Milling Machines

Milling Machines Manufacturers in India

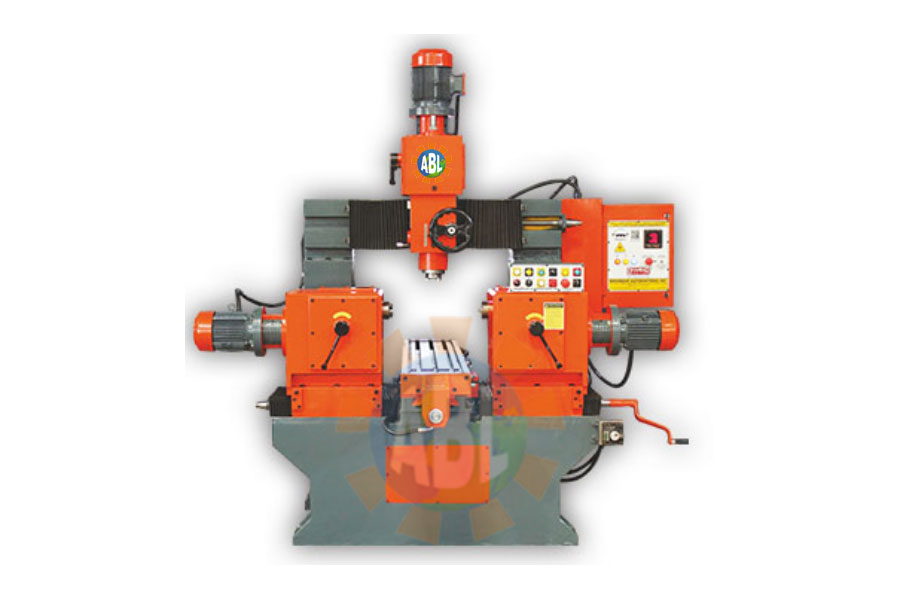

In the world of precision machining and industrial innovation, milling machines manufacturers in India play a crucial role in supplying advanced tools that drive modern manufacturing. Among the leading names, ABL Machine Tools has established itself as a trusted manufacturer, offering an extensive range of machine tools designed for reliability, accuracy, and high performance. With a strong presence in India, Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, ABL continues to deliver cutting-edge milling machines that meet global industrial standards.

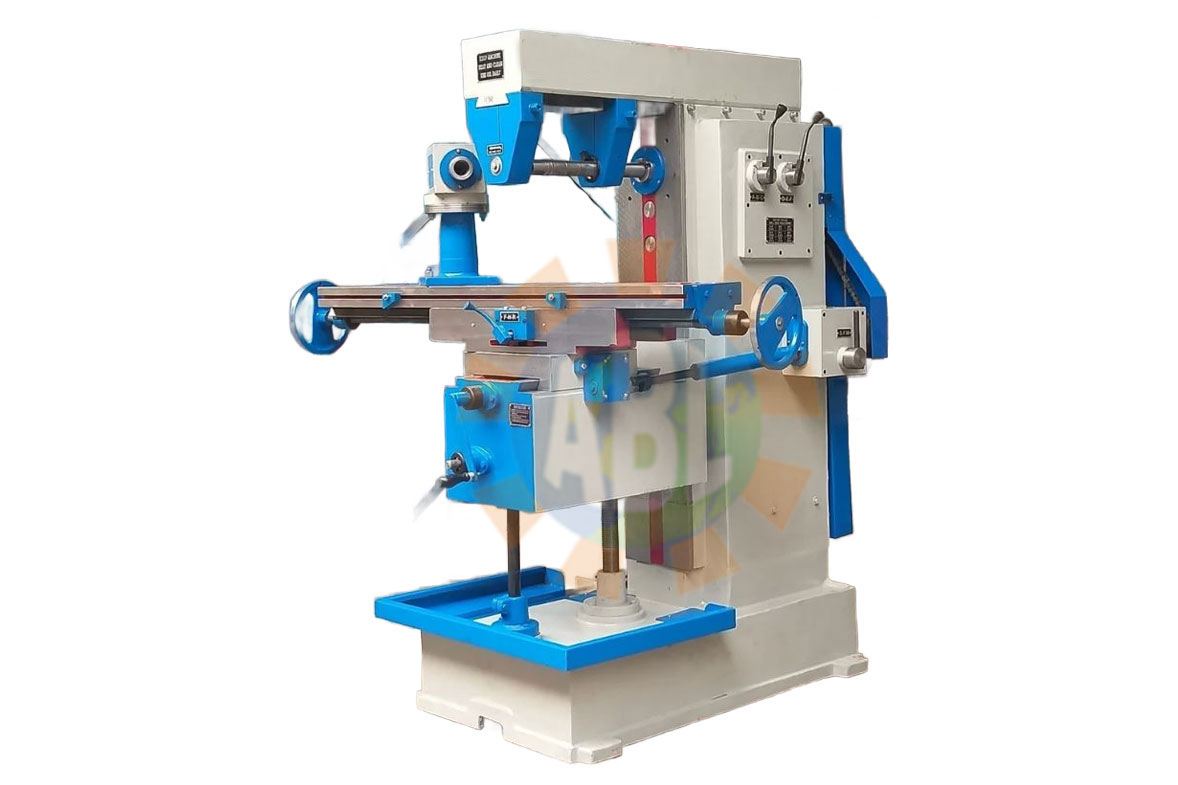

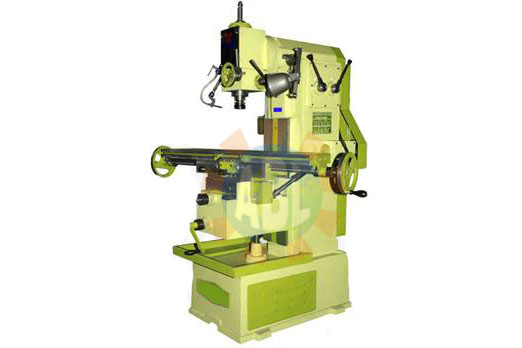

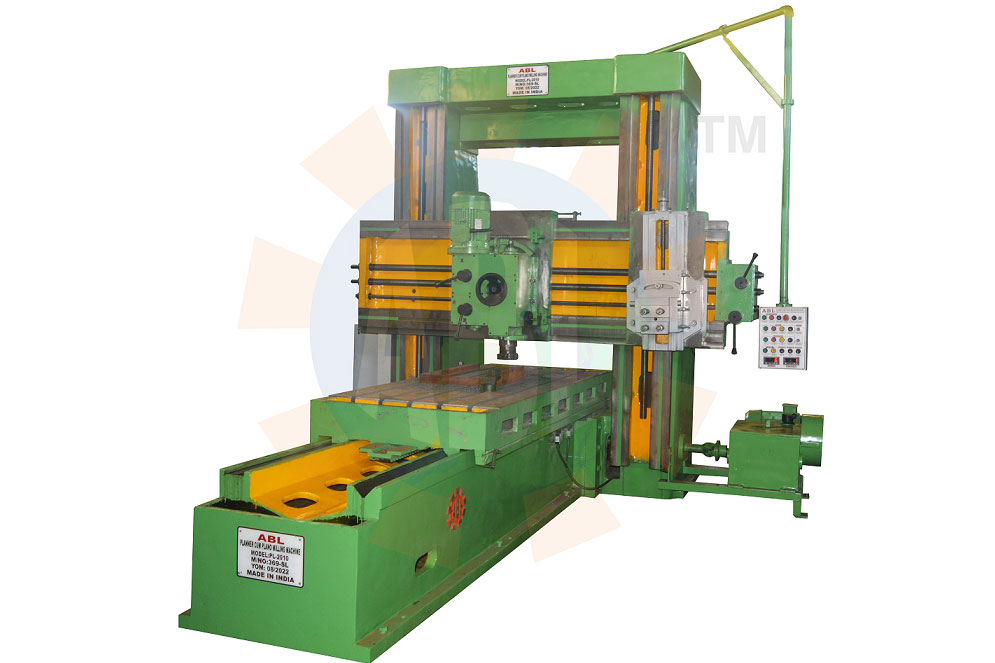

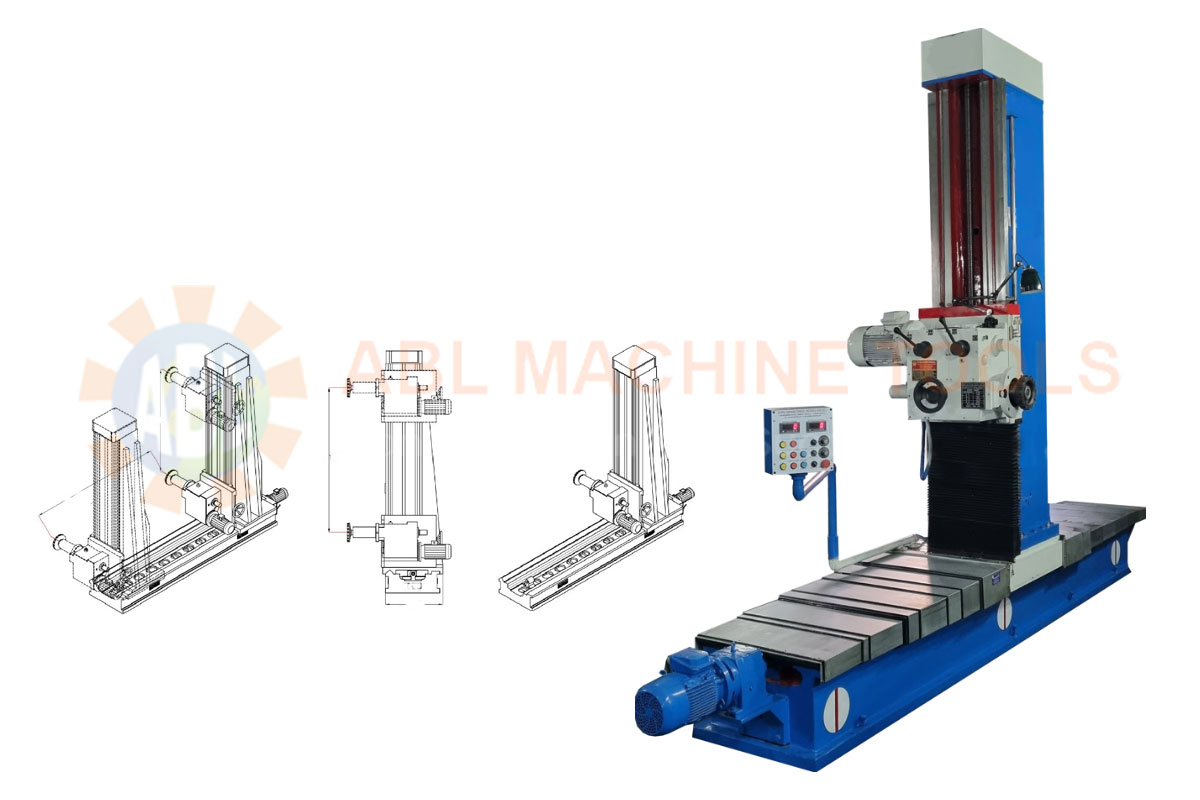

Wide Range of Milling Machines

ABL Machine Tools provides a comprehensive portfolio of milling machines tailored to diverse industrial applications. The product range includes vertical milling machines, horizontal milling machines, universal milling machines, and CNC milling machines. These machines are designed to perform complex operations such as slot cutting, gear cutting, drilling, and contouring with exceptional precision. Industries such as automotive, aerospace, shipbuilding, energy, oil & gas, and metal fabrication rely on ABL’s machines for efficiency and accuracy.

Customized Solutions for Every Manufacturing Need

Every manufacturing unit has unique requirements, and ABL Machine Tools specializes in offering custom-made milling machines. From spindle speed and table size to automation and control systems, the company designs machines to match specific production goals. This customized approach not only enhances productivity but also ensures cost-effectiveness and long-term operational value for clients.

Global Reach and Trusted Quality

With decades of expertise, ABL Machine Tools has expanded its reach far beyond India. Its machines are widely exported to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, where they are trusted for their durability and ability to withstand challenging industrial environments. Each machine undergoes strict quality checks and is built using premium-grade materials to guarantee consistent performance and a long service life.

Why Choose ABL Machine Tools?

- Extensive product portfolio of milling machines for all applications.

- Customized designs tailored to match client-specific requirements.

- Proven international presence with clients across the Middle East and North Africa.

- Focus on innovation, durability, and precision engineering.

- Strong customer support and long-term service commitment.

Milling Machines Manufacturers in Saudi Arabia, Milling Machines Manufacturers in UAE, Milling Machines Manufacturers in Qatar, Milling Machines Manufacturers in Kuwait, Milling Machines Manufacturers in Bahrain, Milling Machines Manufacturers in Oman, Milling Machines Manufacturers in Egypt

Frequently Asked Questions (FAQ) on Milling Machines

What is a milling machine?

A milling machine is an industrial tool used to remove material from a workpiece by rotating a cutting tool. It is widely used for shaping, drilling, slotting, gear cutting, and contouring metal, wood, or plastic surfaces with high precision.

What are the types of milling machines?

The most common types of milling machines include:

- Vertical Milling Machine

- Horizontal Milling Machine

- Universal Milling Machine

- CNC Milling Machine

- Turret Milling Machine

What industries use milling machines?

Milling machines are extensively used in industries like automotive, aerospace, shipbuilding, energy, oil & gas, defence, fabrication workshops, and general engineering.

What operations can be performed on a milling machine?

Typical operations include slot cutting, drilling, boring, reaming, contouring, gear cutting, and thread milling. CNC milling machines can also perform complex 3D machining operations.

How do I choose the right milling machine?

The selection depends on factors like the type of material, size of the workpiece, required precision, production volume, and automation level. ABL Machine Tools also provides custom-made milling machines tailored to your production goals.

Why are Indian milling machine manufacturers in demand globally?

Indian manufacturers such as ABL Machine Tools are known for delivering durable, cost-effective, and technologically advanced machines. Their wide export network, including Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, highlights their international reliability.

Can milling machines be customized?

Yes. Companies like ABL Machine Tools offer customized milling machines with variations in table size, spindle speed, automation features, and control systems to match specific industrial needs.

How do I maintain a milling machine?

Regular maintenance includes proper lubrication of moving parts, periodic alignment checks, cleaning chips and debris, replacing worn-out tools, and following the manufacturer’s service schedule. This ensures long life and consistent accuracy.