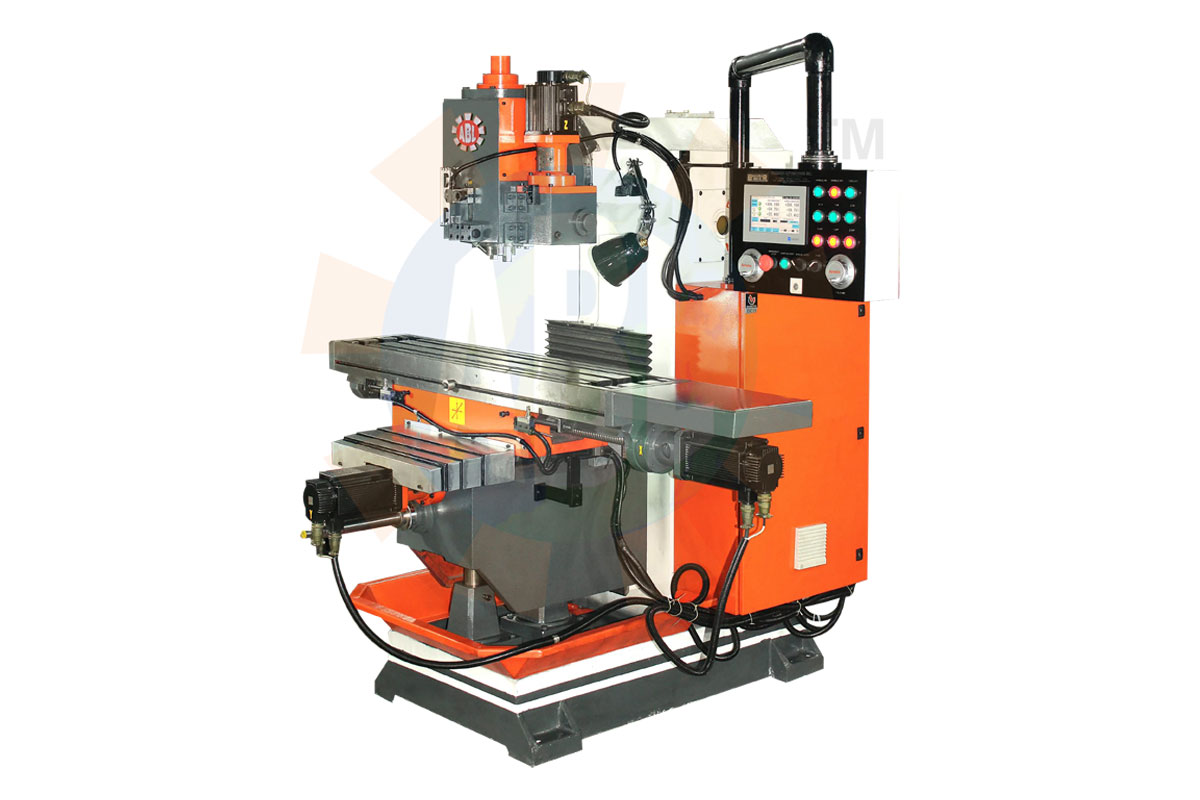

All Geared, Vertical Milling Machine

MILLING / FACING / GEAR CUTTING / KEY WAY MAKING / SLOTTING / RACK CUTTING

All Geared, Vertical Milling Machines are intended for massive & heaving duty operations and can perform even the most difficult add milling jobs with higher level of accuracy, productivity and hustle free operation.

Product Specifications

| MODEL | ABL-1VM | ABL-2VM | ABL-3VM | ABL-4VM | ABL-5VM | ABL-6VM | ABL-7VM |

|---|---|---|---|---|---|---|---|

| Working Surface (mm) | 1100×250 | 1300×300 | 1400×350 | 1600×360 | 1800×400 | 2000×450 | 2300×500 |

| Swivel (Deg.) +/- | 45 | 45 | 45 | 45 | Fix | Fix | Fix |

| T-Slot Nos. / Size | 3/16 | 3/16 | 3/20 | 3/20 | 3/20 | 3/20 | 5/20 |

| T-Slot Centre | 65 | 70 | 80 | 85 | 90 | 90 | 95 |

| Table Loading Capacity (Kg.) | 200 | 300 | 500 | 800 | 1100 | 1600 | 2500 |

| X-Longitudinal Travel (mm) | 500 | 700 | 800 | 900 | 1100 | 1200 | 1300 |

| Y-Cross Travel (mm) | 140 | 220 | 255 | 305 | 400 | 450 | 550 |

| Z-Vertical Travel (mm) | 300 | 400 | 400 | 500 | 550 | 600 | 700 |

| No. of Rapid Feeds | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| No. of Feeds | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| X-Y Rapid Feeds / Minute | 800 | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 |

| Z Rapid Feed / Minute | 175 | 175 | 175 | 175 | 175 | 175 | 175 |

| Range of X-Y Feeds / Min | 23-420 | 23-420 | 23-420 | 23-420 | 23-420 | 23-420 | 15-300 |

| Range of Z Feeds/ Min. | 3-70 | 3-70 | 3-70 | 3-70 | 3-70 | 3-70 | 3-70 |

| Spindle Taper | ISO 40 | ISO 40 | ISO 40 | ISO 40 | ISO 40 | ISO 40 | ISO 50 |

| No. of Spindle Speeds | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Range of Spindle Speeds (RPM) | 40-1100 | 40-1200 | 40-1200 | 40-1200 | 40-1200 | 40-1200 | 40-1200 |

| Max. Dist. Spindle to Table (mm) | 325 | 400 | 500 | 550 | 600 | 650 | 700 |

| Dist. Spindle Center to Column (mm) | 250 | 300 | 350 | 400 | 500 | 600 | 650 |

| Vert. Head Tilt (Deg.) +/- | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Manual Quill Travel (mm) | 95 | 95 | 95 | 95 | 95 | 95 | 100 |

| Main Motor (HP) | 2 | 3 | 5 | 7.5 | 10 | 10 | 12.5 |

| Feed Motor (HP) | 1.5 | 2 | 2 | 3 | 3 | 5 | 5 |

| Coolant Motor (HP) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Approx. Weight (kgs.) | 1800 | 2200 | 3200 | 3700 | 4500 | 5500 | 6500 |

Note: * All dimensions are in MM, unless specified. Higher Sizes shall be provided on request.

Standard Accessories

- Electrical

- Coolant System

- Machine Lamp

- Arbour with Hardened

- Bushes, Below Covers

- Maintenance Tool Box

- Instruction and maintenance manual

- Foundation Bolt Kit

Optional Accessories

- Numerically Controlled (NC)

- Digital Readout System (DRO)

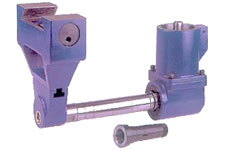

- Horizontal Milling Attachment

- Ram Type Head Attachment

- Duplex Attachment

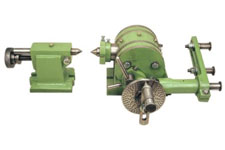

- Universal Dividing Head

- Rotary Table

- Milling Machine Vice

- Machine Lamp

- Electric Coolant Pump

Salient Features

- High rigidity of structure and drives.

- Convenient Design.

- Separate Drive for the spindle and the table movements.

- Single lever control of feeds & rapid traverse.

- Wide ranges of spindle speeds & feeds with high upper limits.

- Casting is high tensile strength & superior quality. Steel & Chemicals induced in casting.

- High rates of rapid table traverse while the spindle is running or at rest.

- Large longitudinal & traverse movements of table.

- Prolong Hardened Gears.

- All Parts are Interchangeable.

Video Gallery

Image Gallery

MILL VICE

D.R.O

ROTARY TABLE

HORZ. MILLING ATTACH