Grinding Machines

Grinding Machines Manufacturers in India

In precision engineering and industrial manufacturing, grinding machines manufacturers in India play a pivotal role in delivering equipment that ensures accuracy, smooth finishes, and high productivity. Among the leading names in this domain, ABL Machine Tools stands out as a trusted manufacturer of a wide range of machine tools. With a strong presence across India, Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, ABL Machine Tools is recognized globally for its high-quality grinding machines and customized solutions.

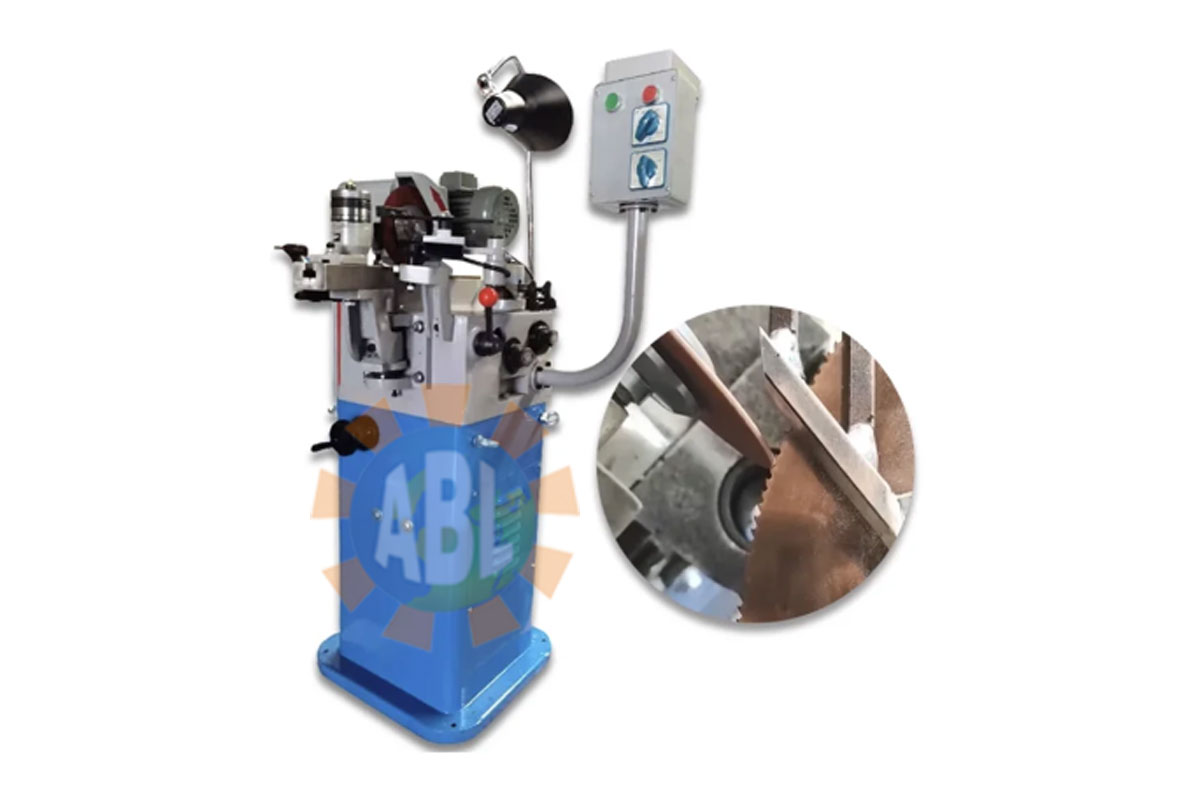

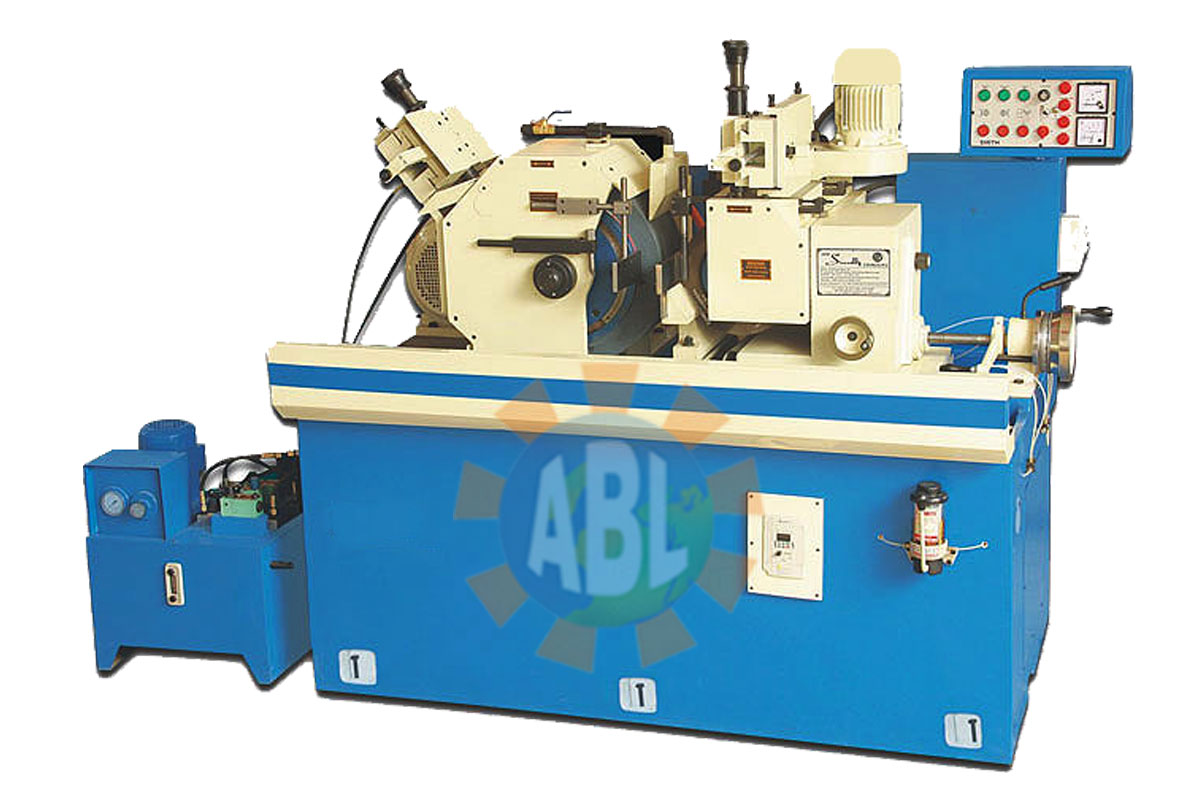

Wide Range of Grinding Machines

ABL Machine Tools offers an extensive portfolio of grinding machines designed to meet diverse industrial needs. The range includes surface grinders, cylindrical grinders, centerless grinders, and CNC grinding machines. These machines are engineered for precision operations such as finishing, sharpening, and shaping metal and non-metal components. Industries such as automotive, aerospace, heavy engineering, tool manufacturing, and metal fabrication rely on these machines for consistent accuracy and long-term durability.

Customized Solutions for Manufacturing Needs

Every manufacturing unit has unique production requirements, and ABL Machine Tools excels in providing custom-made grinding machines. The machines can be tailored according to spindle speed, table size, grinding wheel specifications, and automation features to optimize productivity and reduce operational downtime. This customization ensures that clients achieve precise machining outcomes aligned with their specific production goals.

Global Presence and Trusted Quality

ABL Machine Tools has earned a strong reputation not only in India but also in international markets. Its machines are exported to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, reflecting global trust in the brand. Each grinding machine is manufactured with premium-grade materials and undergoes rigorous quality testing to ensure durability, precision, and reliable performance in demanding industrial conditions.

Why Choose ABL Machine Tools?

- Comprehensive range of grinding machines for various applications.

- Tailor-made solutions to meet unique client requirements.

- International presence across India and Middle Eastern markets.

- Focus on precision, durability, and innovation.

- Long-term support and after-sales service for optimal machine performance.

Grinding Machines Manufacturers in Saudi Arabia, Grinding Machines Manufacturers in UAE, Grinding Machines Manufacturers in Qatar, Grinding Machines Manufacturers in Kuwait, Grinding Machines Manufacturers in Bahrain, Grinding Machines Manufacturers in Oman, Grinding Machines Manufacturers in Egypt

Frequently Asked Questions (FAQ) on Grinding Machines

What is a grinding machine?

A grinding machine is a precision tool used to finish surfaces, sharpen tools, and shape materials by removing small amounts of material through abrasive action. It ensures high accuracy and smooth finishes in metal and non-metal components.

What are the types of grinding machines?

Common types include:

- Surface Grinding Machine

- Cylindrical Grinding Machine

- Centerless Grinding Machine

- CNC Grinding Machine

- Internal Grinding Machine

What industries use grinding machines?

Grinding machines are widely used in automotive, aerospace, heavy engineering, metal fabrication, tool manufacturing, and general industrial workshops where precision and smooth finishes are critical.

What operations can be performed on a grinding machine?

Typical operations include finishing flat or curved surfaces, sharpening cutting tools, cylindrical grinding, internal and external surface grinding, and achieving high-precision dimensional tolerances.

How do I choose the right grinding machine?

The choice depends on factors like the type of material, size of the workpiece, required surface finish, production volume, and whether manual or automated operation is needed. ABL Machine Tools also offers custom-made grinding machines tailored to production goals.

Why are Indian grinding machine manufacturers trusted globally?

Indian manufacturers, including ABL Machine Tools, are recognized for producing durable, high-precision, and cost-effective machines. Their exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt demonstrate global reliability and trust.

Can grinding machines be customized?

Yes. ABL Machine Tools provides customized grinding machines with variations in grinding wheel size, spindle speed, table capacity, and automation features to meet unique industrial requirements.

How should grinding machines be maintained?

Regular maintenance includes proper lubrication, cleaning abrasive residues, checking alignment and wheel balance, replacing worn-out components, and following the manufacturer’s service guidelines to ensure long machine life and consistent performance.