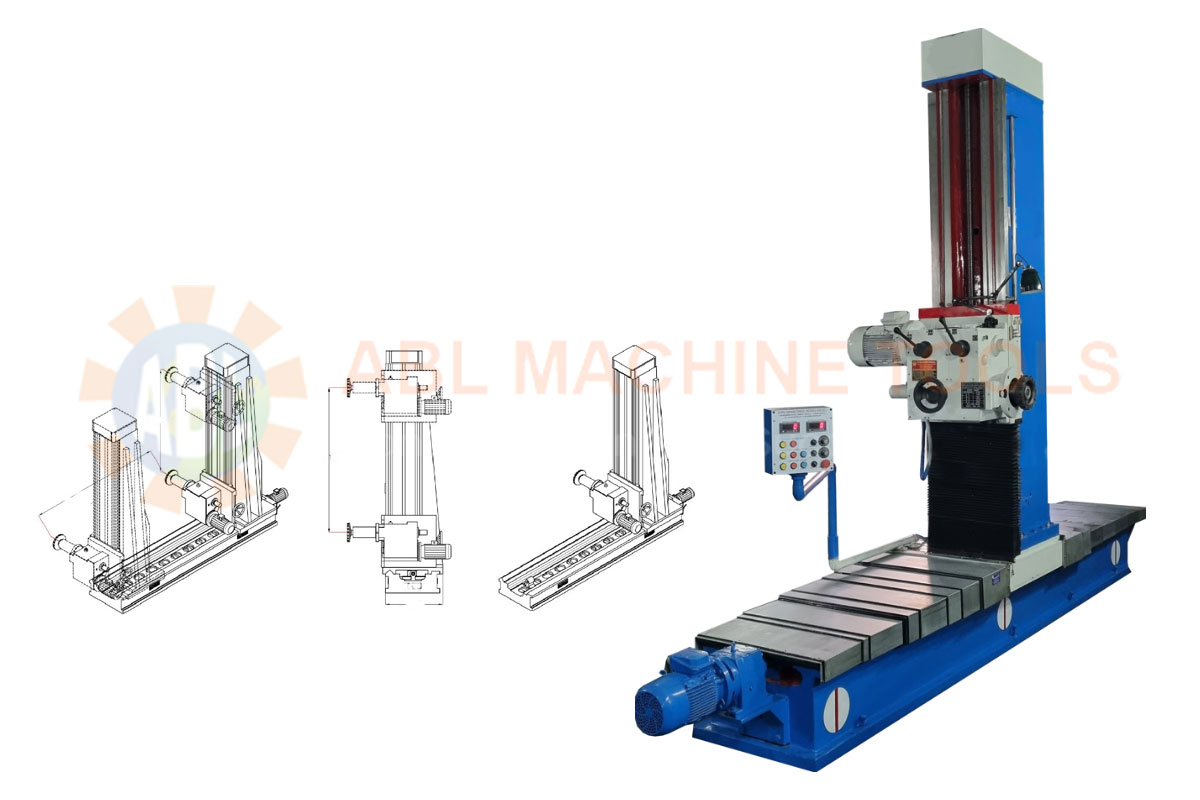

H-Beam End Face Milling Machine

END MILLER / FLOOR TYPE BORING MACHINE / TRAVELLING COLUMN / HEAVY MILL HEAD

H-Beam End Face Milling Machine is used to mill the cross-sectional end face of the Box-Beam and H beam. This multipurpose machine can also be used as Floor Type Borer Machine. It’s also known as a bevelling machine since you can mill the edges to create bevels at the end section. This machine can also perform milling operations on the end edges of the web and flange section and change the rough edges into a smoothened edge. Using the machine unit, you can perform highly efficient milling operations with higher degrees of precision.

Product Specifications

| MODEL | ABL-EM80 | ABL-EM125 | ABL-EM150 | ABL-EM200 | ABL-EM315 | ABL-EM350 | ABL-EM450 |

|---|---|---|---|---|---|---|---|

| GENERAL CAPACITY | |||||||

| Vertical Travel of Milling Head on Column | 1050 MM | 1150 MM | 1250 MM | 1350 MM | 1550 MM | 1850 MM | 2050 MM |

| Horizontal Travel of Column on Bed | 2250 MM | 2350 MM | 2550 MM | 3050 MM | 3550 MM | 4050 MM | 5050 MM |

| MILLNG HEAD CAPACITY | |||||||

| Milling Cutter Dia. on Mild Steel | 80 MM | 125 MM | 150 MM | 200 MM | 315 MM | 350 MM | 450 MM |

| No. of Spindle Speeds | 4 Nos. | 4 Nos. | 4 Nos. | 4 Nos. | 4 Nos. | 4 Nos. | 4 Nos. |

| Spindle Speed Range (RPM) | 120-500 | 120-500 | 120-500 | 100-400 | 75-300 | 75-300 | 25-100 |

| Spindle Motor Power | 3 HP | 5 HP | 7.5 HP | 10 HP | 15 HP | 20 HP | 30 HP |

| Spindle Diameter | 90 MM | 120 MM | 120 MM | 120 MM | 140 MM | 140 MM | 180 MM |

| Horizontal Traverse of Spindle | 80 MM | 110 MM | 110 MM | 125 MM | 140 MM | 150 MM | 150 MM |

| Traverse Mode | Manual | Manual | Manual | Manual | Manual | Manual | Manual |

| Main Spindle Taper | ISO 50 | ISO 50 | ISO 50 | ISO 50 | ISO 50 | ISO 50 | ISO 50 |

Standard Accessories

- MILLING HEAD on Column x 1 No.

- Electrical Panel & Control Pendent

- Machine Lamp & Lubrication Pump

- Maintenance Tool Box

- Instruction and maintenance manual

- Foundation Bolt Kit

Optional Accessories

- Numerically Controlled Milling Head with Servo Motors (NC) instead of Geared Milling Head on the Column

- Digital Readout System (DRO)

- Coolant System

- Set of Milling Cutters

- 2 Years Maintenance Spares

Salient Features

- Graded Casting of Bed, Column & Other major components

- Hardened Steel Gears in the Milling Head Unit

- Highly precise machined components ensuring best accuracies

- Sturdy & Well-Balanced Machine Structure ensuring no vibrations even at high depth cuttings