Hydraulic, Iron Worker

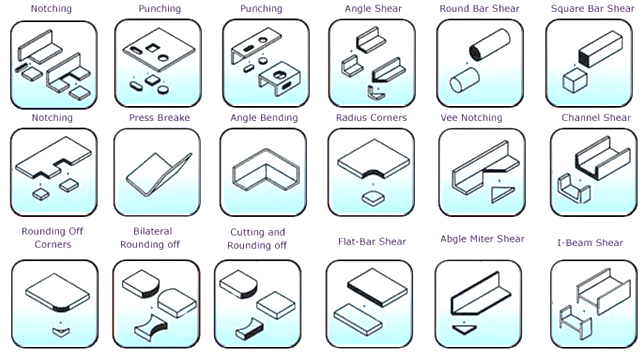

5 IN 1 /FLAT SHEARING/PUNCHING/ANGLE & CHANNEL CUTTING/ NOTCHING

Hydraulic, Iron Worker “HAWK” series are well-engineered ironworkers built for high power, quality, and reliability. These ironworkers are 5 in 1 multipurpose machine & most suited in fabrication shops for various section cutting purposes.

Applications

5 in 1 Hydraulic Iron Worker Machines are generally used in Fabrication Shops. It’s a multi-purpose machine capable for Punching, Angle Cutting, C-Channel Cutting, I-Beam Cutting, Roand/Sq. Bar Cutting, Flat Plate Shearing.

Product Specifications

| DESCRIPTION | HAWK-55 | HAWK-65 | HAWK-85 | HAWK-110 | HAWK-135 | HAWK-165 | HAWK-220 |

|---|---|---|---|---|---|---|---|

| PUNCHING | |||||||

| Punching Pressure (Tons) | 55 | 65 | 85 | 110 | 135 | 165 | 220 |

| Punch Capacity (Dia. x Thk) | 22 x 16 45 x 8 | 22 x 20 50 x 9 | 26 x 22 50 x 12 | 30 x 25 50 x 15 | 33 x 28 50 x 18 | 36 x 32 50 x 23 | 40 x 38 50 x 30 |

| Through Depth (2 Options) | 275 / – | 310 / 510 | 310 / 510 | 310 / 510 | – / 570 | – / 570 | – / 570 |

| Max. Stroke Length | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Cycle / Min (20 mm Stroke) | 25 / 32 | 20 | 20 | 20 | 20 | 25 | 25 |

| Working Height up to Die | 910 | 910 | 950 | 950 | 1020 | 1050 | 1050 |

| FLAT SHEARING | |||||||

| Flat Bar Shearing (W x Thk) | 300 x 12 240 x 16 | 350 x 15 240 x 20 | 460 x 15 300 x 20 | 610×16 400×20 | 610×18 400×25 | 760 x 20 400 x 30 | 700 x 25 425 x 30 |

| Blade Length | 310 | 360 | 465 | 620 | 620 | 770 | 720 |

| Angle Flange Trim | 65 | 75 | 100 | 100 | 100 | 120 | 120 |

| Working Height | 820 | 920 | 920 | 950 | 950 | 950 | 950 |

| ANGLE SHEARING | |||||||

| 90⁰ Shearing | 100 x 100 x 10 | 130 x 130 x 13 | 152 x 152 x 13 | 152 x 152 x 15 | 152 x 152 x 18 | 200 x 200 x 20 | 200 x 200 x 20 |

| 45⁰ Shearing | 50 x 50 x 6 | 65 x 65 x 8 | 80 x 80 x 10 | 80 x 80 x10 | 80 x 80 x 10 | 80 x 80 x 10 | 100 x 100 x 10 |

| Working Height | 1080 | 1150 | 1150 | 1150 | 1160 | 1160 | 1160 |

| BAR SHEARING | |||||||

| Round Bar Shear | 32 | 40 | 50 | 50 | 50 | 60 | 70 |

| Square Bar Shear | 32 x 32 | 38 x 38 | 50 x 50 | 50 x 50 | 50 x 50 | 60 x 60 | 60 x 60 |

| Channel Shear * | 125 | 152 | 180 | 180 | 200 | 250 | 300 |

| I-Beam Shear * | 125 | 152 | 180 | 180 | 180 | 200 | 300 |

| Working Height | 1150 | 1300 | 1300 | 1315 | 1315 | 1375 | 1375 |

| NOTCHING | |||||||

| Rectangular (W x D x T*) | 50.8 x 90 x 6 | 50.8 x 90 x 9 | 50.8 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 13 | 63.5 x 90 x 16 | 63.5 x 90 x 18 |

| Vee-Notcher (Side x Side x T) | 80 x 50 x 6 | 90 x 90 x 8 | 90 x 90 x 10 | 105 x 105 x 12 | 105 x 105 x 13 | 105 x 105 x 16 | 105 x 105 x 16 |

| Large V-Notcher (S x S x T*) | / | 145 x 145 x 8 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 13 | 145 x 145 x 13 | 145 x 145 x 15 |

| Working Height | 850 | 850 | 860 | 860 | 860 | 920 | 920 |

| SPECIAL TOOLINGS | |||||||

| Single Vee- Press Brake (W x T) | 250 x 10 | 250 x 15 | 250 x 15 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi Vee-Press Brake (W x T) | 400 x 5 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 6 | 700 x 6 |

| Angle Bending | 76 x 8 | 102 x 6 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 |

| Pipe Notching (Dia.) | 114 | 114 | 114 | 114 | 114 | 114 | 1114 |

| OTHERS | |||||||

| Electric Motor (HP) | 7.5 | 7.5 | 10 | 10 | 15 | 20 | 25 |

| Approx. Net Weight (Kgs.) | 2300 | 2800 | 3100 | 3750 | 5000 | 6300 | 8000 |

| Approx. Machine Dim. (in Mtr.) | 1.8 x 0.8 x 1.8 | 2.0 x 0.8 x 2.0 | 2.1 x 0.8 x 2.0 | 2.4 x 1.05 x 2.1 | 2.5 x 1.1 x 2.2 | 2.6 x 1.1 x 2.2 | 2.7 x 1.2 x 2.3 |

Note: * Above configurations based on Material Strength of 450 N/MM2

* Optional @ Extra Cost

Standard Accessories

- Electrical Motor

- Elec. Control Pendent

- Machine Light

- 1 Set of Die

- Manual Job Clamping Device

- Instruction & Maintenance Manual

Optional Accessories

- Additional Set of Dies

- 2 Years Normal Maintenance Spares

- Any extra tooling

- Blade Sets

Video Gallery

Image Gallery