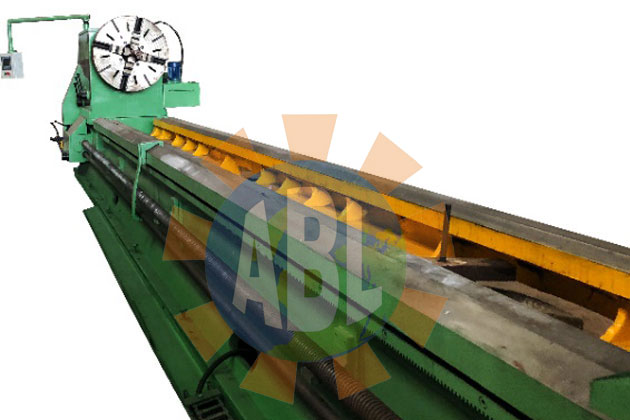

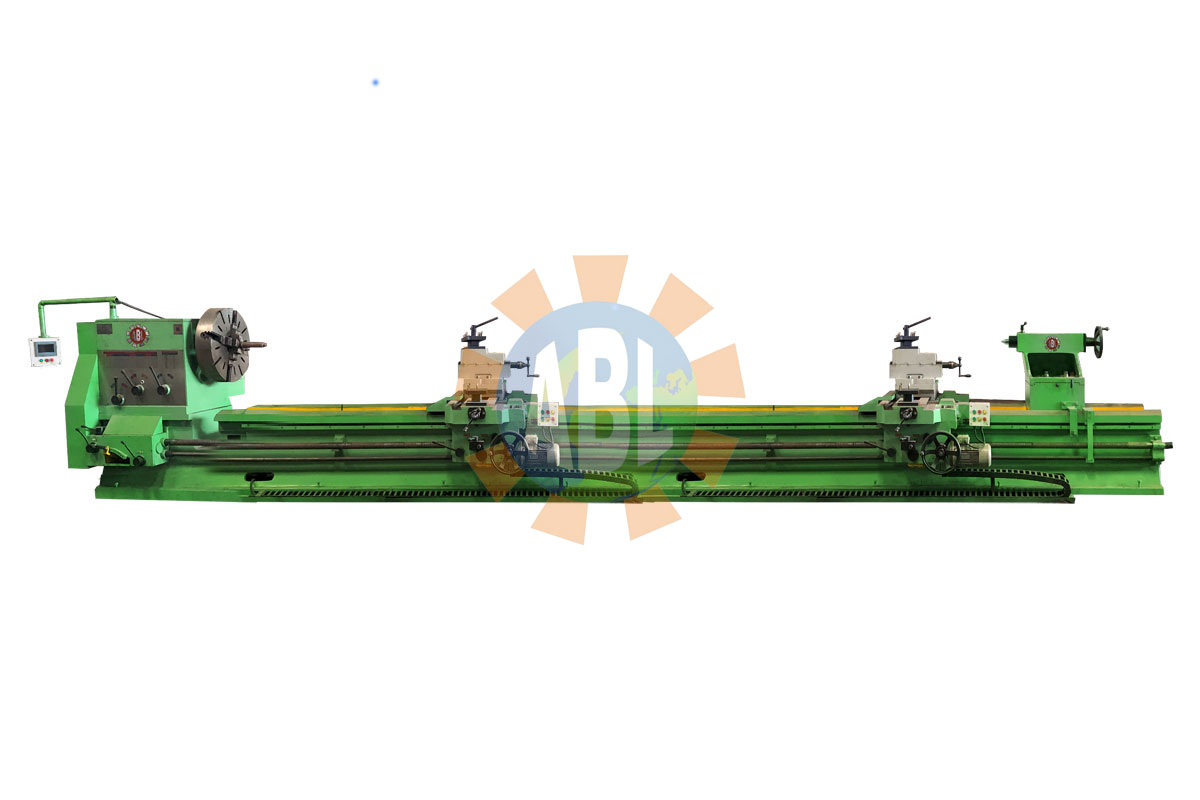

Extra Heavy Lathe, Twin Saddle Type

TWIN SAADLE UNITS ON BED / LONG BED LATHES/ EXTRA RIGID & STURDY ROLL TURNING/ ROTORS/ SHAFTS/ TURBINE REPAIRS

EXTRA Heavy Duty, LONG Bed, TWIN SADDLE TYPE, Horizontal Lathe Machines are designed to provide simultaneous cutting operations on very lengthy jobs using 2 units of Saddles, One at Front & the Second at Rear End of the Machine Bed. The machines can have very ideal utilizations in sectors like ~ repair shops of ship yards, oil & gas, power plants, cement, steel plants, paper mills, shipyards etc.

Product Specifications

| MODELS | EXTRA HEAVY DUTY – WITH 2 UNITS OF SADDLES ON THE MACHINE BED | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ABL-TS/50 | ABL-TS1/60 | ABL-TS1/80 | ABL-TS1/100 | ABL-TS2/60 | ABL-TS2/80 | ABL-TS2/100 | ABL-TS3/100 | ABL-TS3/120 | ABL-TS2/150 | ABL-TS3/200 | |||

| GENERAL CAPACITY | |||||||||||||

| ADMIT BETWEEN CENTERS | 5000 | 6000 | 8000 | 10000 | 6000 | 8000 | 10000 | 10000 | 12000 | 15000 | 20000 | ||

| BED WIDTH | 660 | 760 | 900 | 1050 | 1400 | 1930 | |||||||

| CENTER HEIGHT | 600 | 700 | 800 | 925 | 1200 | 1778 | |||||||

| SWING OVER BED | 1200 | 1400 | 1600 | 1850 | 2400 | 3500 | |||||||

| SWING OVER CROSS SADDLE | 800 | 850 | 1150 | 1350 | 2000 | 3000 | |||||||

| SWING IN GAP | 1400 | 1650 | 1950 | 2200 | 2800 | 4000 | |||||||

| MAX. PERMISSIBLE JOB WT. (KG) | 12000 | 20000 | 20000 | 22000 | 25000 | 27500 | 30000 | 40000 | 50000 | ||||

| SIZE OF CHUCK (4 JAWS) | 800 (32”) | 1000 (40”) | 1500 (60”) | 1800 (72”) | |||||||||

| SIZE OF CHUCK – TAIL STOCK (4 JAW) | 650 (26”) | 800 (32”) | 900 (36”) | 1000 (40”) | |||||||||

| NO. OF GUIDEWAYS ON BED | 2 NOS. | 3 NOS. | 3 NOS. | 4 NOS. | |||||||||

| HEAD STOCK | |||||||||||||

| MAIN SPINDLE BORE | 110 / 125 /150 | 150/ 200 | 150/ 200 | 150/ 200 | |||||||||

| MAIN SPINDLE NOSE | THREADED | THREADED | THREADED | THREADED | |||||||||

| MAIN SPINDLE TAPER (MT) | 5 / 6 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | ||||

| SPINDLE SPEEDS (NOS.) | 18 | 18 | 18 | 18 | |||||||||

| SPINDLE SPEED RANGE (RPM) | 8-200 / 4-100 | 4-100 / 2-50 | 2-50 | 2-30 | |||||||||

| TAIL STOCK | |||||||||||||

| TAIL STOCK QUILL DIA | 125 | 125 | 150 | 200 | 250 | 250 | |||||||

| TAIL STOCK QUILL TRAVEL | 300 | 300 | 300 | 350 | 350 | 350 | |||||||

| TAIL STOCK QUILL TAPER (MT) | 5 | 6 | 6 | 6 | 6 | 7 | |||||||

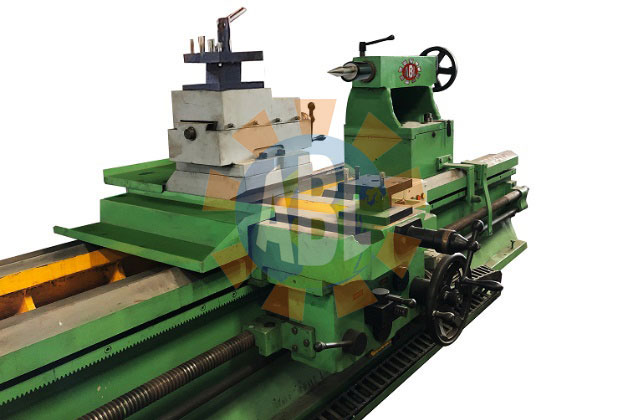

| SLIDE & CARRIAGE | |||||||||||||

| CROSS SLIDE TRAVEL | 600 | 700 | 800 | 1000 | 1200 | 1750 | |||||||

| TOP SLIDE TRAVEL | 250 | 250 | 250 | 250 | 300 | 400 | |||||||

| TAIL STOCK QUILL DIM. | 35 x 35 | 40 x 40 | 45 x 45 | 50 x 50 | 60 x 60 | ||||||||

| MOTORS (HP) | |||||||||||||

| MAIN MOTORS | 15 | 17.5 | 20 | 20 | 20 | 25 | 25 | 30 | 40 | 50 | 50 | 60 | 60 |

| RAPID MOTOR FOR SADDLE NO. 1 | 1 | 1 | 1 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | 3 | 3 | 3 | 3 |

| RAPID MOTOR FOR SADDLE NO. 2 | 1 | 1 | 1 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | 3 | 3 | 3 | 3 |

| COOLANT PUMP MOTOR | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.18 | 0.18 | 0.18 | 0.18 |

Standard Accessories

- 2 Units Of Motorized Saddles On The Machine Bed

- 4 Jaw Chuck

- Electrical Control Panel

- Operator’s Control Pendent

- Coolant System

- Machine Lamps

- Extra Heavy Steady Rest

- Foundation Bolt Kit

- Instruction & Maintenance Manual

Optional Accessories

- Rear End Chuck On Tail Stock

- Rapid Motor For Tail Stock

- Electro Hydraulic Brake For Main Motor

- VVF Drives For Motors

- Coolant System

- PLC Controls

- 2 Years Normal Maintenance Spare Set

Video Gallery

Image Gallery