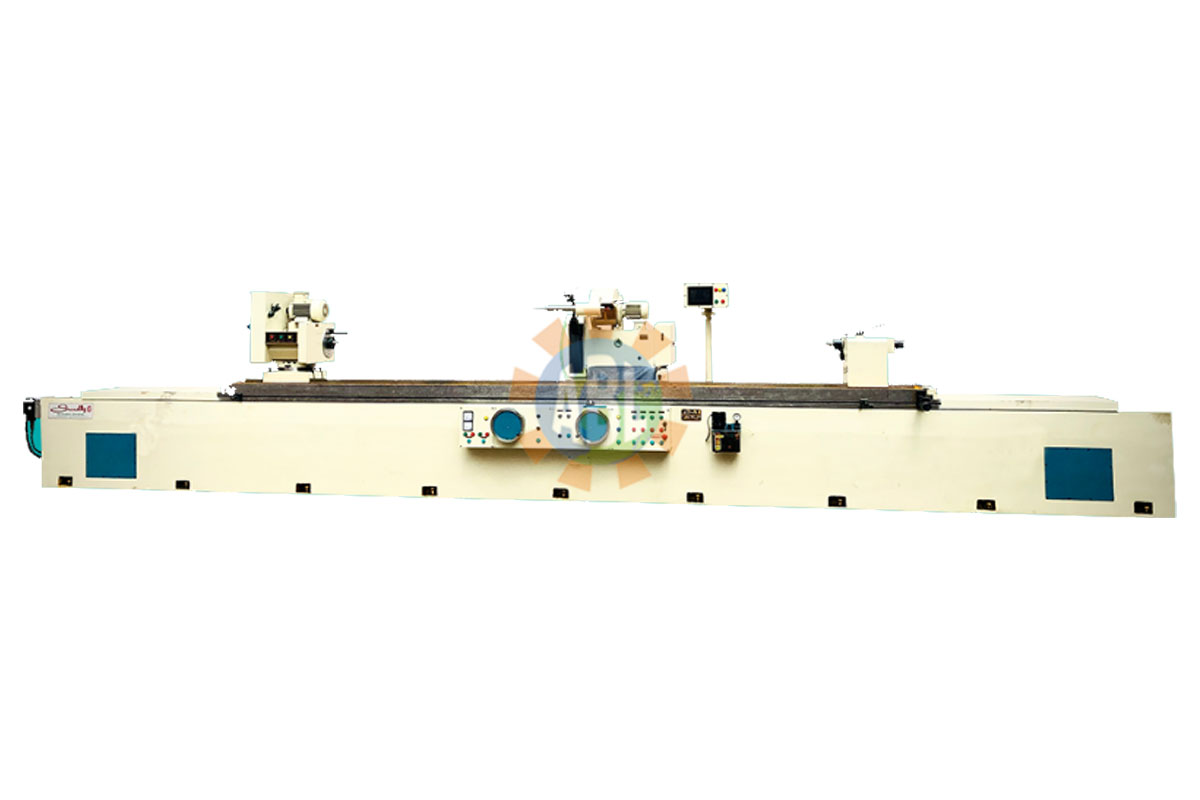

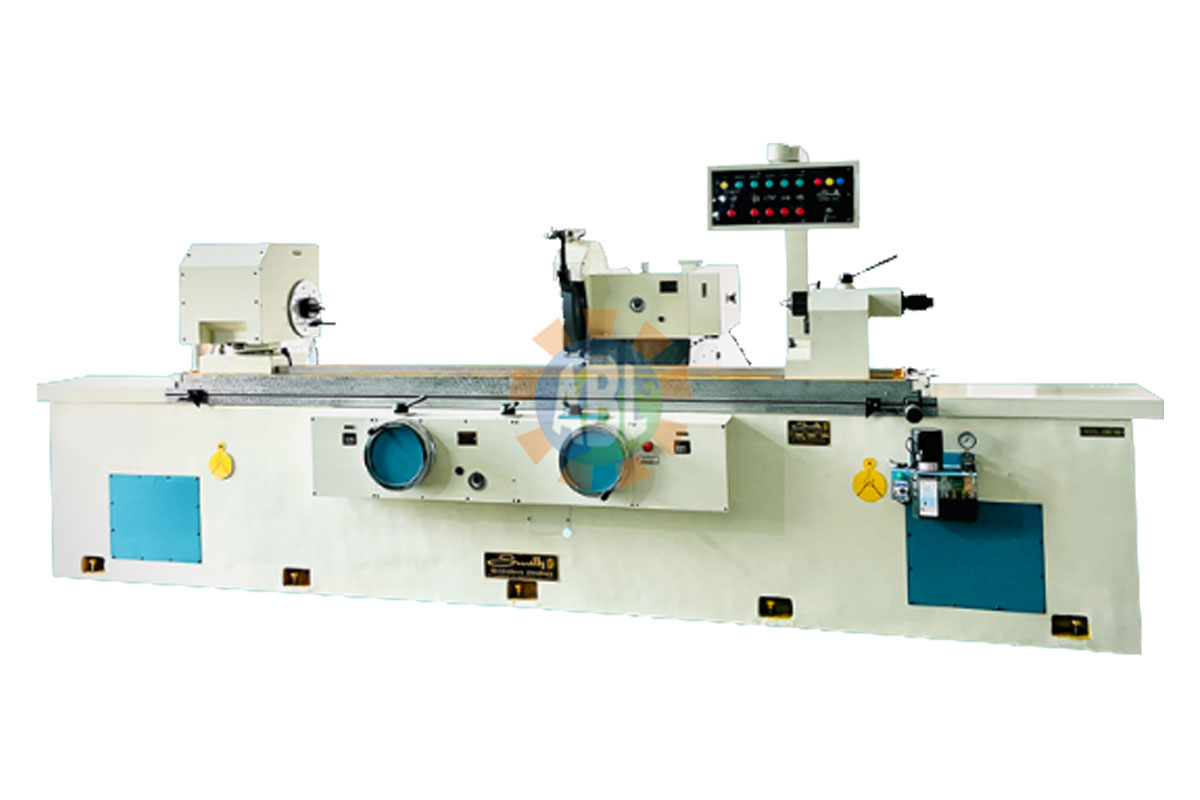

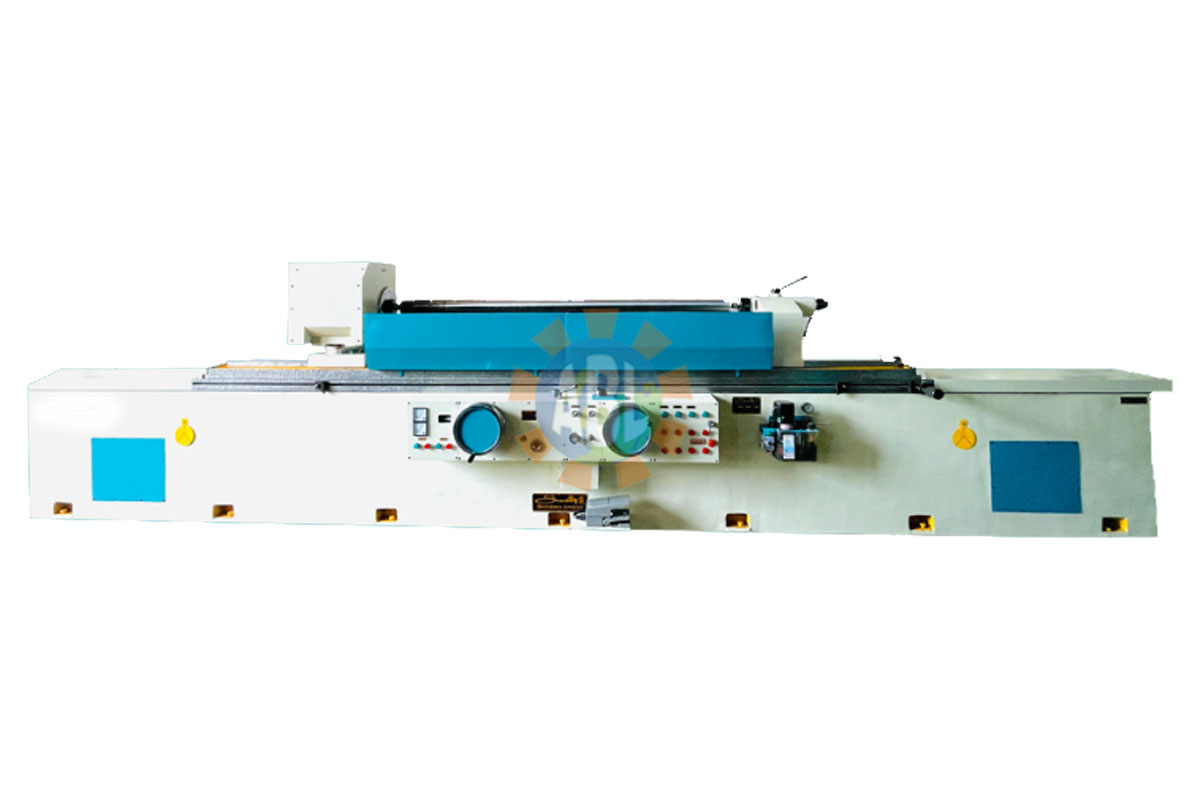

Universal Cylindrical Grinder

MECHANICAL-HYDRAULIC-PLC MODE OPTIONS / PRECISION GRINDING APPLICATIONS

Universal Cylindrical Grinding Machines are useful for material removal with geometrically non-defined, bonded cutting edges, where the relative movement between tool & workpiece is rotational & linear. The machine is used for precision tool room & production application for components. The Internal Grinding Head with the machine makes it an ideal choice for diverse applications at various industries.

Product Specifications

| MODELS | CG-450 | CG-600 | CG-800 | CG-1000 | CG-1250 | CG-1500 | CG-2000 | CG-2500 | CG-3000 | CG-4000 | CG-5000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| GENERAL CAPACITY | |||||||||||

| Distance Between Centers | 450 MM | 600 MM | 800 MM | 1000 MM | 1250 MM | 1500 MM | 2000 MM | 2500 MM | 3000 MM | 4000 MM | 5000 MM |

| Table Swivel | 9+3 | 9+3 | 6+3 | 6+3 | 6+3 | 6+3 | 6+3 | 6+3 | 6+3 | 6+3 | 6+3 |

| Center Height | 140 MM | 140 MM | 140 MM | 155 MM | 155 MM | 250 MM | 250 MM | 250 MM | 250 MM | 300 MM | 300 MM |

| Swing Over Table | 270 MM | 270 MM | 270 MM | 300 MM | 300 MM | 490 MM | 490 MM | 490 MM | 490 MM | 590 MM | 590 MM |

| WORK HEAD | |||||||||||

| Work Head Speeds | Variable – AC Drive | ||||||||||

| Morse Taper Center | MT 3 | MT 3 | MT 3 | MT 4 | MT 4 | MT 5 | MT 5 | MT 5 | MT 5 | MT 5 | MT 5 |

| Work Head Swivel (Deg.) | 45 + 45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 |

| Spindle Bore | 18 MM | 18 MM | 18 MM | 18 MM | 18 MM | 18 MM | 18 MM | 18 MM | 18 MM | 18 MM | 18 MM |

| TABLE | |||||||||||

| Table Movement (Stepless) | MECHANICAL/HYDRAULIC/SERVO | HYDRAULIC/SERVO | |||||||||

| WHEEL HEAD | |||||||||||

| Rapid Approach | 50 MM | 50 MM | 50 MM | 50 MM | 50 MM | 50 MM | 50 MM | 50 MM | 50 MM | 50 MM | 50 MM |

| Wheel Head with Hand Wheel | 175 MM | 175 MM | 175 MM | 175 MM | 175 MM | 250 MM | 250 MM | 250 MM | 250 MM | 300 MM | 300 MM |

| Increment with Hand Wheel | 0.005 MM | 0.005 MM | 0.005 MM | 0.001,0.01,0.1 | |||||||

| Swivel of Wheel Head (Deg.) | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 | 45+45 |

| Wheel Size (OD x ID x Width) | 350x127x38 MM | 400x127x38 MM | 500x254x50 MM | 600×304.8×60 MM | |||||||

| POWER | |||||||||||

| Wheel Head Motor | 3 HP | 3 HP | 3 HP | 3 HP | 3 HP | 5 HP | 5 HP | 5 HP | 5 HP | 10 HP | 10 HP |

| Work Head (Geared Motor) | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 1.5 HP | 1.5 HP | 1.5 HP | 1.5 HP | 3 HP | 3 HP |

| Table Feed (Induction or Servo) | 1 HP/1.5 KW | 2 HP/1.5 KW | 3 HP/3 KW | ||||||||

| Cross Feed | 1.5 KW | 1.5 KW | 1.5 KW | 1.5 KW | 1.5 KW | 1.5 KW | 1.5 KW | 1.5 KW | 1.5 KW | 1.5 KW | 1.5 KW |

| Internal Grinding Attachment | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1.5 HP | 1.5 HP | 1.5 HP | 1.5 HP | 1.5 HP | 1.5 HP |

| Coolant Pump | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP | 0.5 HP |

| Lubrication Pump | 90 W | 90 W | 90 W | 90 W | 90 W | 90 W | 90 W | 90 W | 90 W | 90W (2) | 90W (2) |

Standard Accessories

- Operator’s Control Pendent

- Electrical Panel & Acc.

- Machine Lamp

- Diamond Dresser

- Dead Centers

- Operational Tool Kit

- Foundation Bolt Kit

- Inst. & Maint. Manual

Optional Accessories

- PLC/ CNC Controllers

- Internal Grinding Attachment

- Balancing Stand

- Balancing Mandrel

- 3 Points Steady Rest

- Two points Steady Rest

- Radius Truing Device

- Spare wheel Flange

- Independent Four Jaws Chuck

- Magnetic Coolant Pump

- Grinding Gauge

- 2 Years Normal Spare Set

Salient Features

- Rigidly Constructed Graded Grey Casting with Extra Heavy Ribs

- Tool Room and Mass Production

- Rapid approach Z and X Axis

- Variable Speeds of Work Head

- Antifriction Self Lubrication Turcite Coating on Bed Ways

- Tapered Angle Table for Best Gripping Head Stock and Tail Stock

- All Spindles and Shafts made of Nickel Alloy Steel hardened and precisely ground.

- High precision Class Bearings, Bushes and Spindle Cartridges are available as per Customer’s requirements

- Power Operated Tail Stock for Hydraulic Machines.

- Hydraulic Power packs Yuken/ Rexroth

- Energy Efficient Motors and Electrical Switch Gears of World Standards.

- Centralized automatic Lubrication system for the adequate lubrication

- Surfaces finish 2 microns (improved RA values can be obtained by using selected grade of grinding wheel applicable to material to be ground).