Body Structure

The strong structure is designed to fight the flexions due to the working effort, and it allows the top roll balancing, everything for the benefit of the final result accuracy. Also, the design is such that it requires minimum foundation work during installation at site.

Torsion Bar Parallelism

Unlike electronic systems or proportional value systems, which maintain a theoretical balance, ABL Plate Rollers maintains a mechanical finite parallelism through our exclusive torsion bar system which allows the machine to be adjusted to its full conical tilt and back to parallel in only seconds for the life of the machine.

Product Specifications

| Model | Working Length | Max. Thickness | Pre-Bending | Top Roller Ø | Bottom Roll Ø | Side Roll Ø | Motor Power | Length | Height | Width | Approx. Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| UOM | MM | MM | MM | MM | MM | MM | KW | MM | MM | MM | KGS. |

| 4RB 2004 | 2100 | 6 | 4 | 160 | 140 | 120 | 2.2 | 4140 | 1050 | 1150 | 2500 |

| 4RB 2006 | 2100 | 8 | 6 | 190 | 170 | 150 | 3.0 | 4140 | 1250 | 1380 | 3300 |

| 4RB 2008 | 2100 | 10 | 8 | 210 | 190 | 170 | 7.5 | 4140 | 1300 | 1400 | 4400 |

| 4RB 2010 | 2100 | 13 | 10 | 230 | 210 | 190 | 7.5 | 4140 | 1300 | 1400 | 4650 |

| 4RB 2013 | 2100 | 16 | 13 | 270 | 250 | 210 | 11 | 4522 | 1438 | 1520 | 6000 |

| 4RB 2016 | 2100 | 20 | 16 | 300 | 270 | 210 | 15 | 4532 | 1490 | 1730 | 7000 |

| 4RB 2020 | 2100 | 25 | 20 | 330 | 300 | 240 | 15 | 4585 | 1600 | 1850 | 9150 |

| 4RB 2025 | 2100 | 30 | 25 | 360 | 330 | 250 | 19 | 4600 | 2020 | 1920 | 10500 |

| 4RB 2030 | 2100 | 40 | 30 | 390 | 360 | 300 | 22 | 5050 | 2120 | 2200 | 18800 |

| 4RB 2035 | 2100 | 45 | 35 | 430 | 390 | 330 | 30 | 5300 | 2585 | 2300 | 24800 |

| 4RB 2040 | 2100 | 50 | 40 | 460 | 420 | 360 | 37 | 5480 | 2585 | 2300 | 28000 |

| 4RB 2050 | 2100 | 60 | 50 | 510 | 460 | 390 | 45 | 5680 | 2900 | 3000 | 35000 |

| 4RB 2060 | 2100 | 70 | 60 | 540 | 510 | 440 | 55 | 5700 | 2950 | 3000 | 40000 |

| 4RB 2504 | 2600 | 6 | 4 | 190 | 170 | 150 | 3.0 | 4545 | 1250 | 1380 | 3600 |

| 4RB 2506 | 2600 | 8 | 6 | 210 | 190 | 170 | 7.5 | 4650 | 1300 | 1380 | 4600 |

| 4RB 2508 | 2600 | 10 | 8 | 230 | 210 | 190 | 7.5 | 4650 | 1300 | 1380 | 5560 |

| 4RB 2510 | 2600 | 13 | 10 | 270 | 250 | 210 | 11 | 5050 | 1430 | 1520 | 7200 |

| 4RB 2513 | 2600 | 16 | 13 | 300 | 270 | 210 | 11 | 5050 | 1490 | 1730 | 8110 |

| 4RB 2516 | 2600 | 20 | 16 | 330 | 300 | 240 | 15 | 5050 | 1610 | 1840 | 10800 |

| 4RB 2520 | 2600 | 25 | 20 | 360 | 330 | 250 | 18.5 | 5050 | 1680 | 1900 | 11800 |

| 4RB 2525 | 2600 | 30 | 25 | 390 | 360 | 300 | 22 | 5250 | 1990 | 2100 | 15800 |

| 4RB 2530 | 2600 | 40 | 30 | 430 | 390 | 330 | 30 | 5550 | 2180 | 2200 | 22300 |

| 4RB 2535 | 2600 | 45 | 35 | 460 | 420 | 360 | 30 | 5800 | 2585 | 2300 | 28500 |

| 4RB 2540 | 2600 | 50 | 40 | 510 | 460 | 390 | 45 | 5800 | 2585 | 2300 | 31000 |

| 4RB 2550 | 2600 | 60 | 50 | 540 | 510 | 440 | 55 | 6100 | 2950 | 3000 | 42000 |

| 4RB 3004 | 3100 | 6 | 4 | 210 | 190 | 170 | 7.5 | 5142 | 1300 | 1390 | 4800 |

| 4RB 3006 | 3100 | 8 | 6 | 230 | 210 | 190 | 7.5 | 5142 | 1300 | 1390 | 6000 |

| 4RB 3008 | 3100 | 10 | 8 | 270 | 250 | 210 | 11 | 5522 | 1450 | 1520 | 7800 |

| 4RB 3010 | 3100 | 13 | 10 | 300 | 270 | 210 | 11 | 5532 | 1490 | 1730 | 8800 |

| 4RB 3013 | 3100 | 16 | 13 | 330 | 300 | 240 | 11 | 5532 | 1610 | 1840 | 11000 |

| 4RB 3016 | 3100 | 20 | 16 | 360 | 330 | 250 | 15 | 5585 | 1680 | 1900 | 13000 |

| 4RB 3020 | 3100 | 25 | 20 | 390 | 360 | 300 | 18.5 | 5590 | 1980 | 2100 | 17500 |

| 4RB 3028 | 3100 | 33 | 28 | 430 | 390 | 330 | 22 | 5740 | 2180 | 2200 | 22500 |

| 4RB 3030A | 3100 | 35 | 30 | 440 | 410 | 340 | 22 | 6060 | 2585 | 2200 | 23000 |

| 4RB 3030B | 3100 | 40 | 32 | 460 | 420 | 360 | 30 | 6060 | 2585 | 2300 | 30000 |

| 4RB 3035A | 3100 | 45 | 35 | 480 | 440 | 380 | 30 | 6270 | 2585 | 2300 | 31500 |

| 4RB 3035B | 3100 | 45 | 35 | 510 | 460 | 390 | 45 | 6270 | 2925 | 2300 | 33500 |

| RB 3040 | 3100 | 50 | 40 | 540 | 500 | 440 | 55 | 6680 | 3000 | 3000 | 42000 |

| 4RB 3050 | 3100 | 60 | 50 | 560 | 520 | 450 | 60 | 7000 | 3100 | 3100 | 45000 |

| 4RB 3060 | 3100 | 70 | 60 | 580 | 540 | 480 | 65 | 7100 | 3200 | 3200 | 47000 |

| 4RB 3070 | 3100 | 85 | 70 | 600 | 560 | 500 | 70 | 7250 | 3240 | 3250 | 51500 |

| 4RB 3080 | 3100 | 95 | 80 | 610 | 570 | 500 | 75 | 7250 | 3240 | 3300 | 53000 |

| 4RB 3090 | 3100 | 105 | 90 | 630 | 600 | 520 | 80 | 7400 | 3300 | 3400 | 56500 |

| 4RB 30100 | 3100 | 120 | 100 | 650 | 620 | 540 | 90 | 7800 | 3300 | 3450 | 60000 |

| 4RB 30120 | 3100 | 140 | 120 | 700 | 680 | 580 | 100 | 8000 | 3300 | 3500 | 68000 |

| 4RB 4004 | 4100 | 6 | 4 | 270 | 250 | 210 | 7.5 | 6520 | 1438 | 1520 | 8900 |

| 4RB 4006 | 4100 | 8 | 6 | 300 | 270 | 210 | 7.5 | 6530 | 1490 | 1730 | 9950 |

| 4RB 4008 | 4100 | 10 | 8 | 330 | 300 | 240 | 7.5 | 6585 | 1600 | 1840 | 15100 |

| 4RB 4010 | 4100 | 13 | 10 | 360 | 330 | 250 | 11 | 6545 | 1680 | 1900 | 16000 |

| 4RB 4013 | 4100 | 16 | 13 | 390 | 360 | 300 | 15 | 7240 | 1990 | 2100 | 20800 |

| 4RB 4016 | 4100 | 20 | 16 | 430 | 390 | 330 | 18.5 | 7060 | 2180 | 2200 | 26000 |

| 4RB 4020 | 4100 | 25 | 20 | 460 | 420 | 360 | 22 | 7480 | 2585 | 2300 | 36000 |

| 4RB 4025 | 4100 | 30 | 25 | 510 | 460 | 390 | 30 | 7500 | 2750 | 2500 | 38000 |

| 4RB 4028 | 4100 | 35 | 28 | 540 | 510 | 440 | 37 | 7700 | 2825 | 3000 | 55000 |

Note: Data Based Upon steel 240 N/mm2 yield point * For cone bending, all bending values must be reduced 50%

* All specifications are subject to change without notice.

Standard Accessories

- Overload protection

- Hydraulic top and side rolls

- Digital readout for top and side rolls

- Hydraulic closure for easy removal of bent parts

- Welded & Heavy Steel Frame

- Induction hardened rolls made of SAE 1050 (CK 45) steel

- Conical bending device

- Automatic lubrication

- Electronic/mechanical balancing device

- 2 bending speeds. Operation Manual

Optional Accessories

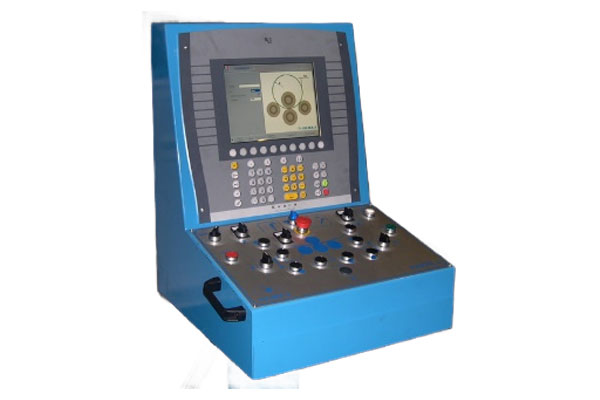

- NC or CNC control system for bend automation

- Central overhead JIB Crane Support

- Lateral Supports

- Conveyorized Material Feeding

- Continuous Bending Speed

- Heat Exchanger for Hydraulic Oil

- Hydraulic work piece ejector

- Ground and polished rolls

- Small top roller for minimum bending radii

Video Gallery

Image Gallery