Threading Machines

Threading Machines Manufacturers in India

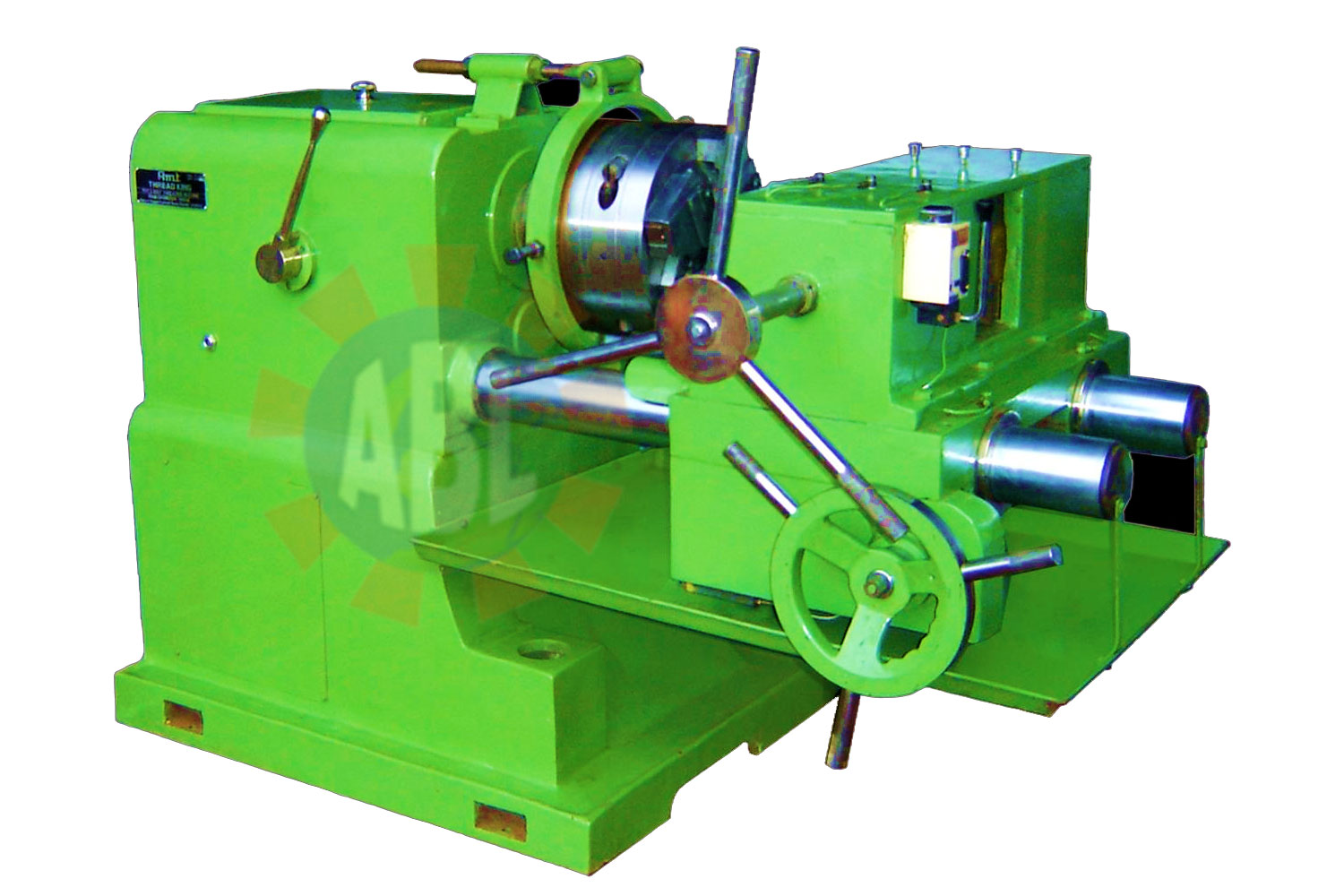

In the manufacturing sector, threading machines manufacturers in India are essential for producing high-precision threads on pipes, rods, bolts, and various components. Among the leading names in the industry, ABL Machine Tools has established itself as a trusted manufacturer, offering a wide range of threading machines designed for accuracy, durability, and efficiency. With a strong presence across India, Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, ABL Machine Tools delivers world-class solutions that meet both domestic and international industrial standards.

Wide Range of Threading Machines

ABL Machine Tools offers a comprehensive portfolio of threading machines suitable for diverse applications. The range includes pipe threading machines, automatic threading machines, bench-type threading machines, and CNC threading machines. These machines are engineered for precision threading operations on metal and non-metal components, ensuring high-quality results and minimal material wastage. Industries such as oil & gas, automotive, construction, heavy engineering, and shipbuilding rely on ABL threading machines for reliable and consistent performance.

Customized Solutions for Every Manufacturing Need

Every manufacturing facility has unique production requirements, and ABL Machine Tools specializes in offering custom-made threading machines. From thread size, spindle speed, and chuck capacity to automation features and digital controls, ABL designs machines tailored to meet specific production goals. This customization ensures improved productivity, reduced operational downtime, and enhanced overall efficiency for clients.

Global Reach and Trusted Quality

ABL Machine Tools has built a reputation for excellence in both domestic and international markets. Its threading machines are exported to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt, highlighting the brand’s commitment to quality and reliability. Each machine is manufactured using premium-grade materials and undergoes rigorous quality checks, ensuring durability, precision, and long-lasting performance even in demanding industrial conditions.

Why Choose ABL Machine Tools?

- Extensive range of threading machines for various industrial applications.

- Custom-made solutions to meet client-specific production requirements.

- Proven global presence with satisfied clients in India and the Middle East.

- Focus on precision engineering, durability, and innovation.

- Reliable after-sales support and maintenance services for optimal machine performance.

Threading Machines Manufacturers in Saudi Arabia, Threading Machines Manufacturers in UAE, Threading Machines Manufacturers in Qatar, Threading Machines Manufacturers in Kuwait, Threading Machines Manufacturers in Bahrain, Threading Machines Manufacturers in Oman, Threading Machines Manufacturers in Egypt

Frequently Asked Questions (FAQ) on Threading Machines

What is a threading machine?

A threading machine is a mechanical tool used to create external or internal threads on rods, bolts, pipes, and other components. It ensures high-precision threading for industrial and manufacturing applications.

What are the types of threading machines?

Common types include:

- Pipe Threading Machines

- Automatic Threading Machines

- Bench-Type Threading Machines

- CNC Threading Machines

What industries use threading machines?

Threading machines are widely used in industries like oil & gas, automotive, heavy engineering, construction, shipbuilding, and general manufacturing, where precision threads are essential.

What operations can be performed on threading machines?

Threading machines are used for cutting external threads, internal threads, pipe threading, and producing precise screw threads on rods, bolts, and other cylindrical components.

How do I choose the right threading machine?

The choice depends on factors such as thread size, material type, production volume, automation needs, and precision requirements. ABL Machine Tools also offers custom-made threading machines tailored to specific industrial needs.

Why are Indian threading machine manufacturers trusted globally?

Indian manufacturers, including ABL Machine Tools, are known for producing durable, cost-effective, and high-precision threading machines. Their exports to Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman, and Egypt highlight their international credibility and reliability.

Can threading machines be customized?

Yes. ABL Machine Tools provides customized threading machines with variations in thread size, spindle speed, chuck capacity, and automation features to match unique production requirements.

How should threading machines be maintained?

Regular maintenance includes proper lubrication of moving parts, cleaning after use, checking spindle alignment, replacing worn-out components, and following the manufacturer’s service guidelines to ensure long machine life and consistent performance.