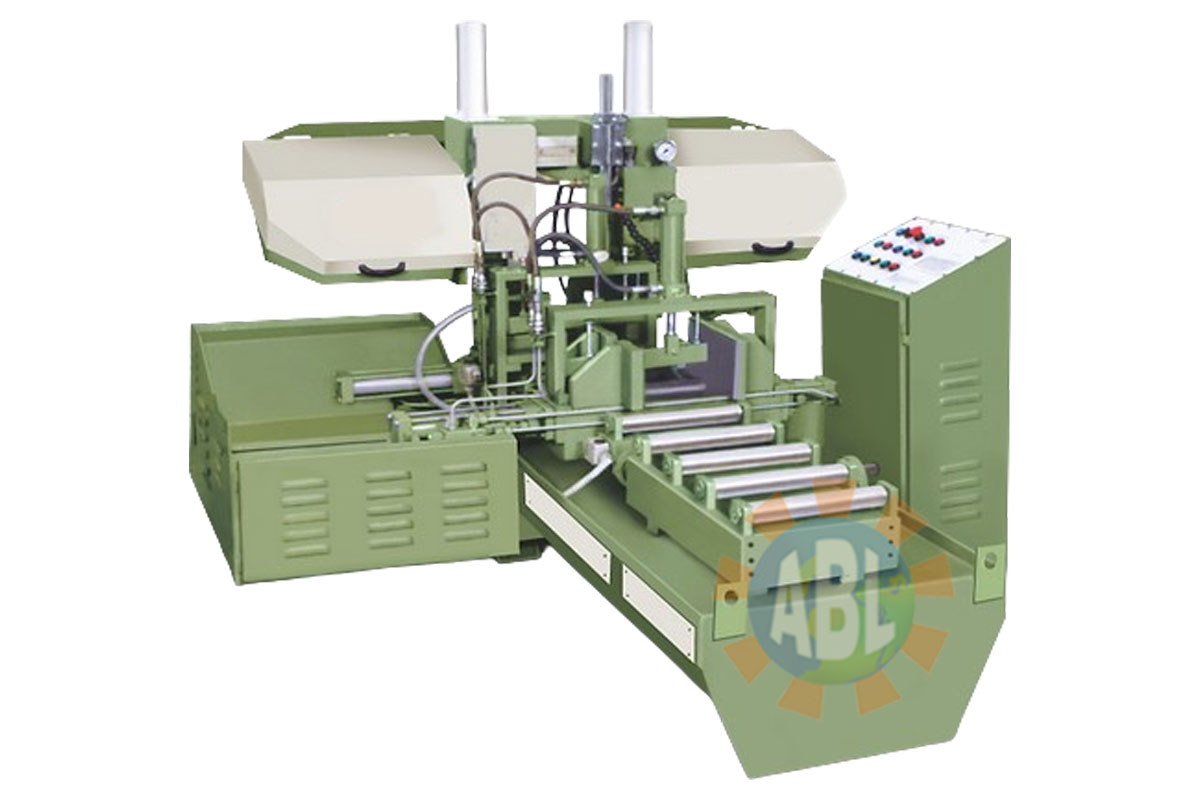

Fully-Automatic, Bandsaw Machine

HYDRAULIC/ DOUBLE COLUMN TYPE / HEAVY OPERATIONS

Fully-Automatic, Double Column Type, Hydraulic, Metal Cutting Bandsaw Machine with Automatic Feeding System to reduce man-power & expedite the production. This machine is most suitable & preferred for mass & heavy production areas.

Product Specifications

| Model [FA Series] | ABL-240 DCA | ABL-300 DCA | ABL-420 DCA |

|---|---|---|---|

| ROUND CUTTING CAPACITY | 240 | 310 | 420 |

| SQ. CUTTING CAPACITY | 240 x 240 | 310 x 310 | 420 x 420 |

| BUNDLE CUTTING CAPACITY | 210 X 150 | 300 X 150 | 410 X 150 |

| BLADE DIMENSION | 3760x27x0.9 | 4100x34x1.1 | 5450x41x1.3 |

| JOB STROKE | 350 | 350 | 350 |

| BLADE LINEAR SPEED | 20/30/40/50/75 | ||

| SAW DRIVE MOTOR (HP) | 2 & 1 | 3 & 1 | 5 & 2 |

| COOLANT PUMP | 0.16 | 0.16 | 0.16 |

| WIRE BRUSH MOTOR (HP) | 0.25 | 0.25 | 0.25 |

| HYD. TANK CAP. (LTR) | 80 | 80 | 80 |

| COOLANT CAPACITY (LTR) | 80 | 80 | 80 |

| MACHINE DIM. (L x W x H) | 2 x 1 x 1.3 | 2.3 x 1 x 1.3 | 2.5 x 1 x 1.7 |

| APPROX. WEIGHT (KG) | 2050 | 2400 | 2750 |

Note: HIGHER SIZES & MORE DETAILS, AVAILABLE ON REQUEST.

Standard Features

- V-belt & Step Pulley

- One piece of Bi-metal Blade with each machine

- Power driven wire brush for continue cleaning bi-metal blade

- Shuttle type automatic feeding material system

- Automatic working height control device & fast approach

- Hydraulic vice clamping / declaiming device

- Hydraulic blade tension and blade breakage detector device

- PLC base control system

Optional Accessories

- Automatic chip conveyor system

- Infinitely variables speed control by A.C. frequency drive

- Hydraulic bundle cutting attachment

- Job roller stand (1 meter long)

- Chip removing wire brush

- Bi-metal blade

- Centralized lubrication system

Salient Features

- Saw head unit supported by two rigid hard-chrome plated & ground vertical columns

- The quick approach arm eliminates the need for the operator to manually adjust the blade height

- Saw head up & down motion is controlled by hydraulic cylinder

- The guide ensures accurate cutting & long blade life

- Jaw Clamping is controlled by hydraulic cylinder & valves. The jaws of the front & rear vices are in one straight line and perpendicular to the blade

- Split Front Vice design permits the work piece to be automatically indexed

- Shuttle type automatic feeding material system is done by indexing

- A nesting fixture set consists of hydraulically operated vertical clamps which are mounted on the rear and front vices

- This makes it possible to cut multiple pieces at a time

- The power-driven brush keeps the blade teeth free from chips for smoother cutting & increase the performance and life of the blade

Video Gallery

Image Gallery