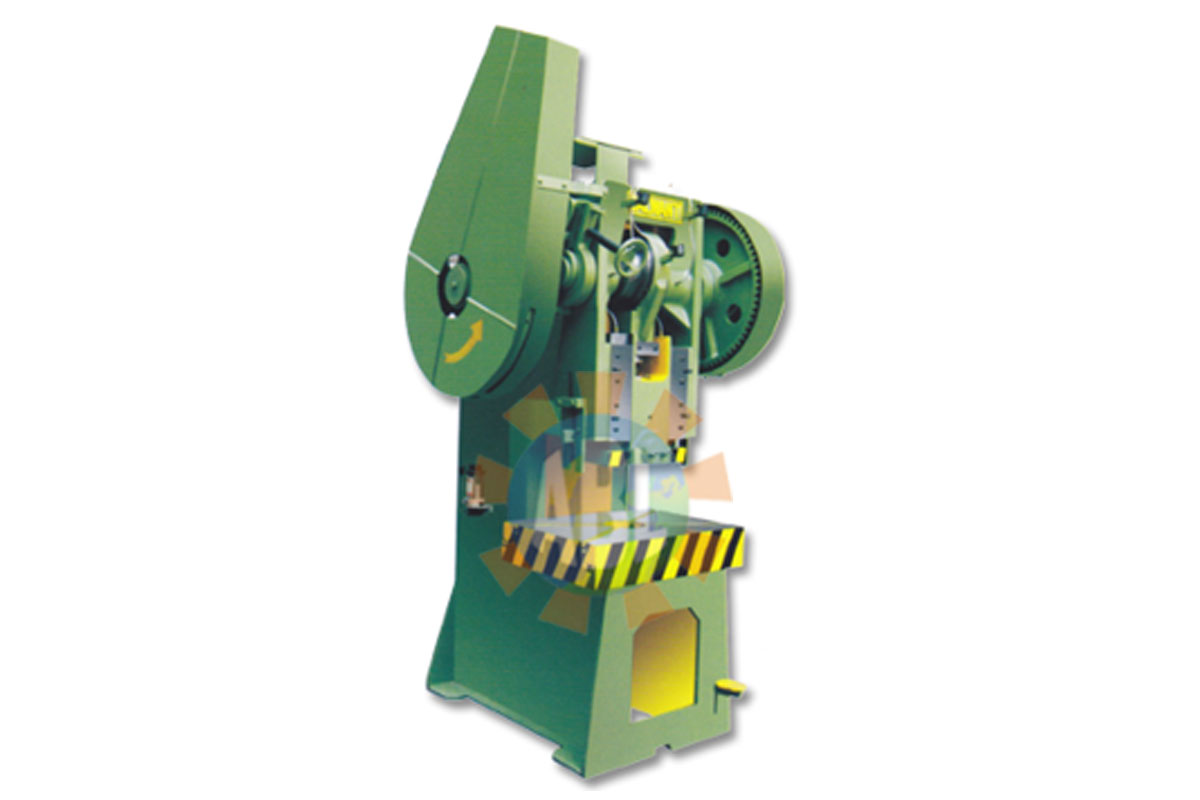

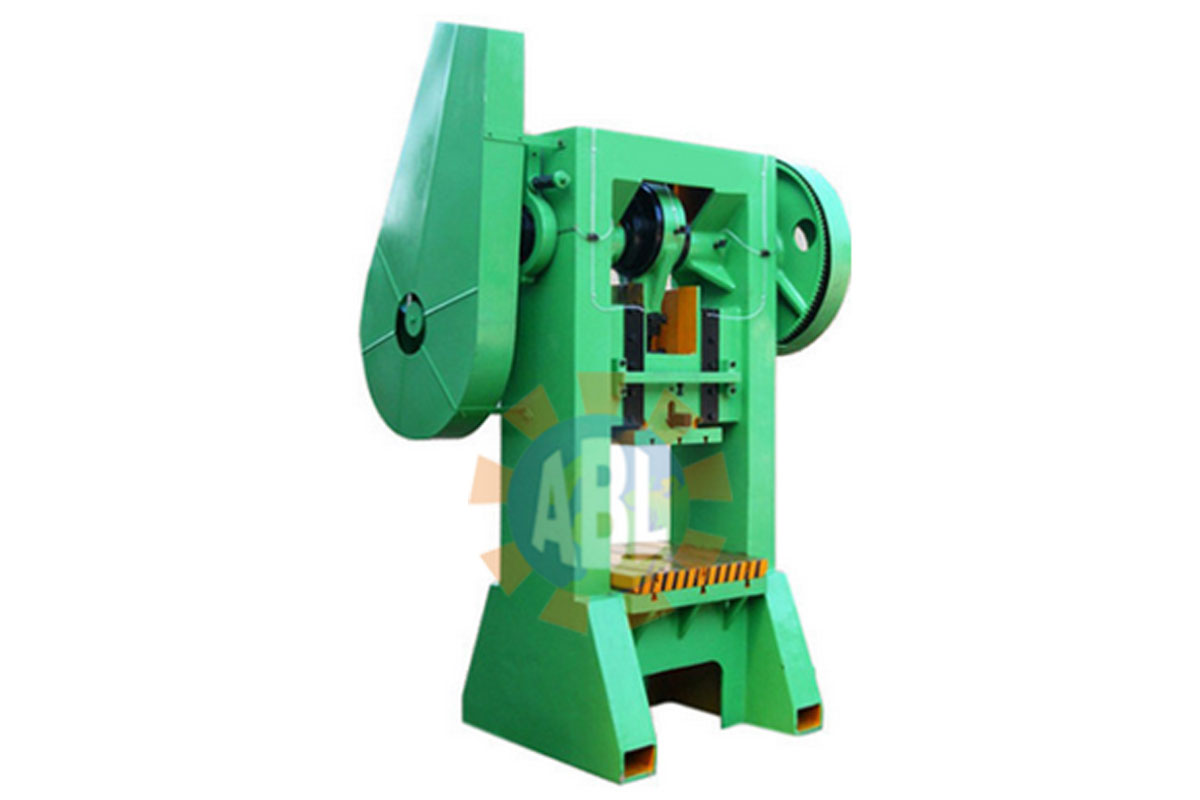

Power Presses

Power Press Machines Manufacturers in India

In the field of metal forming and fabrication, power press machines are essential for achieving precision, efficiency, and productivity. As a leading power press machine manufacturer in India, ABL Machine Tools provides high-quality machines designed to meet the diverse needs of modern industries. With a strong presence in India, Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, ABL Machine Tools has become a trusted name for reliable, durable, and efficient sheet metal machinery.

Wide Range of Power Press Machines

ABL Machine Tools offers a comprehensive range of power press machines, including mechanical, hydraulic, and pneumatic variants. These machines are designed to perform operations such as punching, bending, shearing, forming, and stamping with high accuracy and repeatability. Industries such as automotive, aerospace, construction, appliance manufacturing, and heavy engineering rely on ABL’s power press machines for precision and consistent output.

Customized Solutions for Every Manufacturing Requirement

Every industry has unique production challenges, and ABL Machine Tools specializes in providing custom-made power press machines to suit specific requirements. Machines can be tailored based on tonnage capacity, stroke length, bed size, automation level, and safety features. This customization ensures optimal performance, reduces downtime, and enhances productivity for clients across various sectors.

Global Reach and Quality Commitment

ABL Machine Tools has earned recognition not only in India but also in international markets. Its power press machines are exported to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, where they are trusted for their precision, durability, and long-term performance. Each machine undergoes stringent quality checks and is built using premium-grade materials to ensure reliability in demanding industrial environments.

Why Choose ABL Machine Tools?

- Extensive range of mechanical, hydraulic, and pneumatic power presses.

- Custom-built machines designed to match specific production goals.

- Global presence with satisfied clients in India and the Middle East.

- Focus on precision, durability, and operational efficiency.

- Reliable after-sales support including spare parts and technical assistance.

FAQ – Power Press Machines

What is a power press machine?

A power press machine is an industrial tool used for metal forming operations such as punching, bending, shearing, stamping, and forming. It uses mechanical, hydraulic, or pneumatic force to shape or cut metal with high precision.

What types of power press machines are available?

The main types include:

- Mechanical Power Presses – Operate using mechanical cams for high-speed operations.

- Hydraulic Power Presses – Provide precise control and high tonnage capacity.

- Pneumatic Power Presses – Use compressed air for lighter-duty operations and faster cycles.

What industries use power press machines?

Power press machines are widely used in automotive, aerospace, appliance manufacturing, construction, shipbuilding, and heavy engineering industries for shaping and forming sheet metal and components.

How do I choose the right power press machine?

Key factors to consider include tonnage capacity, stroke length, bed size, production volume, type of operation, and level of automation. ABL Machine Tools also provides customized power press machines tailored to specific production needs.

Can power press machines be customized?

Yes. ABL Machine Tools offers custom-built power press machines with options for tonnage, automation, safety features, stroke length, and bed size to meet unique industrial requirements.

Why are Indian power press manufacturers trusted globally?

Manufacturers like ABL Machine Tools are known for durable, reliable, and cost-effective machines. Their exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt highlight international trust in their engineering quality.

What are the advantages of using a power press machine?

- High precision and repeatability

- Faster production cycles

- Ability to perform multiple metal forming operations

- Durable construction and long service life

- Reduced labor and operational costs

What maintenance is required for power press machines?

Routine maintenance includes lubrication of moving parts, inspection of mechanical or hydraulic components, checking alignment, ensuring safety systems are functional, and following the manufacturer’s maintenance guidelines for optimal performance.