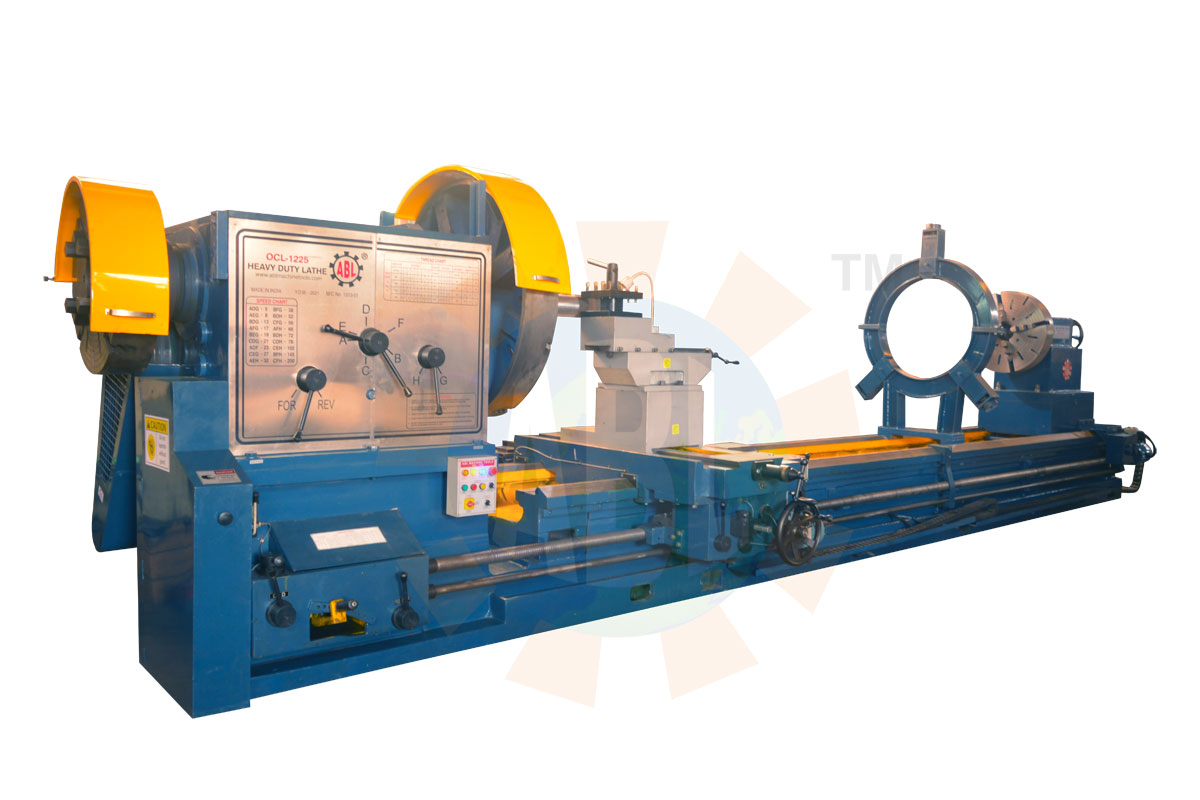

Extra Heavy, Roll Turning Lathe Machine

ALL GEARED TYPE [BULL-Master Series] – BEST SUITED FOR HEAVY STEEL MILL ROLL TURNING, SHIP REPAIR YARDS, CEMENT PLANTS ETC. FOR HEAVY TURNING, METAL CUTTING, MACHINING, OD GRINDING APPLICATIONS

‘BULLMASTER’ is the renowned series of “ABL” Extra Heavy Turning Roll Turning Lathes & the most ideal machine tools for precise and efficient machining of rotation symmetric workpieces with a diameter of up to 3M, length up to 20M and job weight up to 100 tons & more.

The machine is provided with extra heavy machine structure to withstand heavy job load & cut. The machine is equipped with twin extra heavy chucks at both ends for perfect gripping of the work piece. The load is also supported with monster steady rests with bearings to withstand the job load for smooth & heavy cut of the work piece.

Product Specifications

| MODEL | BULL-1.0 | BULL -1.2 | BULL -1.5 | BULL -2.0 | BULL -2.5 | BULL -3.0 |

|---|---|---|---|---|---|---|

| CAPACITY | ||||||

| DISTANCE BETWEEN CENTERS [#] | 3000 / 4000 / 5000 / 6000 / 8000 / 10000 / 12000 / 15000 / 20000 | |||||

| SWING OVER BED | 1000 | 1200 | 1500 | 2000 | 2500 | 3000 |

| CENTER HEIGHT | 500 | 600 | 750 | 1000 | 1250 | 1500 |

| BED WIDTH | 650 | 800 | 1000 | 1250 | 1500 | 1800 |

| SWING OVER CARRIAGE | 650 | 850 | 1175 | 1700 | 2150 | 2500 |

| SWING OVER CROSS SADDLE | 600 | 800 | 1125 | 1600 | 2025 | 2400 |

| SWING IN GAP | 1300 | 1500 | 1800 | 2500 | 3000 | 3400 |

| NO. OF MAIN SADDLE [#] | 1 / 2 | 1 / 2 | 1 / 2 | 1 / 2 | 1 / 2 | 1 / 2 |

| HEAD STOCK | ||||||

| 4 JAW HEAVY CHUCK [#] | 24” / 30” | 30” / 36” | 30” / 36” | 36” / 42” | 36” / 42” | 42” / 60” |

| MAIN SPINDLE BORE [#] | 105/125/150 | 105/125/150 | 105/125/150 | 105/125/150 | 105/125/150 | 105/125/150 |

| MAIN SPINDLE NOSE | THREADED | THREADED | THREADED | THREADED | THREADED | THREADED |

| MAIN SPINDLE TAPER [#] | MT 5 / MT 6 | MT 5 / MT 6 | MT 5 / MT 6 | MT 6 | MT 6 | MT 6 |

| NO. OF SPINDLE SPEEDS (NOS.) | 18 | 18 | 18 | 18 | 18 | 18 |

| TAIL STOCK | ||||||

| 4 JAW HEAVY CHUCK | 16” / 20” / 24” | 24” | 24” – 30” | 30” – 36” | 30” – 36” | 30” – 36” |

| TAIL STOCK RAPID MOTOR (HP) | 01 | 01 | 01 | 1.5 | 1.5 | 2.0 |

| MOTORS [#] | ||||||

| MAIN SPINDLE MOTOR (HP) | 15-20 | 15-25 | 15-30 | 20-50 | 25-70 | 30-100 |

| SADDLE MOTOR (HP) | 02 | 02 | 02 | 03 | 03 | 03 |

| CROSS SADDLE MOTOR (HP) | In Built | In Built | In Built | In Built | In Built | In Built |

| COMPOUND SLIDE MOTOR (HP) | 01 | 01 | 01 | 01 | 01 | 01 |

Note: # Option Available for selection or may vary.

Standard Accessories

- Electricals

- 4 Jaw Heavy Chucks

- Extra Heavy Steadies

- Chip Tray

- Coolant System

- Machine Lamp

- Foundation Bolt Kit

- Chuck Guard

- Instruction Manual

Optional Accessories

- 4 Jaw Chuck for Tail Stock

- Digital Readout Sys (DRO)

- Taper Turning Attachment

- Keyway Cutting Attachment

- Chip Conveyor System

- Tool Post Grinder

- Variable Speed Drives

- Extra Saddle Unit

- Motorized Saddle

- Motorized Tail Stock

- Large Dia. Face Plate

- 3 Jaw Chuck

Salient Features

- Heavily Cross Ribbed Cast Iron Bed

- Hardened Bed Guide ways up to 300 BHN

- Turcite Lined Compound Slideways

- High quality cast iron bed, head, tail stock, saddle etc

- Single Piece bed casting ensures high rigidity

- Alloy Steel & Hardened Gears

Video Gallery

Image Gallery

Note Before Enquiring

- While Enquiring, Confirm the required

- Distance Between Centers

- All dimensions are in MM, unless specified

- Higher/ Custom Sizes shall be provided on request

- Share Roll/Workpiece details, drawings while enquiring